Sagneto-optical recording medium and its production method

A technology of magneto-optical recording and manufacturing method, applied in magnetic recording, optical recording/reproducing, data recording, etc., can solve the problems of inability to reproduce magnetic signals, decrease the amplitude of readout signals, etc., and achieve the effect of improving jitter characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

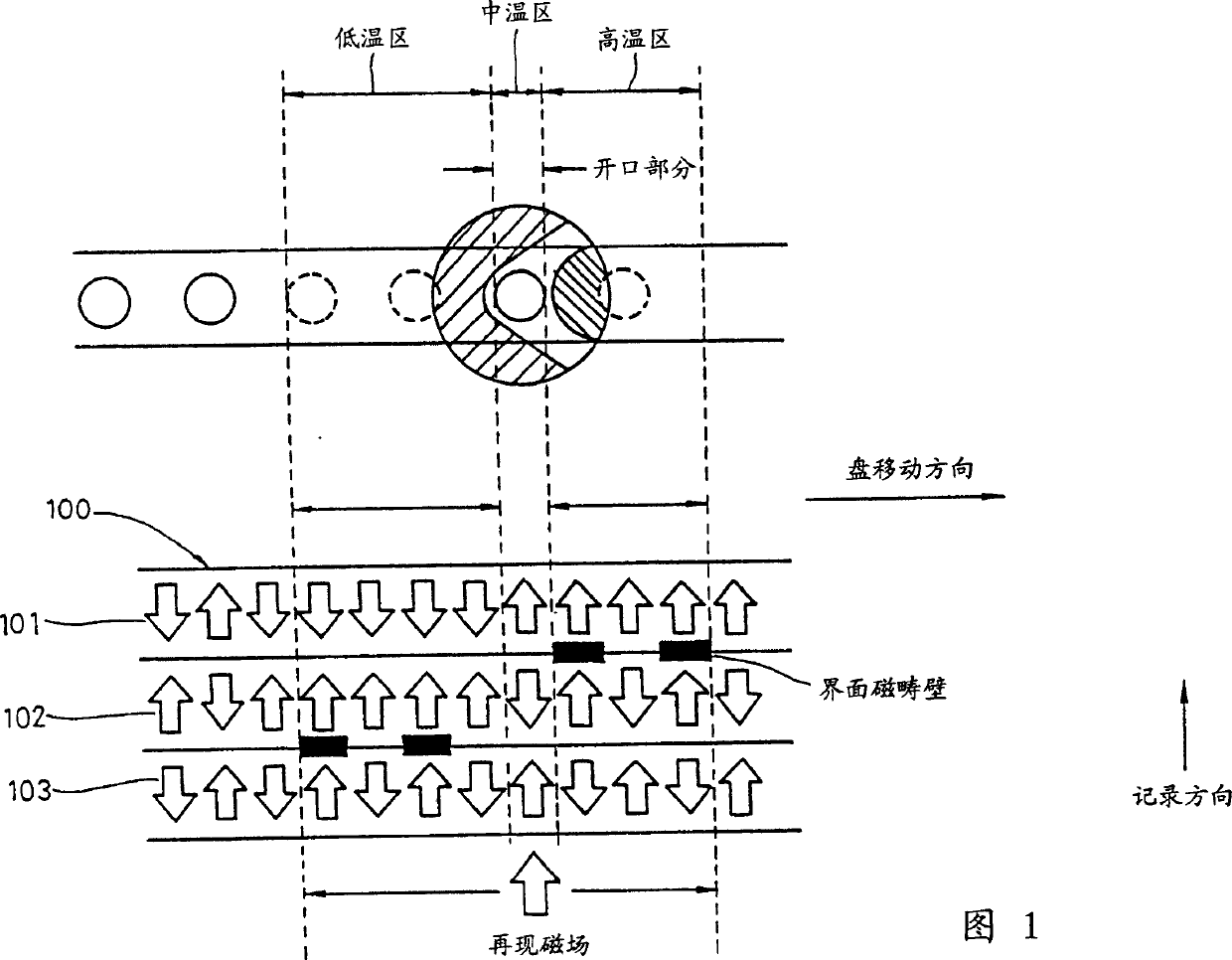

[0038] An embodiment of the present invention will be described below with reference to the accompanying drawings. In all subsequent schematic diagrams of the embodiments, the same or corresponding parts are indicated by the same reference numerals.

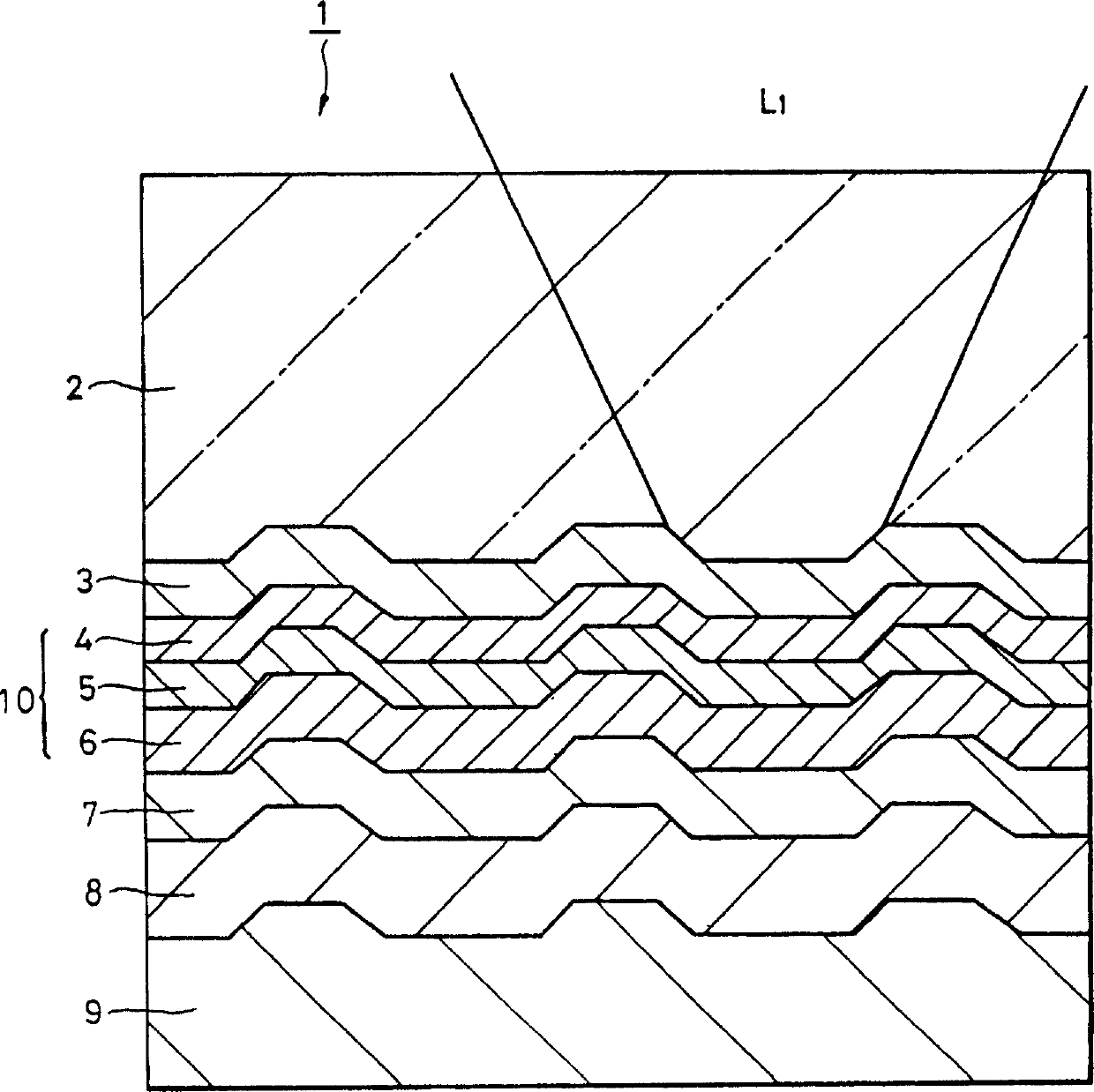

[0039] First, a magneto-optical disk according to an embodiment of the present invention will be described. Fig. 2 shows a magneto-optical disk according to the first embodiment.

[0040] As shown in FIG. 2, the magneto-optical disk 1 according to this embodiment is formed by sequentially laminating a first dielectric layer 3, a first magnetic layer 4, a second magnetic layer 5, and a third magnetic layer on a main plane of a disk base 2. 6. The second dielectric layer 7, the reflective layer 8 and the protective layer 9 are formed.

[0041] The disc base 2 is produced by molding a resin material into a disc shape, for example, by an injection molding method. For example, glass 2P or the like or a synthetic resin material such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com