Method of high-officieny treating spacecraft impelling agent of spacecraft and its special eequipment

A special equipment and propellant technology, applied in the field of efficient treatment of aerospace propellant wastewater, can solve problems such as unsatisfactory effect and low treatment efficiency, and achieve the effects of low cost, high waste degradation rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

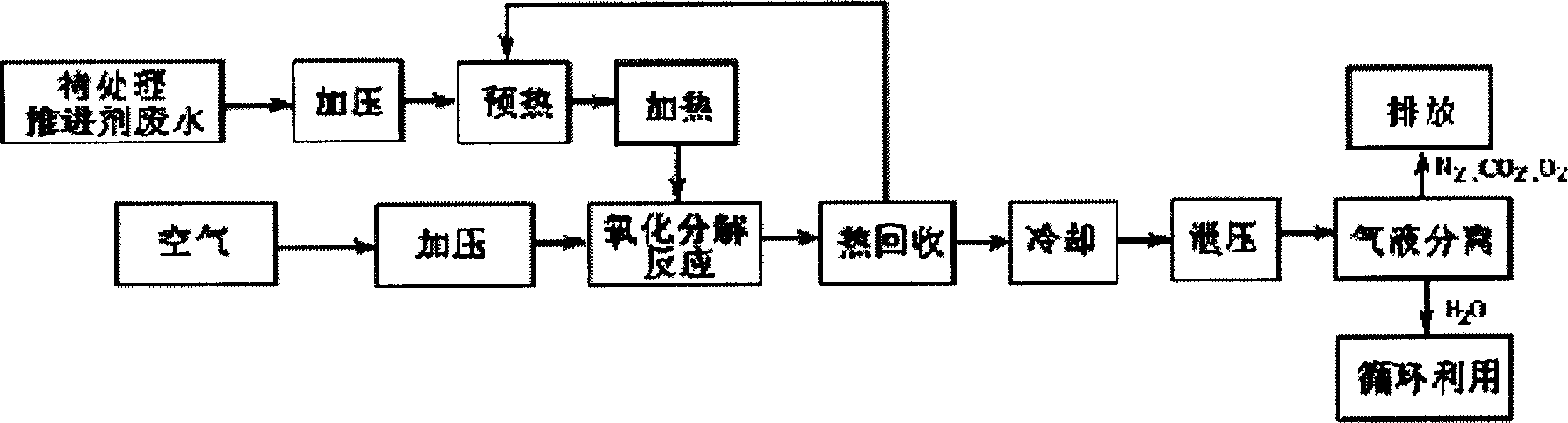

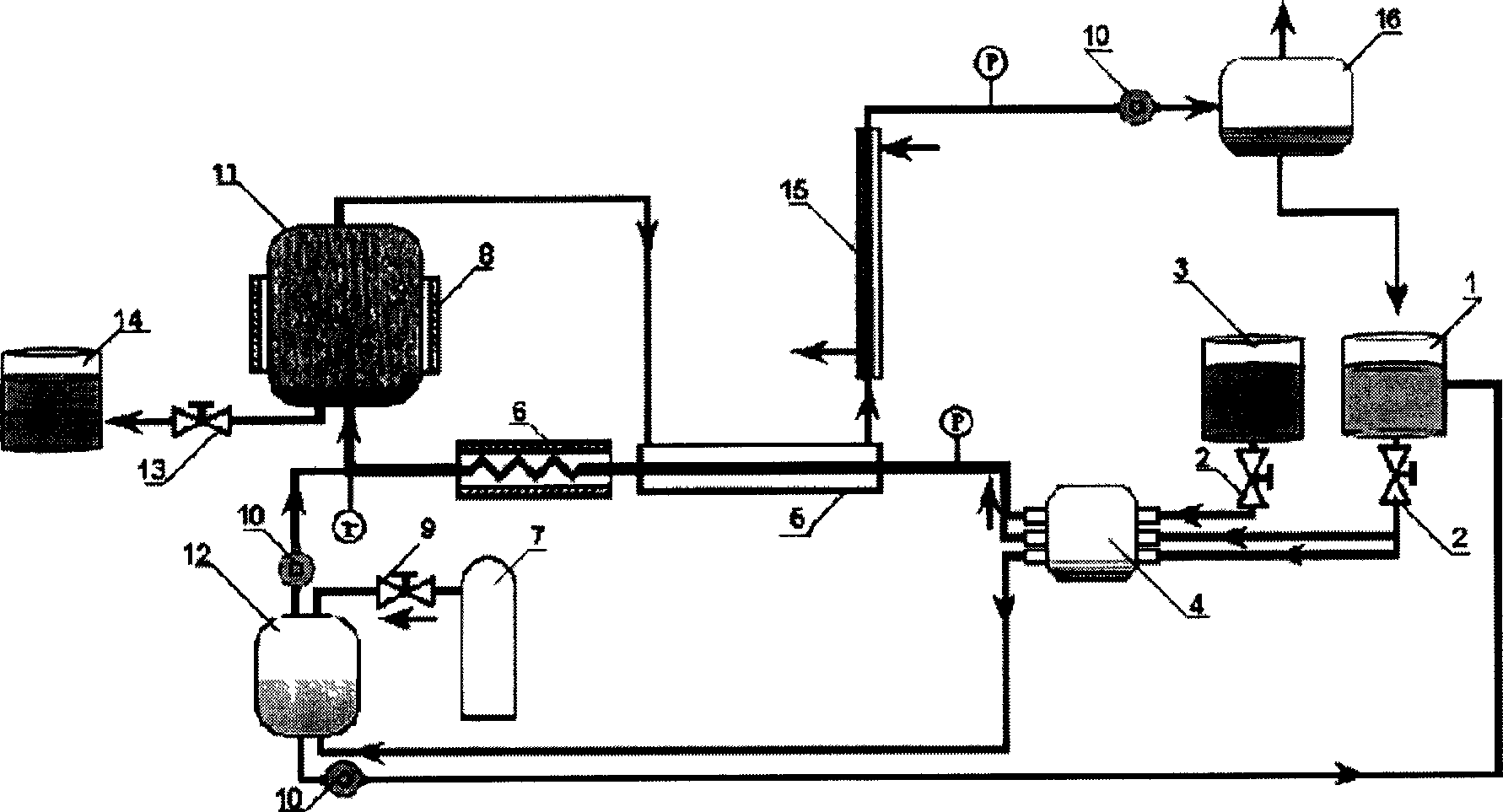

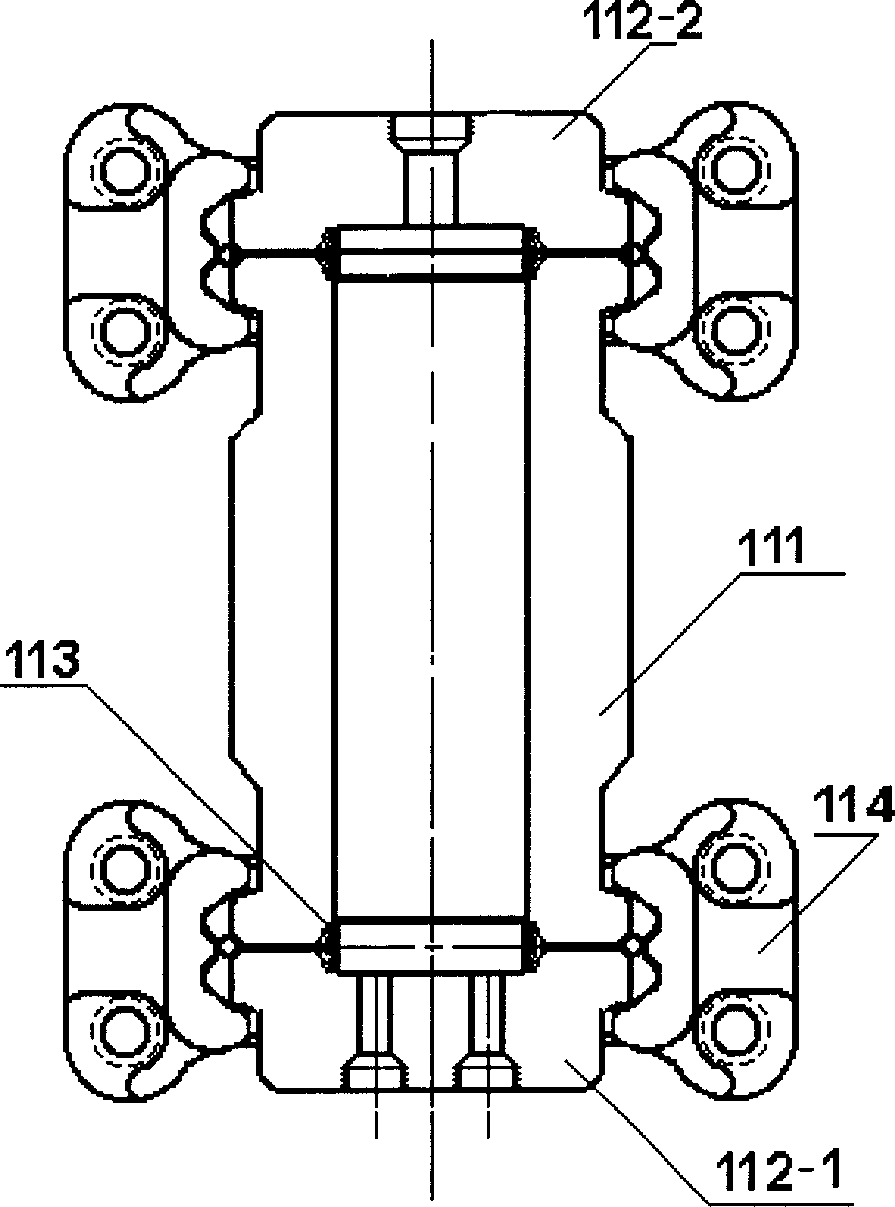

[0028] The inventive method: as figure 1 , 2 As shown, the propellant wastewater whose content of unsymmetrical dimethylhydrazine has been preliminarily determined is injected into the wastewater storage tank 3, and at the same time, deionized water is injected into the clean water storage tank 2. By adjusting the propellant wastewater inlet of the high-pressure metering pump 4 and the flow rate of the deionized water for dilution, the bias in the wastewater to be treated in the wastewater preheater made of the heat recovery cylinder 5 and the preheating furnace 6 can be made from its outlet. The concentration of dimethylhydrazine is kept in the range of 2g / L~10g / L. The content of unsymmetrical dimethylhydrazine in the propellant waste water adopted in this embodiment is 3g / L, therefore does not need to be diluted, directly pressurizes to 28.0±0.1×10 with the flow rate of 24L / h by the high-pressure metering pump 4. 6 After Pa, it is sent to the waste water preheater for preh...

Embodiment 2

[0047] The difference with Example 1 is: the product after the treatment——CO 2 , N 2 and H 2 After O etc. are discharged from the outlet of the autoclave 11, they can also directly enter the cooler 15 for cooling. After cooling, the effluent product with a temperature of 30±5°C is released to normal pressure through the pressure relief valve, and then passes through the gas-liquid separator 16 for further decompression. Gas and liquid separation. Such as Image 6 As shown, the output port of the autoclave 11 of the equipment of the present invention can be directly connected to the cooler 15; the output port of the waste water preheater formed by the preheating furnace can be directly connected to the input port of the autoclave 11.

[0048] The unsymmetrical dimethylhydrazine content is 15g / L in the propellant waste water that adopts in the present embodiment, therefore needs to dilute, by regulating the flow rate of the propellant waste water entrance of high-pressure met...

Embodiment 3

[0051] The difference from Example 1 is:

[0052] The propellant wastewater flow rate provided by the high-pressure metering pump 4 to the pipeline used in this embodiment is 40 L / h, and the wastewater stream gradually flows from the bottom of the autoclave 11 to the top outlet in about 65 seconds. The organic pollutants contained in it can be oxidized and decomposed, and the decomposition rate reaches 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com