High pressure water bath laser ablation and processing method

A laser ablation and processing method technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of not being able to simultaneously improve the mechanical stress distribution of the workpiece, the negative impact of the workpiece surface morphology, shape defects and stress defects, etc. , to achieve the effects of suppressing large-scale diffusion, improving smoothness and processing accuracy, and improving surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

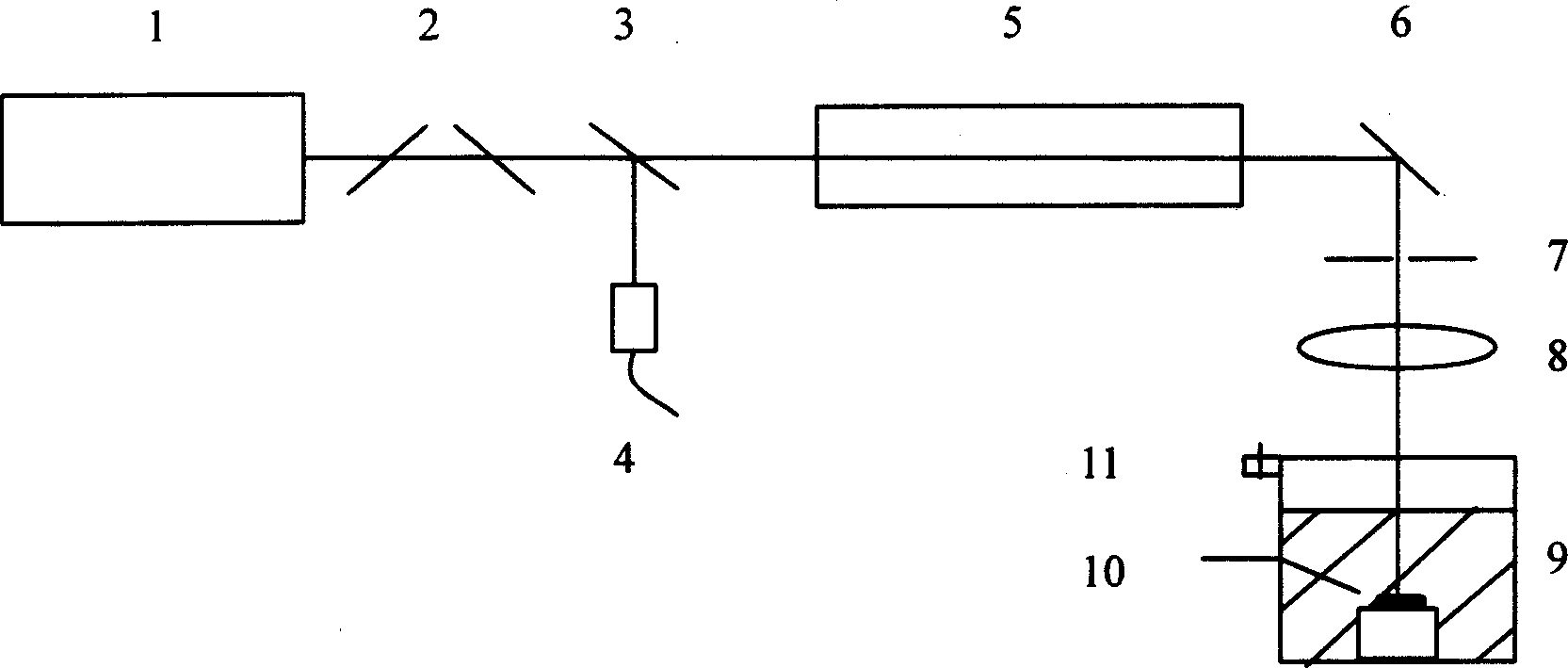

[0013] figure 1 It is a layout diagram of an embodiment of the high-pressure water bath laser ablation and processing method of the present invention, wherein: Laser 1 adopts the 532nm second harmonic output of Spectron-SL454G-Nd:YAG solid-state laser. After the laser passes through the JD-1 attenuator 2, part of the laser light is split by the beam splitter 3 and then monitored by the power meter 4. The transmitted laser light is shaped by the spatial filter 5 . 6 is a 45° full-reflection film, which deflects the incident laser light by 45°, and then converges to the workpiece 10 through the small hole 7 and the lens 8 . The workpiece 10 is immersed in the container 9 filled with water and added 6 atmospheres through the valve 11, and the water surface is higher than the top of the workpiece by 5-10 mm.

[0014] In this embodiment, silicon wafers are drilled and cut, and good results are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com