Optical raster temp senser and its mfg. method

A technology of temperature sensor and optical fiber grating, which is applied in the direction of radiation pyrometry, instruments, scientific instruments, etc., can solve problems such as the influence of temperature measurement, and achieve the effect of solving interactive sensitive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

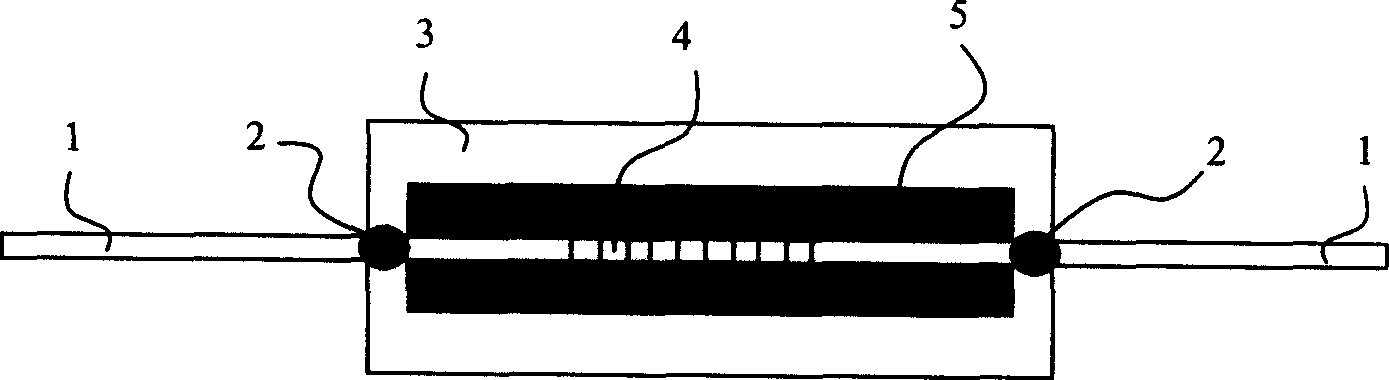

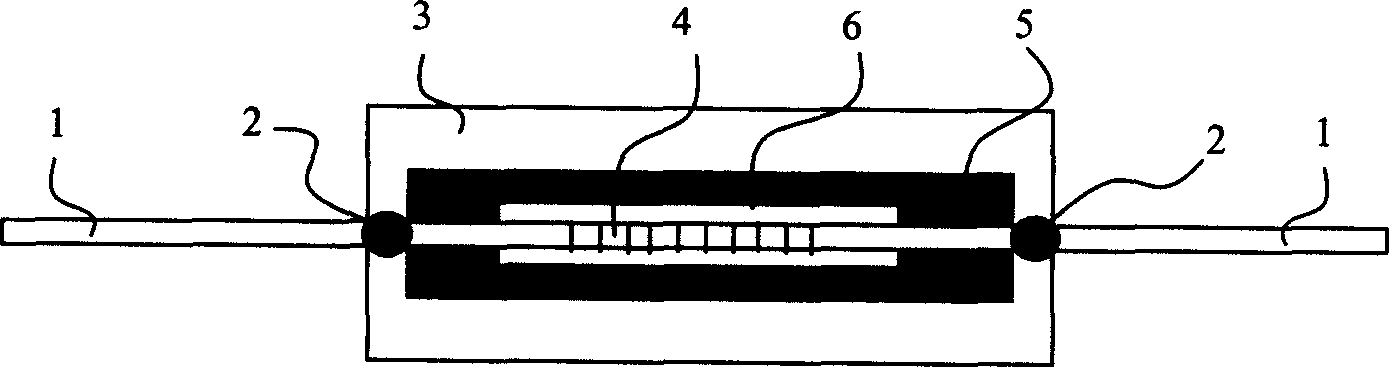

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. as attached figure 1 As shown, the optical fiber coating layer is removed at a section of the optical fiber 1 having photosensitivity and a fiber grating 4 is written using a mask or an interference method. In order to make the fiber grating 4 have good temperature stability and long service life, the fiber grating 4 can be annealed or otherwise aged. Process a metal with good thermal conductivity and mechanical properties, such as stainless steel, into a shape with a cavity inside, and firmly bond the optical fiber lead-out end of the fiber grating 4 to both ends of the metal cavity 3 with an adhesive. The part inside the cavity that includes the fiber grating 4 is not subjected to axial tension, or slightly compressed in the axial direction, so that the optical fiber inside the cavity but not including the fiber grating 4 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com