Process for treating waste water of nitrobenzene, 2,4-dinitrophenol, p-nitro-chlorebenzene

A technology of p-nitrochlorobenzene and dinitrophenol, which is applied to nitrobenzene and 2, can solve the problems of low investment, low operating cost, and simple process flow, and achieve small footprint, convenient management, and shortened migration path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

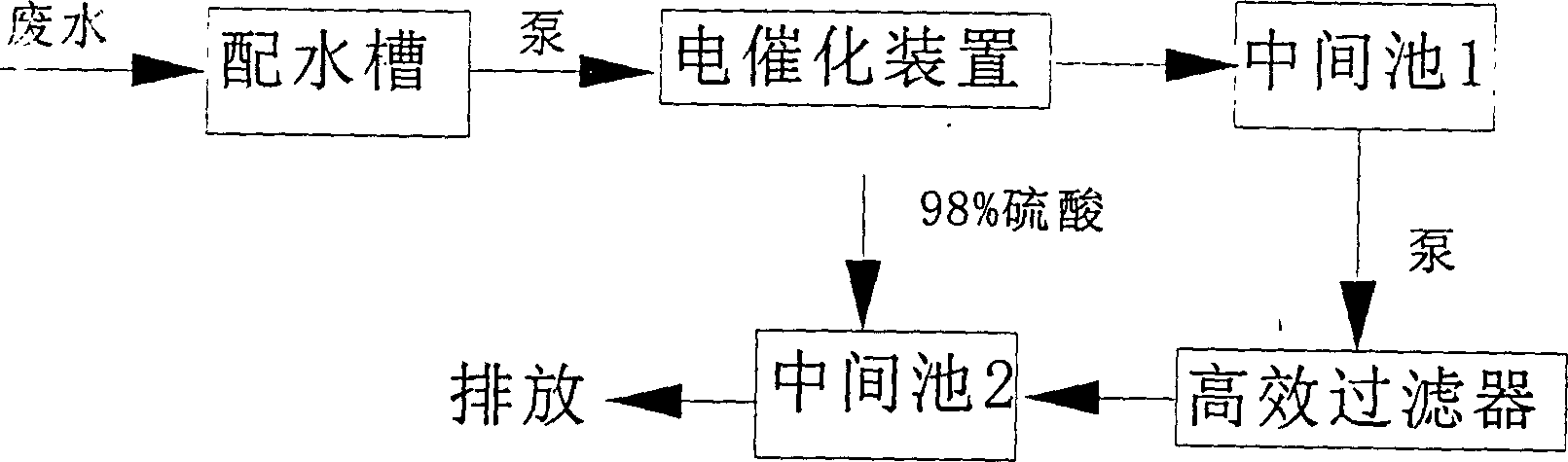

[0016] As can be seen from accompanying drawing 1, the specific implementation method of the inventive method is: the alkaline nitrobenzene production waste water in the distribution tank 1 or the neutral waste water after adjusting the pH value to 7-8 through 98% sulfuric acid pump into activated carbon Particle swarm electrocatalysis device 2, control the influent flow rate to 200-1000l / h, the residence time of wastewater to 20-60min, the operating voltage of the device to 20-50v, the current to 10-30A, the effluent is buffered through the intermediate pool 3 and passed through the microporous filter 4 After filtering, it enters the intermediate pool 5 and uses 98% sulfuric acid to adjust the pH value, and the tail water reaches the first-class discharge standard in Table 4 of the national GB8978-1996 "Comprehensive Wastewater Discharge Standard".

[0017] For neutral waste water, the intermediate pool 5 in the above flow chart can be omitted.

[0018] Table 1 and Table 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com