Mineralized fibroin material and preparation method

A technology of silk protein and protein, applied in medical science, prosthesis, etc., can solve problems such as high cost, safety issues, complex collagen purification process, etc., and achieve good biocompatibility and bioactivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

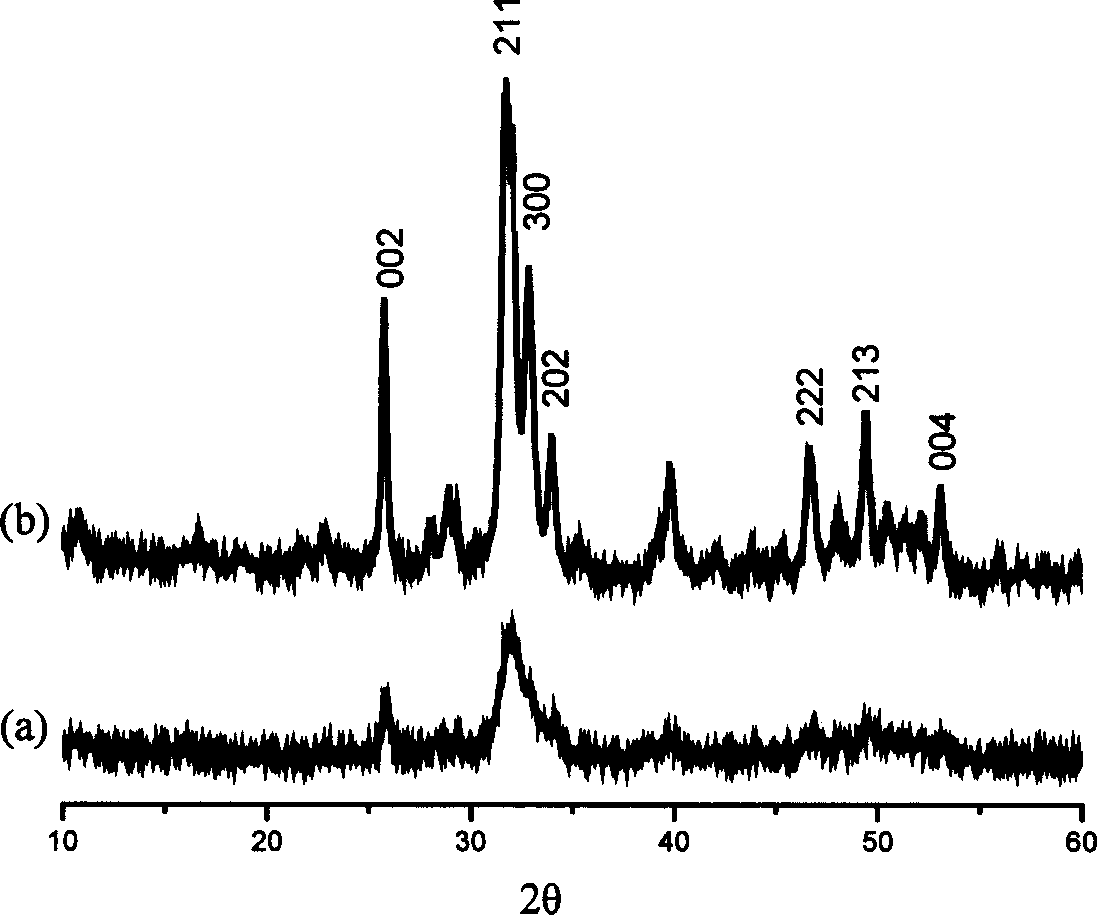

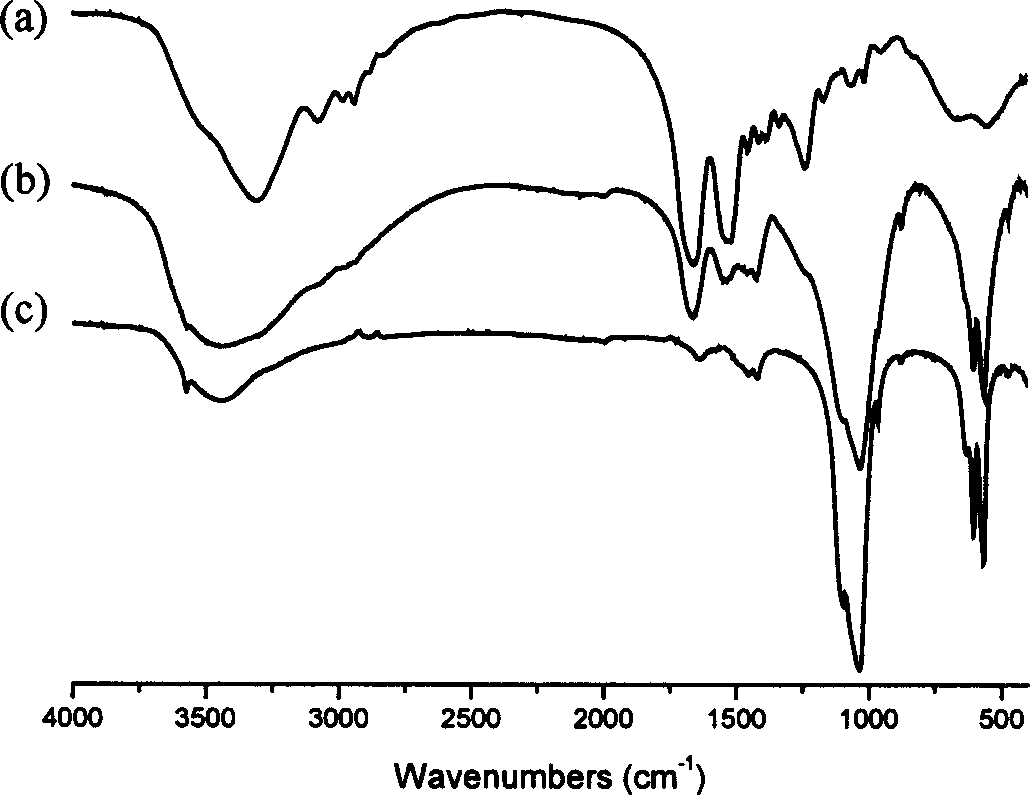

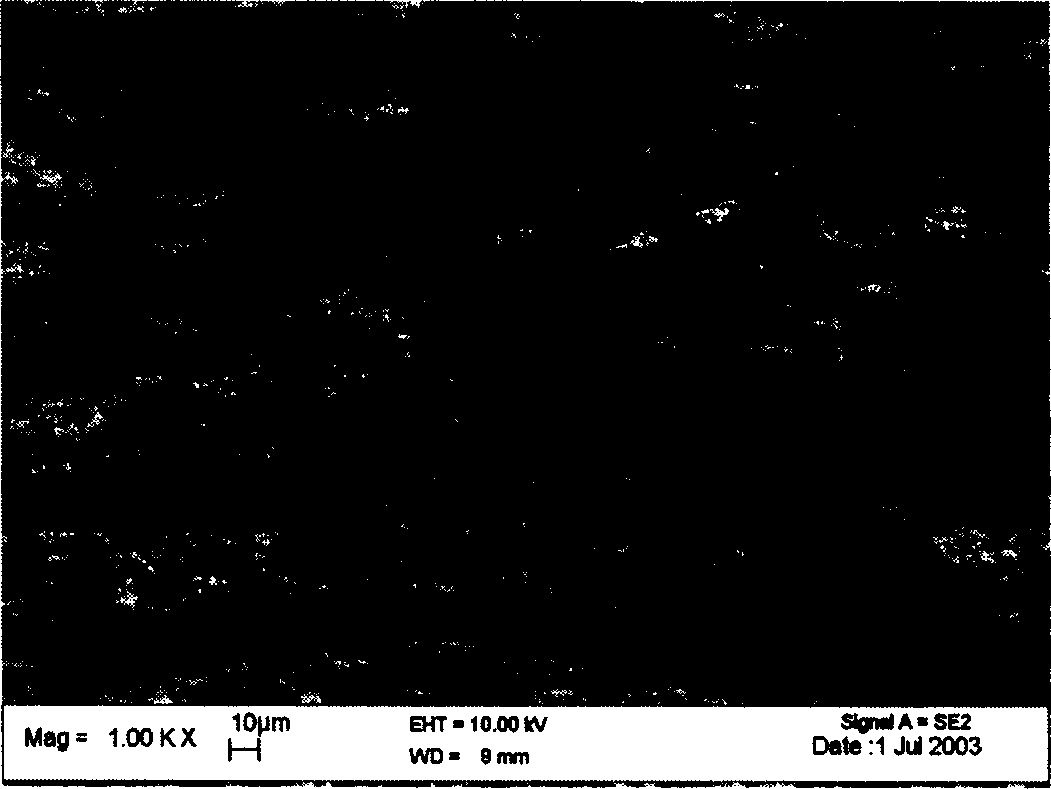

[0027] The preparation method of the mineralized silk protein material proposed by the present invention mainly comprises the following steps:

[0028] (1) Add a solution containing calcium ions dropwise in the silk protein solution, so that the mass percent concentration of silk protein in the solution is finally 0.3%-20%, and the molar concentration of calcium ions is finally 0.01-2mol / L. need constant stirring;

[0029] (2) Slowly add the aqueous solution containing phosphate ion while stirring in the solution of the above-mentioned first step, the mol ratio of the amount of phosphate ion added and the amount of calcium ion added is Ca: P=1~2:1 ;

[0030] (3) Slowly adjust the pH value to 7.4~13 while stirring in the solution of the above-mentioned second step,

[0031] (4) Stir the solution and let it stand. After the precipitate and supernatant are separated, remove the supernatant, centrifuge to separate the precipitate, wash repeatedly with deionized water to remove s...

Embodiment 1

[0033] 1) Add dropwise 500ml of Ca(OH) with a concentration of 0.25mol / L in the 500ml silk protein solution with a concentration of 0.9%. 2 After solution, continue to slowly add NaH with a concentration of 0.25mol / L 2 PO 4 Solution 300ml, mix evenly with a magnetic stirrer while adding dropwise.

[0034] 2) Stir the above system, let it stand, remove the supernatant, centrifuge to separate the precipitate, wash it repeatedly with deionized water to remove the salt and reach neutrality, put it into a lyophilizer to freeze dry, and then grind the dried product A dry powder was prepared.

Embodiment 2

[0036] 1) Add 25ml of CaCl with a concentration of 0.2mol / L to the 450ml silk protein solution with a concentration of 33%. 2 After the solution, continue to slowly drop Na with a concentration of 0.2mol / L 2 HPO 4 Solution 25ml, mix evenly with a magnetic stirrer while adding dropwise.

[0037] 2) Slowly add NaOH solution dropwise to the solution in the first step above while stirring until the pH value is stable at 7.4.

[0038] 3) Stir the above system, let it stand, remove the supernatant, centrifuge to separate the precipitate, wash it repeatedly with deionized water to remove the salt and reach neutrality, put it into a freeze dryer to freeze dry, and then grind the dried product A dry powder was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com