Active infrared CCD weld seam detecting method

An active infrared and weld seam detection technology, which is used in measuring devices, optical testing of flaws/defects, material analysis by optical means, etc. Parameter extraction and other issues, to achieve the effect of simple and fast image processing algorithm, stable lighting model, and reducing the influence of mutual radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

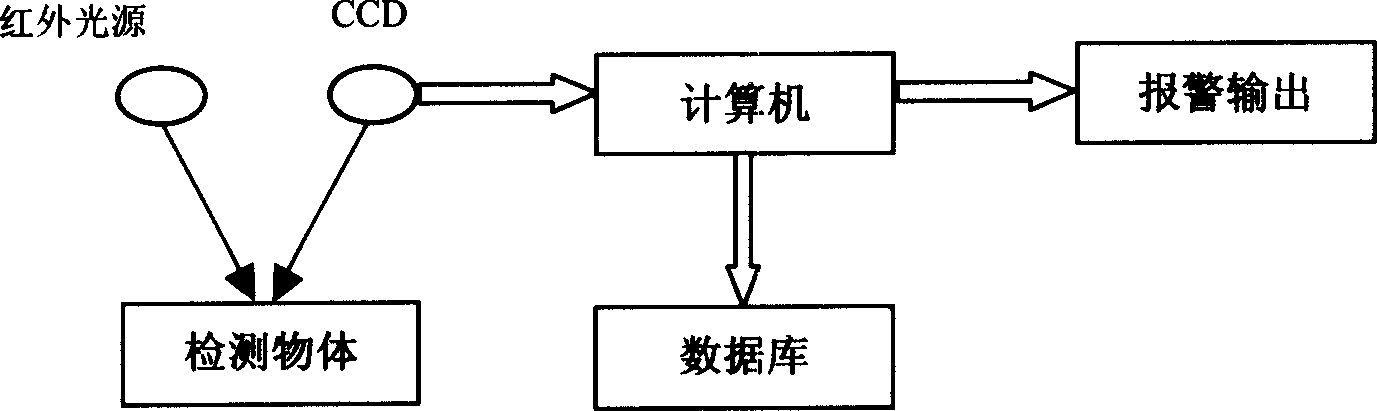

[0021] The process of the active infrared CCD welding seam detection method of the present invention is as follows figure 1 Shown. Firstly, a CCD camera is used to obtain the infrared image of the weld. The infrared light-emitting diode is selected as the infrared light source, and the infrared light-emitting diode array is irradiated on the surface of the weld. CCD is used as the detector to obtain the active infrared image. The CCD has a special filter for infrared CCD. Mirror, transmit near-infrared light, cut off visible light; infrared light-emitting diode working voltage is 3V, working current is 10uA, the peak wavelength of light is 940nm, the beam angle is 34°, and the infrared image of the weld is obtained as image 3 Shown.

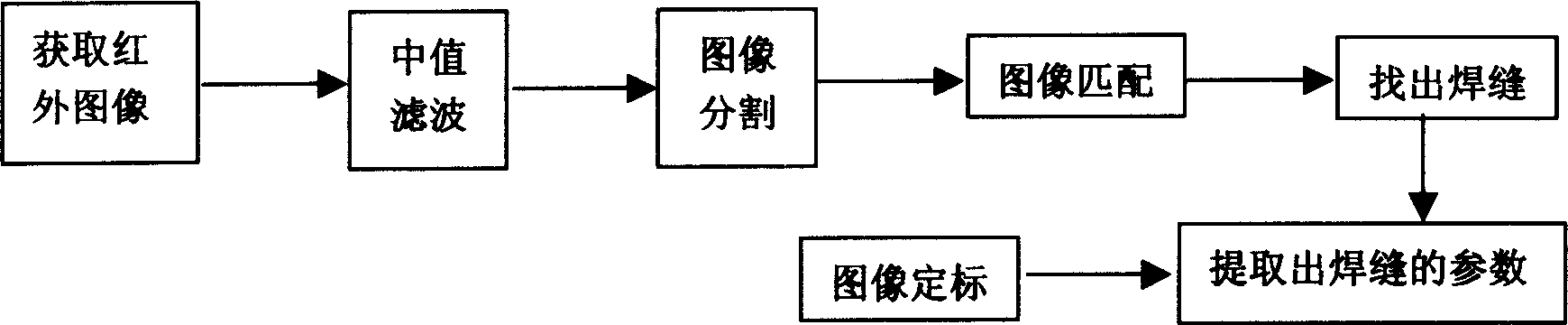

[0022] Then the computer pairs image 3 The infrared image of the weld is analyzed and processed, and the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com