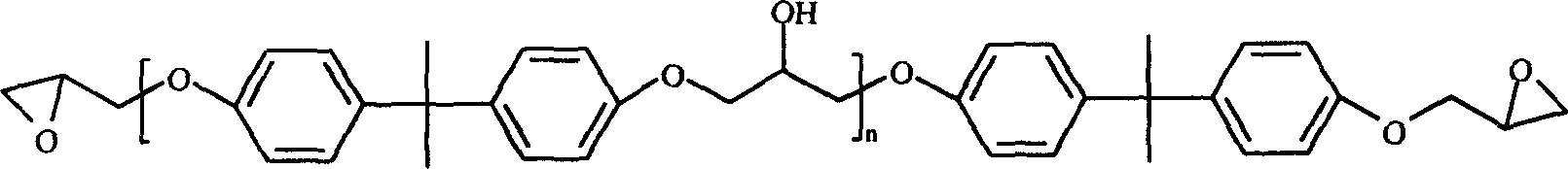

High purity low molecule biphenol A epoxy resin synthetic process

A technology for epoxy resin and low molecular weight, applied in the field of synthesizing high-purity low-molecular-weight epoxy resin, can solve the problems of complex production process, difficulty in desalination, large amount of waste water, etc., and achieve simple production process, high product purity and low viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Bisphenol A 0.1mol, epichlorohydrin 1.0mol and K 2 CO 3 0.2 mol was put into the reaction kettle, stirred, and the temperature was raised to 110° C., and the reaction progress was monitored by gas chromatography for 3 hours, and the reaction was completed. The reaction was filtered and the filter cake was washed with a small amount of epichlorohydrin. The filter cake is KCl and KHCO 3 Mixtures that can be processed for reuse or other uses. Combine the filtrate and washing liquid, and distill under reduced pressure to remove excess epichlorohydrin (which can be recycled). When steaming until no more distilled out, add 50ml of toluene and continue vacuum distillation to remove residual epichlorohydrin, and the distillation substrate is the product. The Ep340 content of the epoxy resin obtained in this way is greater than 90%, which is higher than the products (the Ep340 content is about 80%) made by the existing technology.

[0009] The reaction schedule described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com