Environment protection type phosphate free engine oil

An engine oil and environmental protection technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of three-way catalyst poisoning, etc., and achieve the effects of high cost performance, good compatibility, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1: Using VG100 # Base oil as benchmark, in VG100 # In the base oil, first add the ashless detergent dispersant T-154 (polyisobutenyl succinimide) with a total amount of 7.5% (percentage by weight), the overbased calcium sulfonate ash detergent dispersant, and the defoamer , fully reconcile, and then divide the above oil sample into two equal parts, which are recorded as 0 # ,1 # . 0 # Add 2% (weight ratio) zinc dialkyldithiophosphate (ZDDP) anti-oxidation and anti-wear multi-effect agent in the sample again, 1 # Add 2% (weight ratio) of fluorinated graphite anti-wear agent and 0.5% alkyl diphenylamine antioxidant to the sample, fully reconcile, prepare an engine oil containing no phosphorus compound, and carry out differential thermal analysis (DSC) resistance Oxidation performance test, the results are shown in Table 1:

[0009]

Embodiment 2

[0010] Embodiment 2: Using VG32 # Urea dewaxed base oil as benchmark, in VG32 # In the urea dewaxed base oil, first add ashless detergent and dispersant T-154 (polyisobutenyl succinimide) with a total amount of 7.5%, overbased calcium sulfonate with ash detergent and dispersant, and defoamer. Fully reconcile, then add 2% fluorinated graphite anti-wear agent and 0.5% alkyl diphenylamine antioxidant to the above oil samples respectively, fully reconcile, prepare engine oil containing phosphorus-free compounding agent, carry out high-temperature cleaning and dispersing agent and anti-oxidant Oxidation rapid coke plate test, the results are shown in Table 2:

[0011] project

first trial

second test

third test

Phosphorus-free engine oil of the present invention

2

2

2

[0012] 1. Engine oil rating: 1 is the best, 10 is the worst

[0013] 2. Tentative criteria for engine oil quality evaluation: high-grade (SG / SH / SJ...

Embodiment 3

[0016] Embodiment three: using a certain amount of VG10 # Light dewaxed oil (its pour point is -40°C, viscosity at -25°C is 86mm 2 / s, flash point (open) 162°C) and a certain amount of high-viscosity bright oil (VG1000 # , pour point -8°C, flash point above 250°C), according to the empirical formula for lubricating oil blending, blend 5W / 20 Newton base oil.

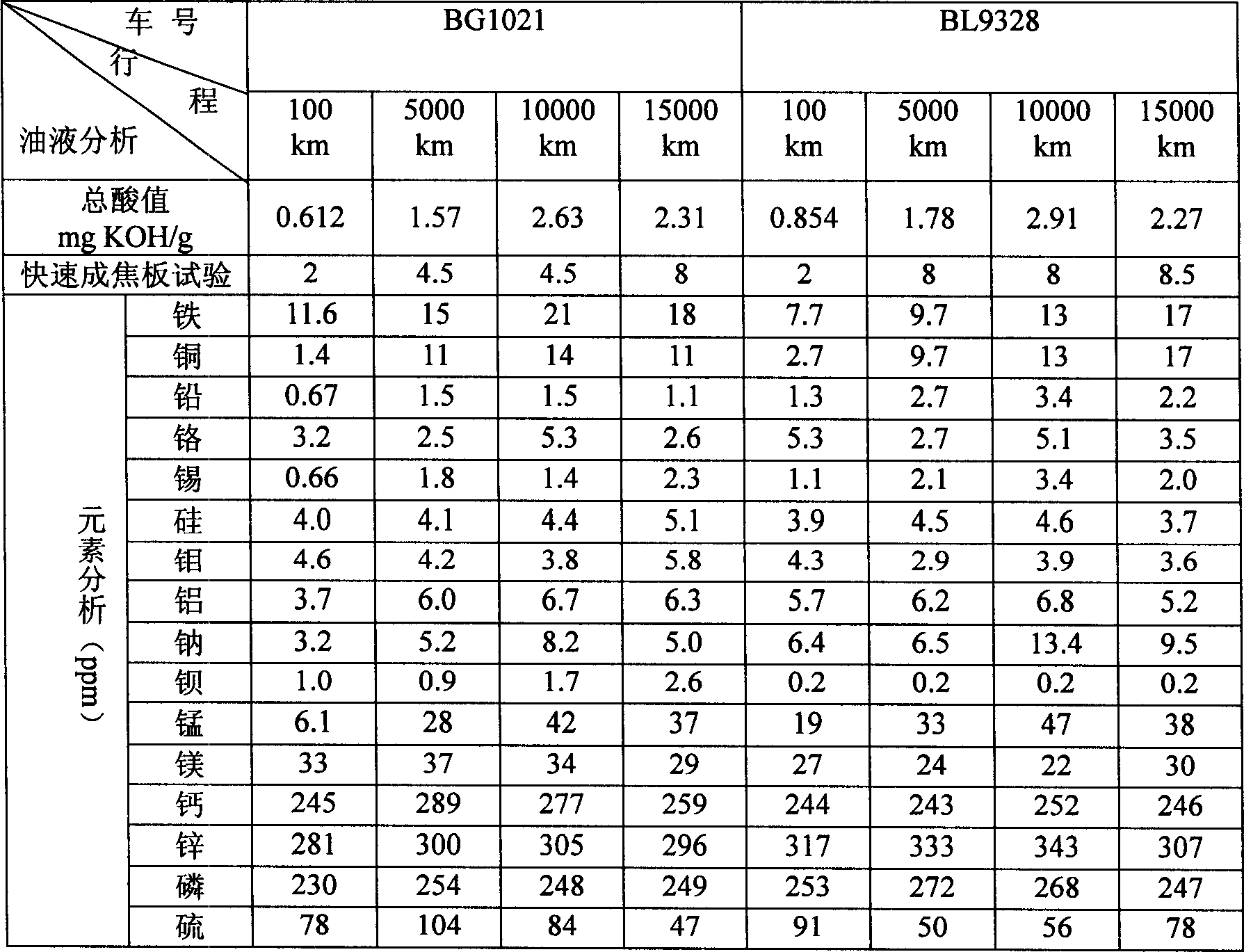

[0017] In the above base oil, based on the amount of base oil, first add ashless detergent and dispersant T-154 (polyisobutenyl succinimide) with a total amount of 7.5%, overbased calcium sulfonate with ash detergent Dispersant, antifoaming agent, fully reconcile, then add 2% nanometer fluorinated graphite anti-wear agent and 0.5% alkyl diphenylamine antioxidant to the above oil sample respectively, fully reconcile, and prepare engine oil containing phosphorus-free compounding agent . The above-mentioned environmentally friendly engine oil was added to the engines of two new Santana cars (BG1021 and BL9328 respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com