Working process of tow-to-yarn direct spinning of ramie

A processing method and drafting technology, applied in spinning machines, yarns, drafting equipment, etc., can solve the problems of influence, processing process and product quality, and achieve the reduction of ultra-long fiber content, less fiber damage, and hemp grains. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

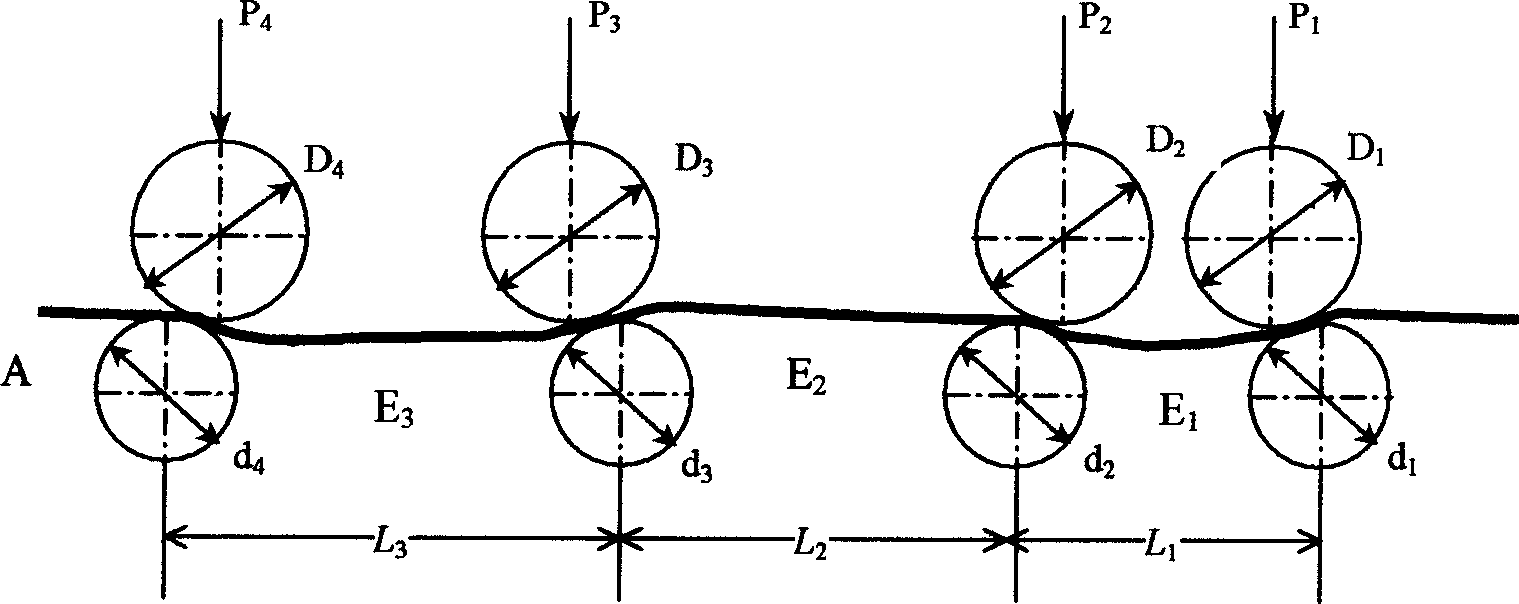

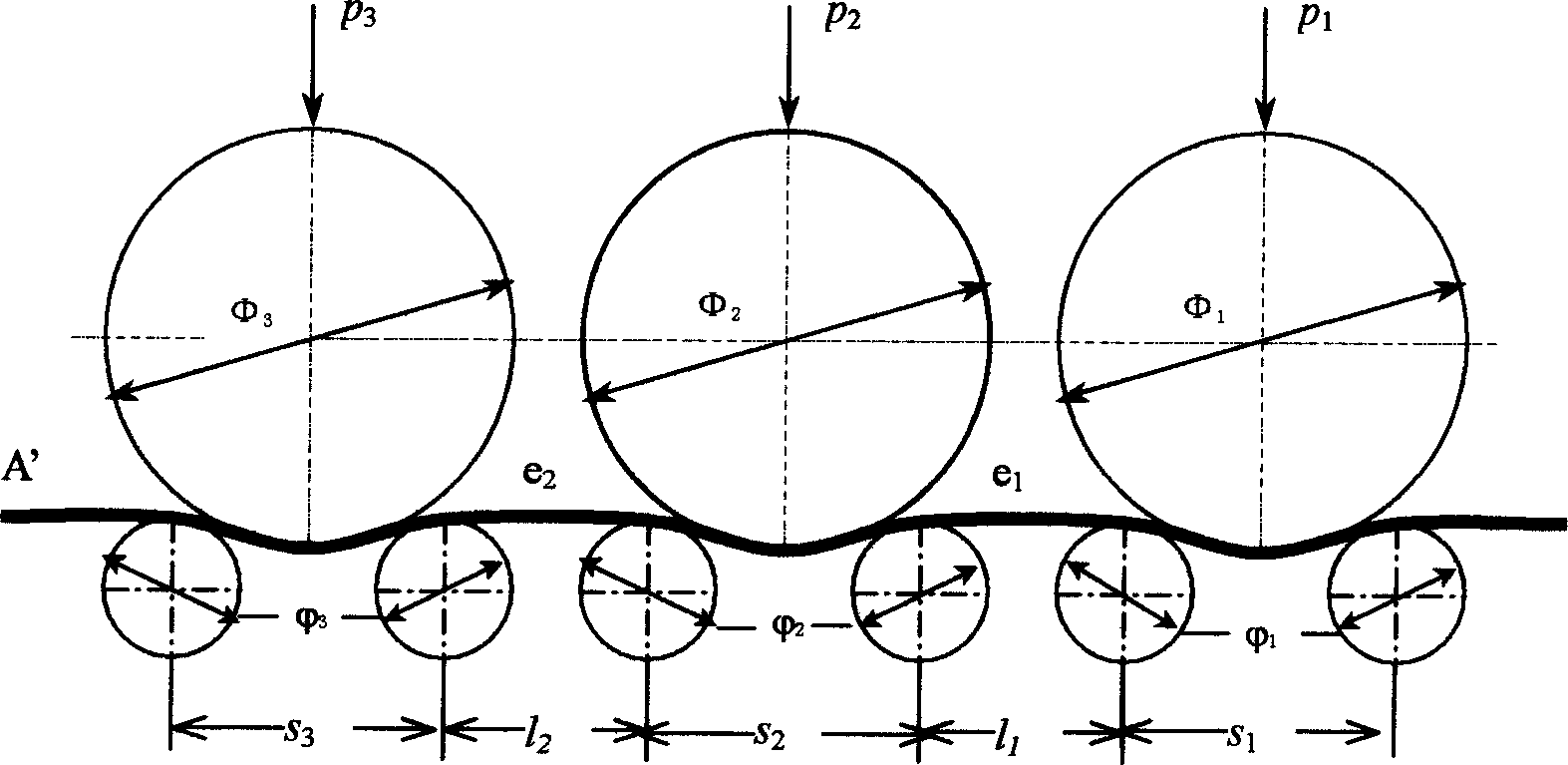

Method used

Image

Examples

Embodiment

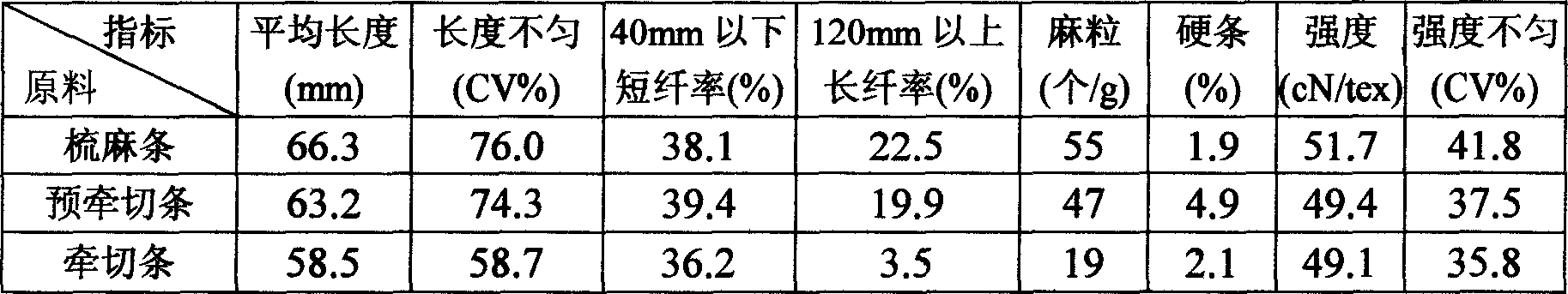

[0035] The ramie refined hemp produced in Hunan is adopted, and its properties are shown in Table 1:

[0036] average length

[0037] After adopting the stretch-cut spinning technique of the present invention to above-mentioned lean hemp raw material to process, the quality performance index of its semi-finished product and finished product is as shown in table 2 and table 3:

[0038] Table 2 Comparison of the quality indicators of stretch-cut strips, pre-stretch-cut strips and carded linen strips (stretch-cut distance is 100mm)

[0039]

[0040] As can be seen from Table 2, the length uniformity of the fibers after stretch cutting is significantly improved, especially the content of ultra-long fibers above 120mm is significantly reduced, and the hemp grains in the fiber strips are greatly reduced than those in the carded hemp strips, and the doubling (hard strips) ) increased slightly; although the strength decreased, the uneven strength was improved because the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com