Product of slow releasing gas from addition product of fumaric acid as well as preparing method and application

A technology of fumaric acid and adducts, applied in chemical instruments and methods, transportation and packaging, and other chemical processes, etc., can solve problems such as ups and downs, continuous motion, toys that cannot sink into water, and slow reactions. , to achieve the effect of simple manufacturing equipment, increased strength, and large benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take by weighing raw material (unit: gram) by following weight ratio:

[0042] Fumaric acid 30, sodium carboxymethyl cellulose 5, baking soda 55, polyethylene glycol 5 (m is 3000), magnesium oxide 2, and the balance is essence. The production method is as follows:

[0043] (1). Mix baking soda, magnesium oxide, and essence according to the ratio, and bake at a constant temperature in a thermostat at 140°C for 5 hours;

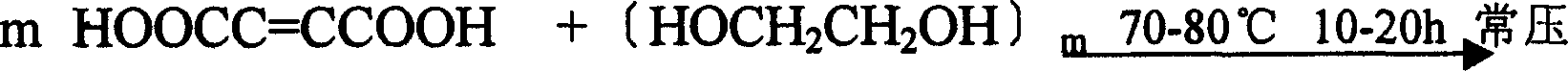

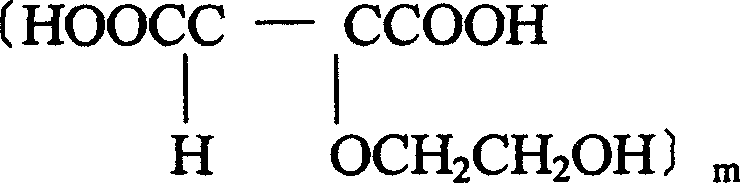

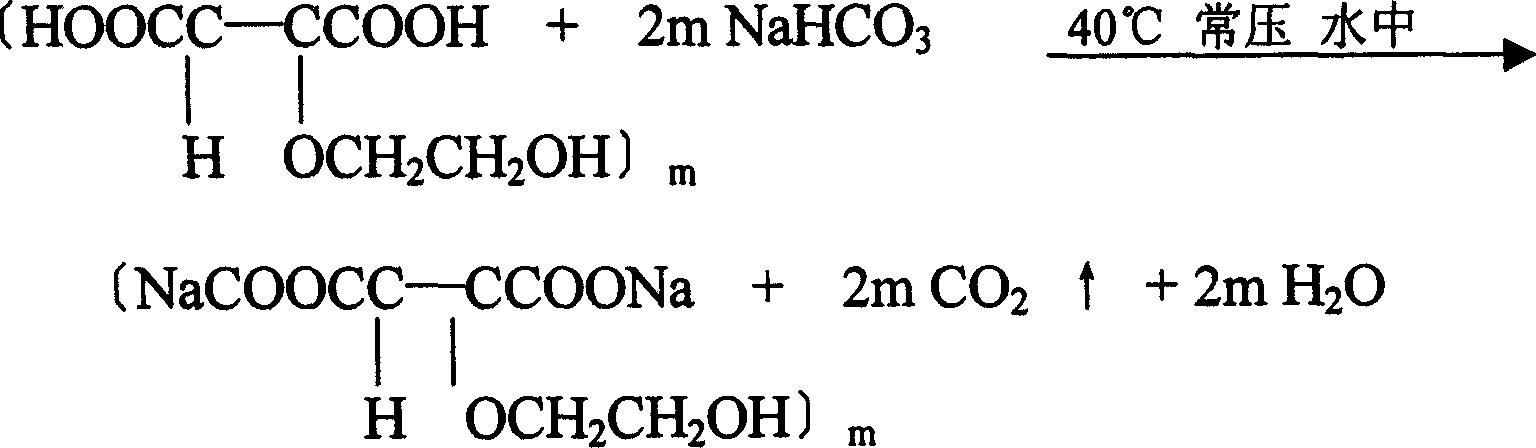

[0044] (2). Fumaric acid and polyethylene glycol (PEG) were reacted for 12 hours at 80° C. under normal pressure to produce an adduct of fumaric acid and polyethylene glycol (PEG);

[0045] (3). The adduct of fumaric acid and polyethylene glycol (PEG) and sodium carboxymethylcellulose are added to the mixed material obtained in step (1), and uniformly mixed;

[0046] (4). The mixed material is molded into a spherical product under the conditions of 25° C. and humidity of 60%.

Embodiment 2

[0048] Take by weighing raw material (unit: gram) by following weight ratio:

[0049] Fumaric acid 33, sodium carboxymethyl cellulose 4, baking soda 50, polyethylene glycol 10 (m is 4000), magnesium oxide 1, and the balance is essence. The production method is as follows:

[0050] (1). Mix baking soda, magnesium oxide, and essence according to the ratio, and bake in a constant temperature oven at 160°C for 3 hours;

[0051] (2). Reaction of fumaric acid and polyethylene glycol (PEG) at 75°C and normal pressure for 18 hours to produce an adduct of fumaric acid and polyethylene glycol (PEG);

[0052] (3). The adduct of fumaric acid and polyethylene glycol (PEG) and sodium carboxymethylcellulose are added to the mixed material obtained in step (1), and uniformly mixed;

[0053] (4). Forming the mixed material with a tablet machine under the conditions of 30°C and 40% humidity to obtain a sheet-like product of 1.8±0.1g.

Embodiment 3

[0055] Take by weighing raw material (unit: gram) by following weight ratio:

[0056] Fumaric acid 35, carboxymethyl cellulose sodium 3, baking soda 52, polyethylene glycol 7 (m is 4500), magnesium oxide 2, and the balance is essence. The production method is as follows:

[0057] (1). Mix baking soda, magnesium oxide, and essence according to the ratio, and bake in a constant temperature oven at 180°C for 1 hour;

[0058] (2). Reaction of fumaric acid and polyethylene glycol (PEG) at 70°C for 20 hours under normal pressure to produce an adduct of fumaric acid and polyethylene glycol (PEG);

[0059] (3). The adduct of fumaric acid and polyethylene glycol (PEG) and sodium carboxymethylcellulose are added to the mixed material obtained in step (1), and uniformly mixed;

[0060] (4). Forming the mixed material with a tablet machine under the conditions of 38° C. and a humidity of 20% to obtain a sheet product of 1.8±0.1 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com