Base plate processing device, coating device and coading method

A technology for a substrate processing device and a coating device, which can be applied to a device for coating liquid on a surface, a coating device, a photoengraving process coating device, etc., can solve problems such as adverse effects on film thickness uniformity, changes in horizontal balance, and the like, Achieve the effect of improving position accuracy and uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

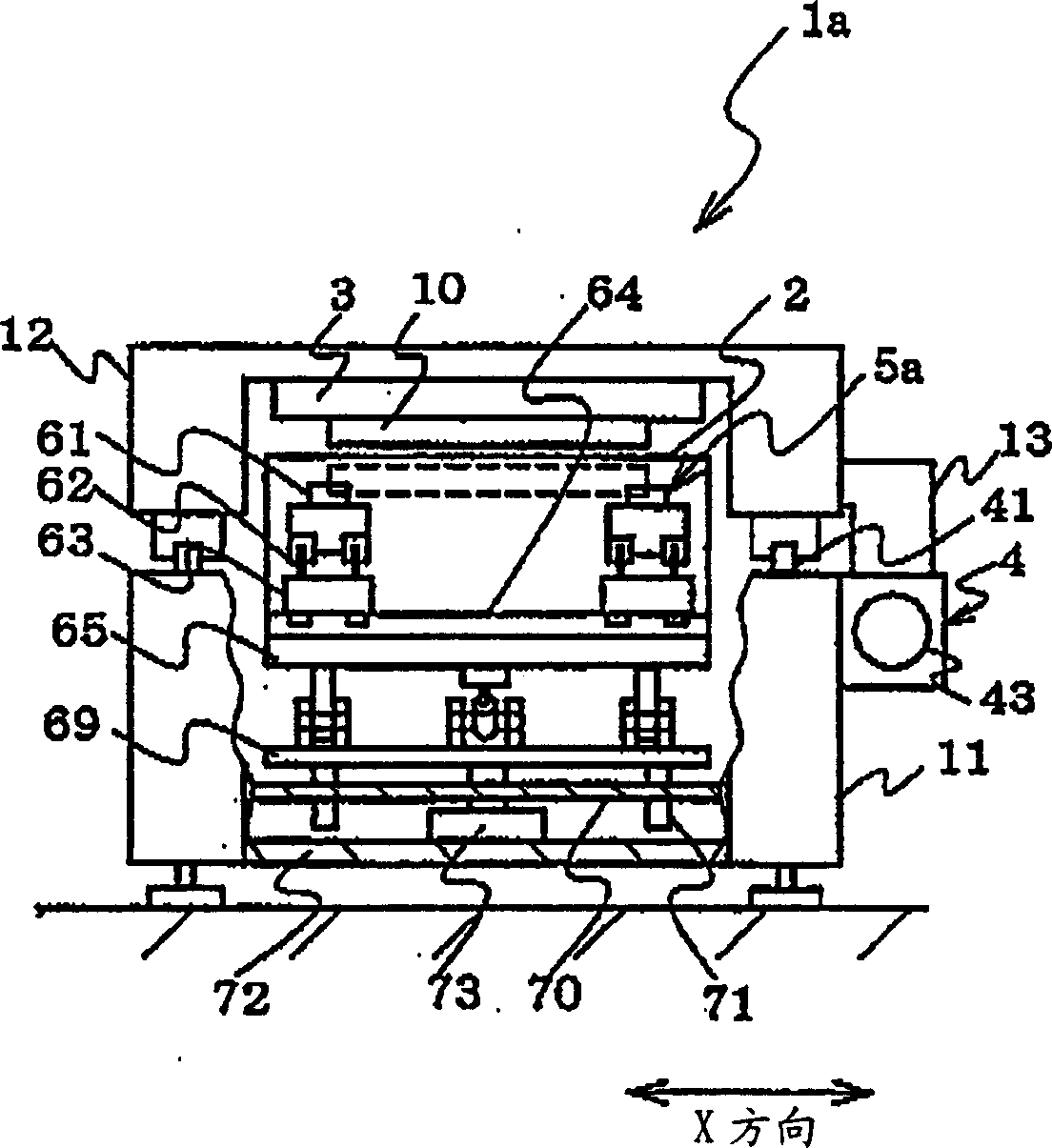

[0041] Hereinafter, various embodiments of the present invention will be described with reference to the drawings.

[0042] [Substrate Processing Equipment]

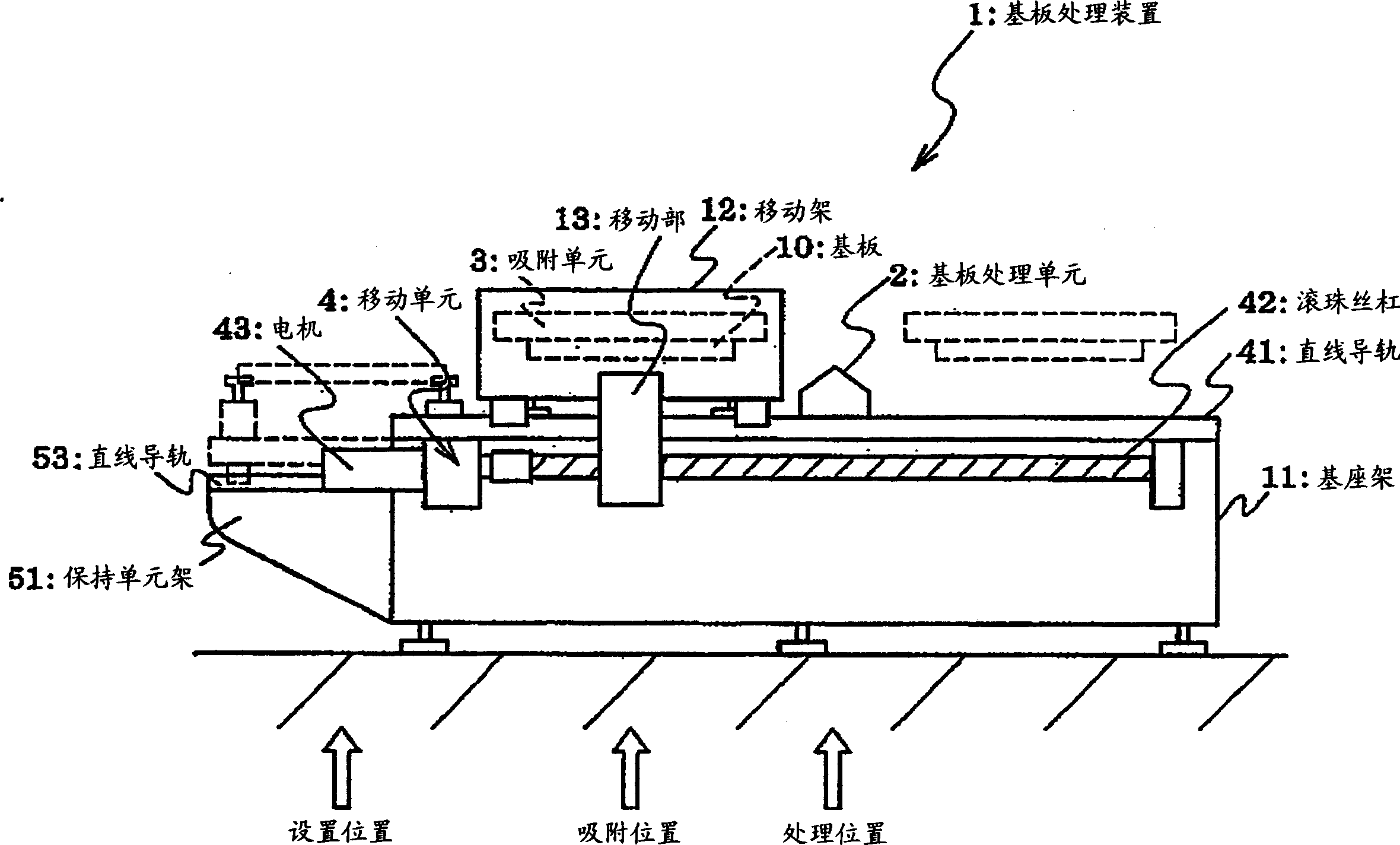

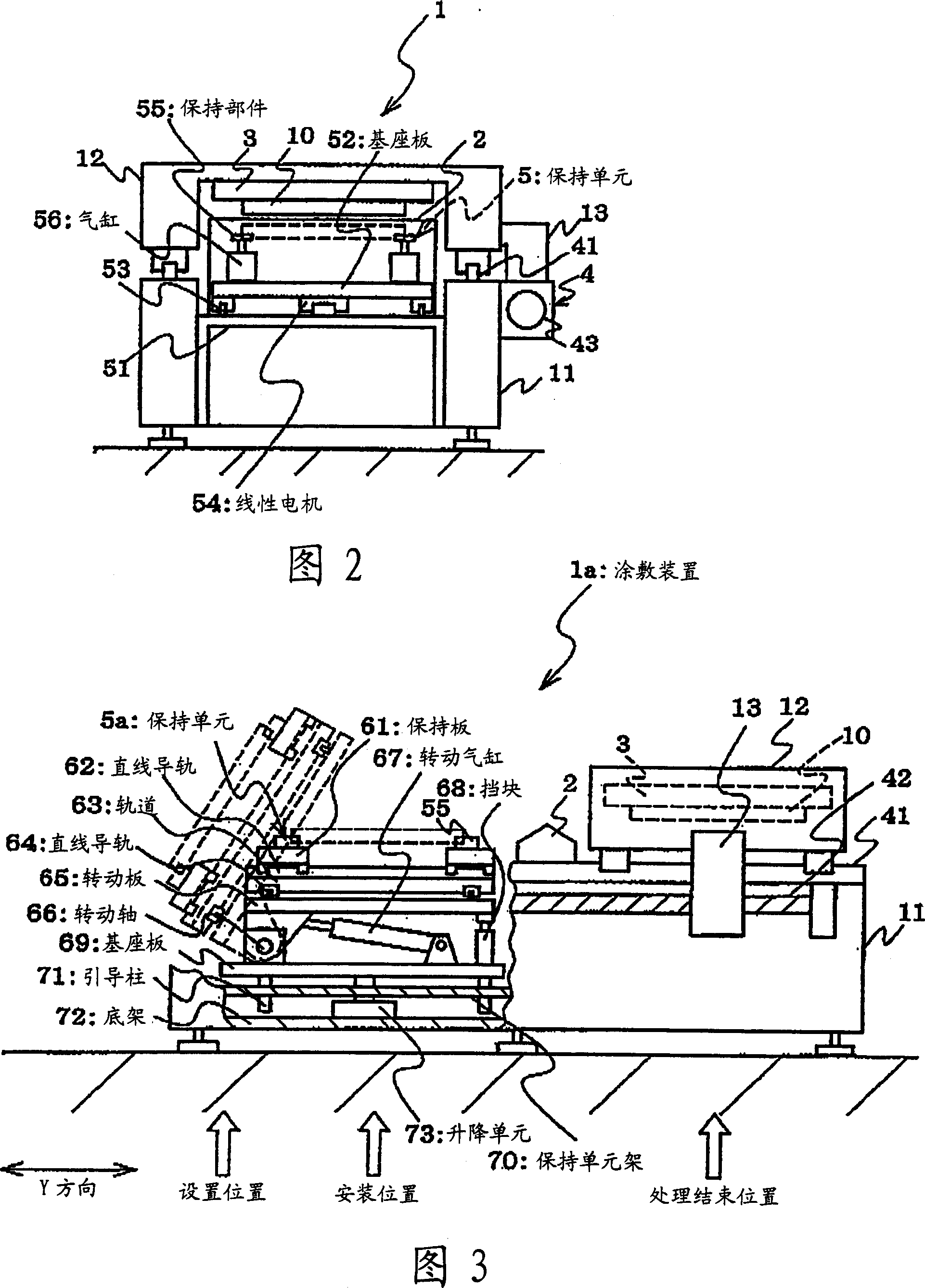

[0043] First, refer to figure 1 2, an embodiment of the substrate processing apparatus of the present invention is described.

[0044] figure 1 FIG. 2 is a schematic side view of the substrate processing apparatus, and FIG. 2 shows a schematic front view thereof.

[0045] Such as figure 1 As shown, the substrate processing apparatus 1 has: a substrate processing unit 2 arranged on the base frame 11; an adsorption unit 3 arranged on the moving frame 12; a moving unit for moving the moving frame 12 horizontally on the base frame 11 4; a holding unit 5 that can detachably hold the substrate 10; and a control unit not shown.

[0046] The substrate processing unit 2 is used to process the substrate 10 with the surface to be processed facing downward. The substrate processing unit 2 is provided substantially in the cente...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap