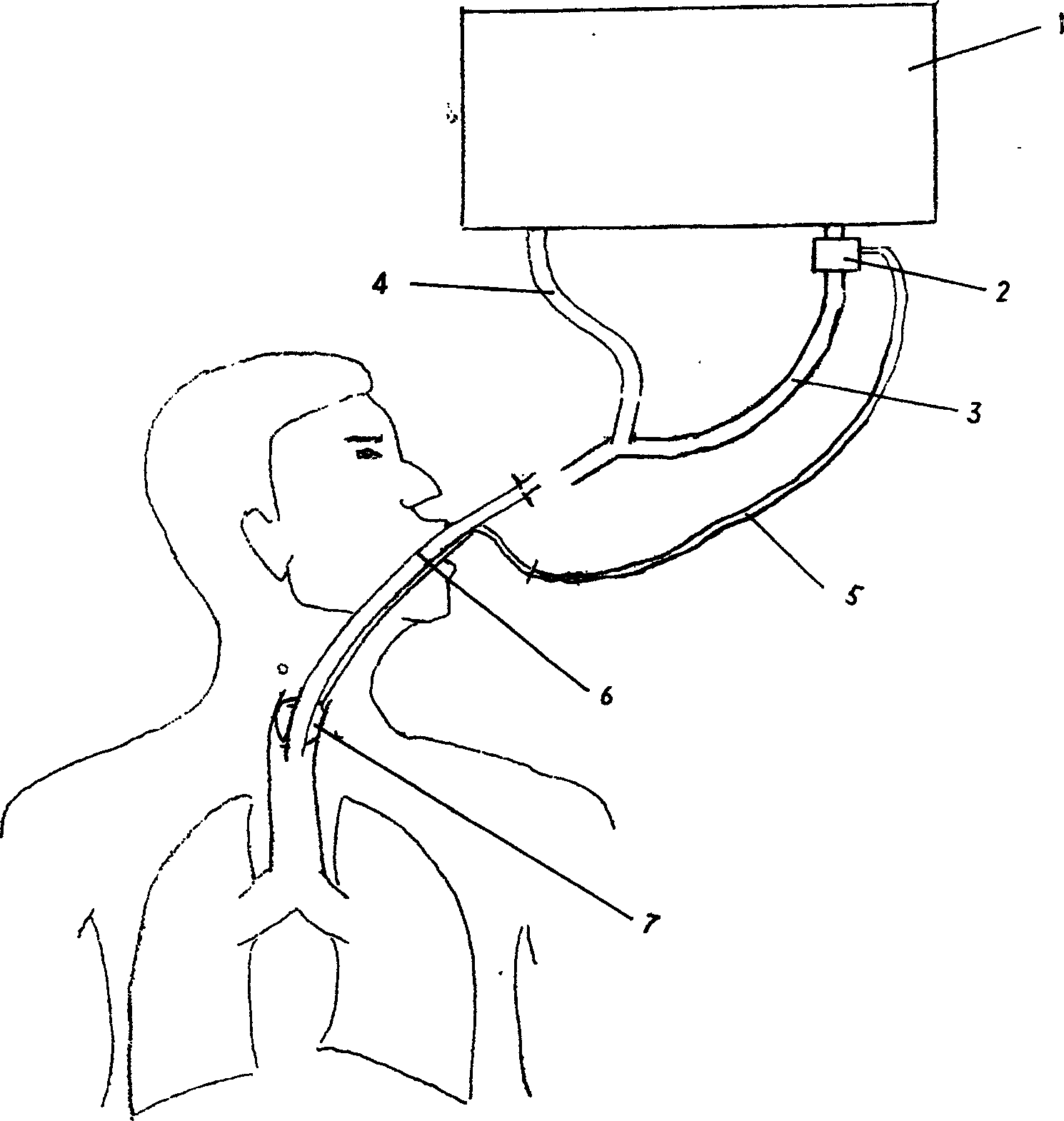

Cannula Automatic aeration unit for air bag of intubation

An automatic inflator and self-inflating technology, applied in the field of medical devices, can solve the problems of inconvenient operation and management, tissue necrosis, massive bleeding, etc., and achieve the effect of convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

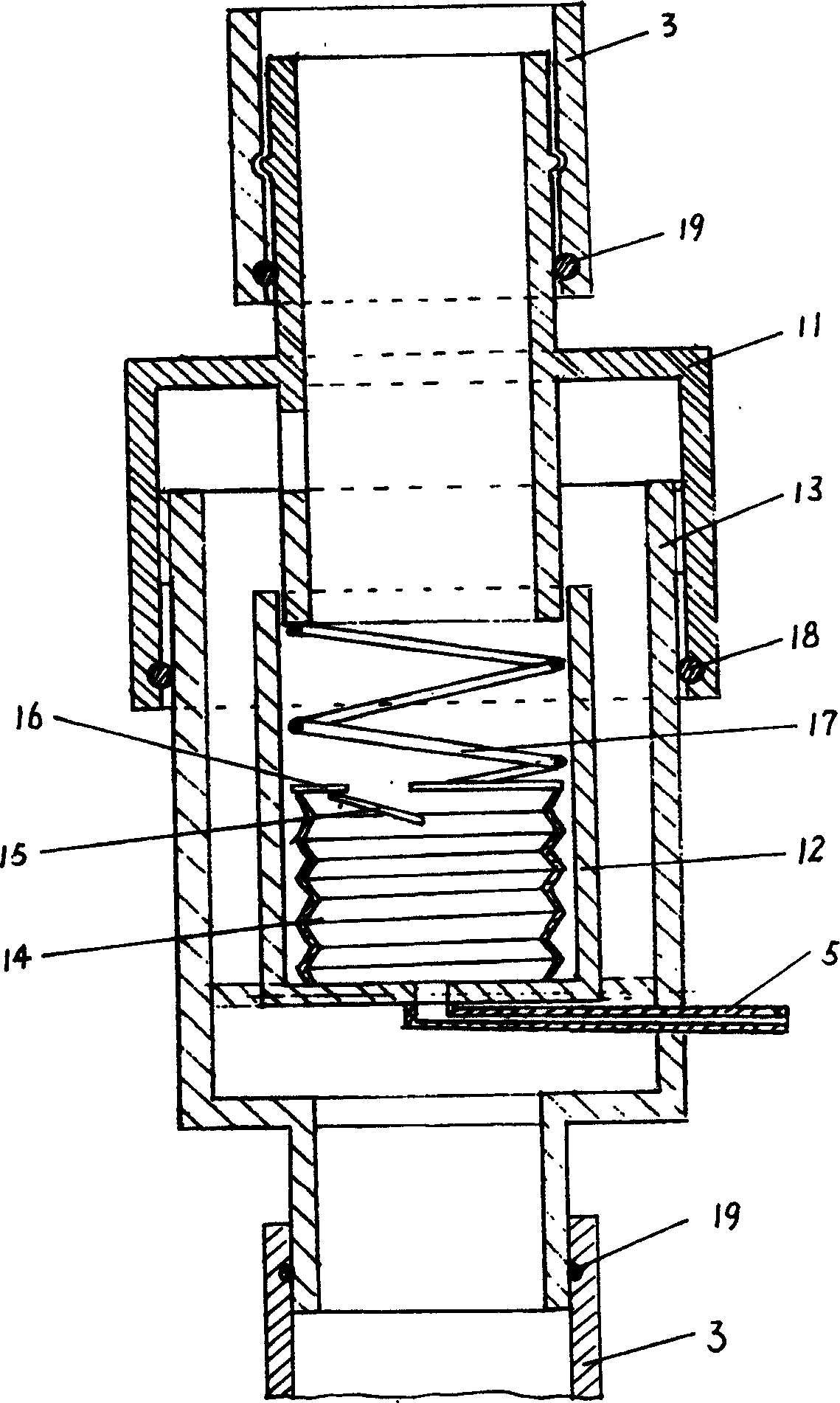

Embodiment 1

[0016] Embodiment one: if figure 2 As shown, the automatic inflation device 2 of the present invention includes an outer sleeve 11 and an inner sleeve 13, the inlet of one end of the outer sleeve 11 communicates with the upper section of the air supply pipe 3, and the other end is separately provided with an inner tube and an outer tube, wherein the inner wall of the outer tube is processed There is an internal thread, which can be screwed with the correspondingly processed external thread on the outer wall of the upper end of the inner sleeve 13 to form a connection relationship; An outlet is processed on the side of the inner tube, which communicates with the inner cavity of the inner casing 13, and communicates with the lower section of the air supply pipe 3 through the inner cavity to form an air supply channel. The inner cavity of the inner casing 13 is provided with an inner cylinder 12 communicating with the inner cavity of the inner tube of the outer casing 11. The in...

Embodiment 2

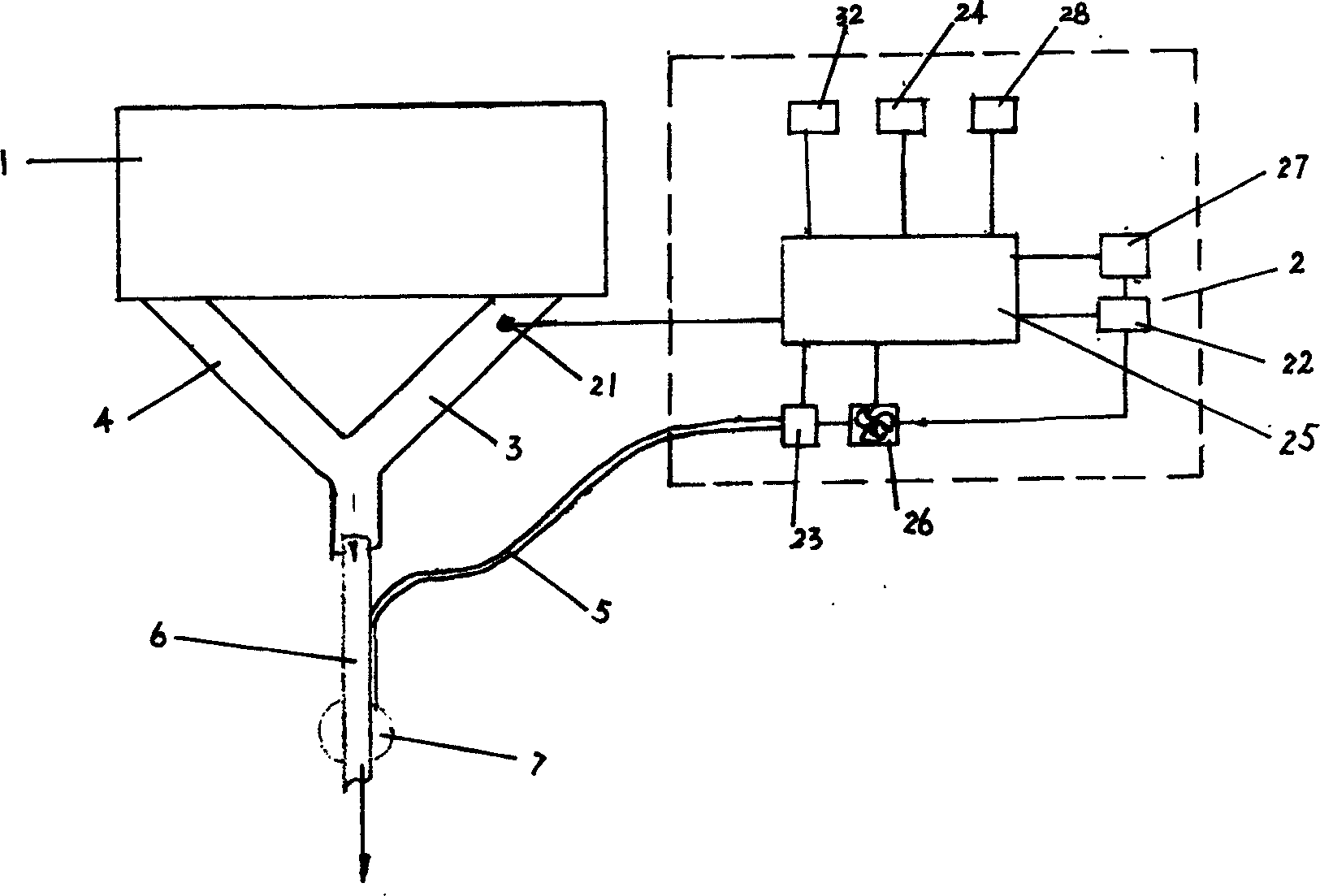

[0021] Such as image 3 As shown, the present embodiment includes a pressure sensor 21, a servo motor 22, an air pump 26 and a frequency conversion circuit 25. The pressure sensor 21 is arranged in the air supply pipe 3 and is connected to the input end of the frequency conversion circuit 25, and the output terminal of the frequency conversion circuit 25 is connected to the servo motor. 22. The air pump 26 is connected with the servo motor 22 and communicated with the balloon catheter 5 at the same time. The pressure sensor 21 can detect pressure changes in the trachea, and input different voltage signals according to the pressure. The greater the pressure, the higher the input voltage, and the pressure and voltage are linearly proportional. Described frequency conversion circuit 25 is the conventional circuit of prior art, and it can convert the signal that pressure sensor 21 measures into frequency signal, control the rotating speed of servomotor 22, the rotation of air pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com