Reinforced daily ceramic manufacturing process

A manufacturing process and daily-use technology, applied in applications, clay products, household utensils, etc., can solve the problems of difficult molding, high requirements for kiln equipment, high firing temperature, etc., achieve uniform distribution of strengthening phases, and expand firing temperature Range, the effect of lowering the firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0038] Specific embodiments of the present invention are now described in the following:

[0039] The manufacturing process method of strengthening and strengthening daily-use porcelain of the present invention comprises the following steps:

[0040] A. Set the chemical formula of the oxide composition of the special daily-use porcelain body and enamel and the raw material formula of the porcelain body and enamel:

[0041] a. The oxide composition chemical formula and raw material formula of porcelain blank are:

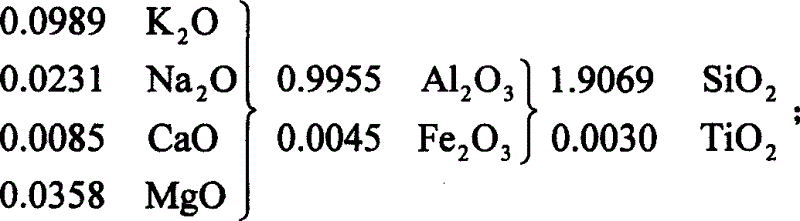

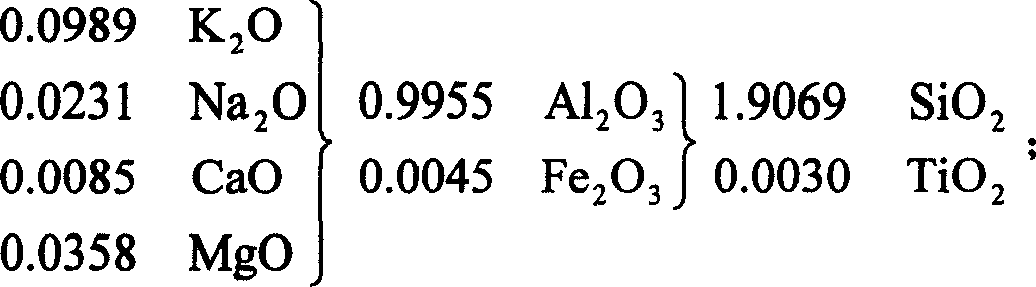

[0042] a). The chemical formula of the oxide composition of the porcelain body is:

[0043]

[0044] b). The raw material formula (wt%) of the porcelain body:

[0045] Porcelain clay (produced in Yimen, Yunnan) 70

[0046] Kaolin (from Xuanwei) 9

[0047] Industrial alumina 21

[0048] Talc powder (produced in Guangxi) 2-3

[0049] Additive yttrium oxide 1-3%;

[0050] The chemical composition of each raw material of the porc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com