Method for separating carbon dioxide dissolvent from gas mixture

A technology of gas mixture and carbon dioxide, which is applied in the direction of carbon compounds, separation methods, and dispersed particle separation, can solve the problems of high energy consumption and unsatisfactory purification degree, and achieve the effects of low energy consumption, reduced corrosion, and large absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

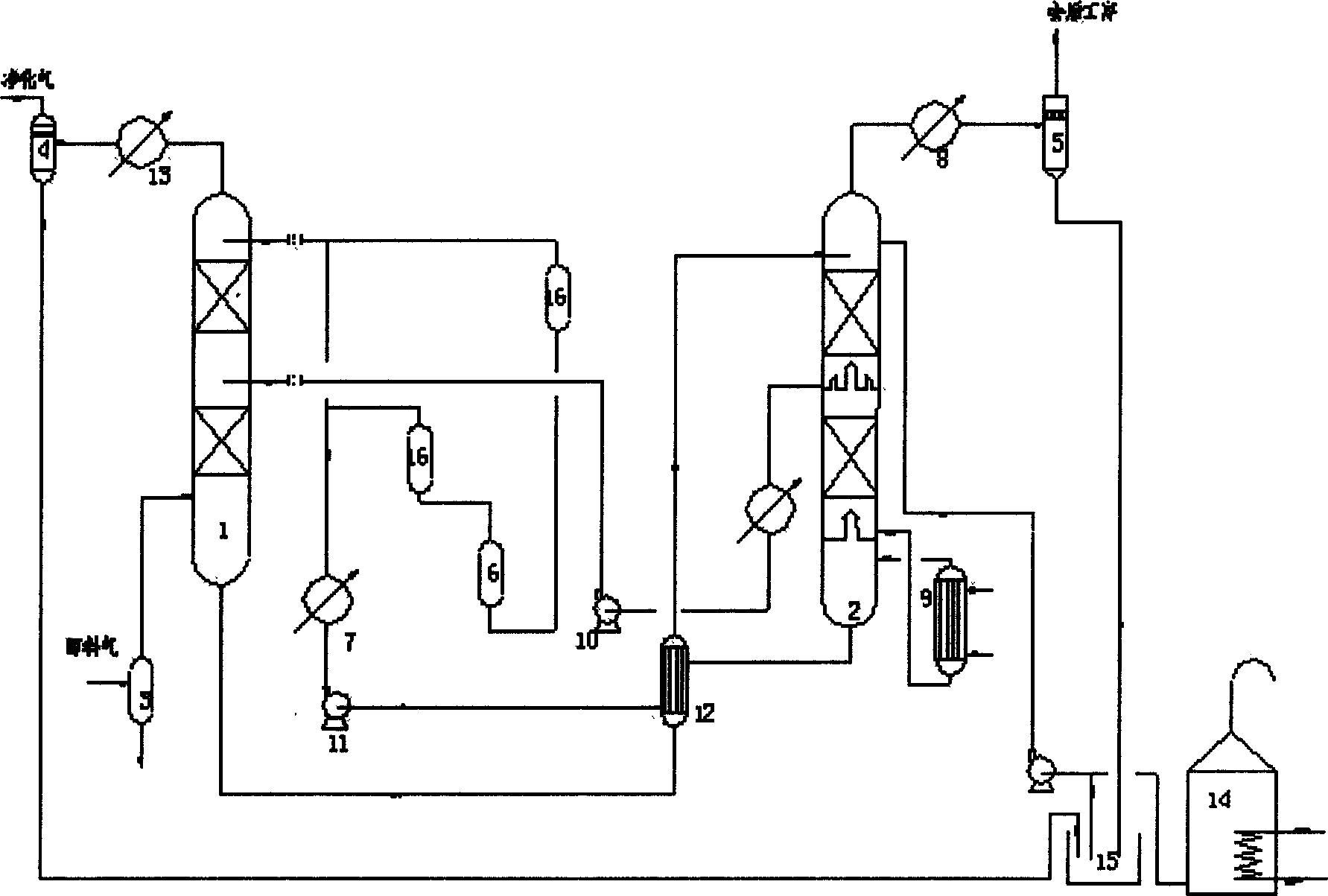

[0029] The raw material gas is the shift gas from a medium-sized nitrogen fertilizer plant, in which the carbon dioxide content is about 26%. After cooling to room temperature and depressurizing to 0.8Mpa, the attached figure 1 The shown process removes carbon dioxide, and the regeneration energy of all solutions is the same, and the absorption effects of different solutions are shown in Table 1.

[0030] Preface

[0031] As can be seen from Table 1: compared with the activated MDEA solution, the solvent used in the present invention can reduce the carbon dioxide content in the purified gas to below 1% under the lower partial pressure of carbon dioxide.

Embodiment 2

[0033] The gas condition is the same as that of Example 1, but the regeneration power is changed, and the results are shown in Table 2.

[0034] Preface

[0035] As can be seen from Table 1: compared with the MEA method, the required regeneration energy consumption of the solvent used in the present invention is much lower.

Embodiment 3

[0037] Attached figure 1 In the process shown, the composition of the solution is: MDEA25% + TBDEA4% + AMP5% + TBMEA5% + MMEA3% + water 58%, the pressure of the shift gas is 0.8Mpa, which contains 22% of carbon dioxide, and the flow rate is 17000Nm 3 / h, the carbon dioxide in the purified gas is 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com