Preparation material and process for household marsh gas generator

A technology of biogas generator and polypropylene, applied in gas production bioreactors, waste fuels, etc., can solve the problems of long construction period, low production efficiency, leakage, etc., and achieve excellent thermal insulation performance, rapid production, and high biogas production rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

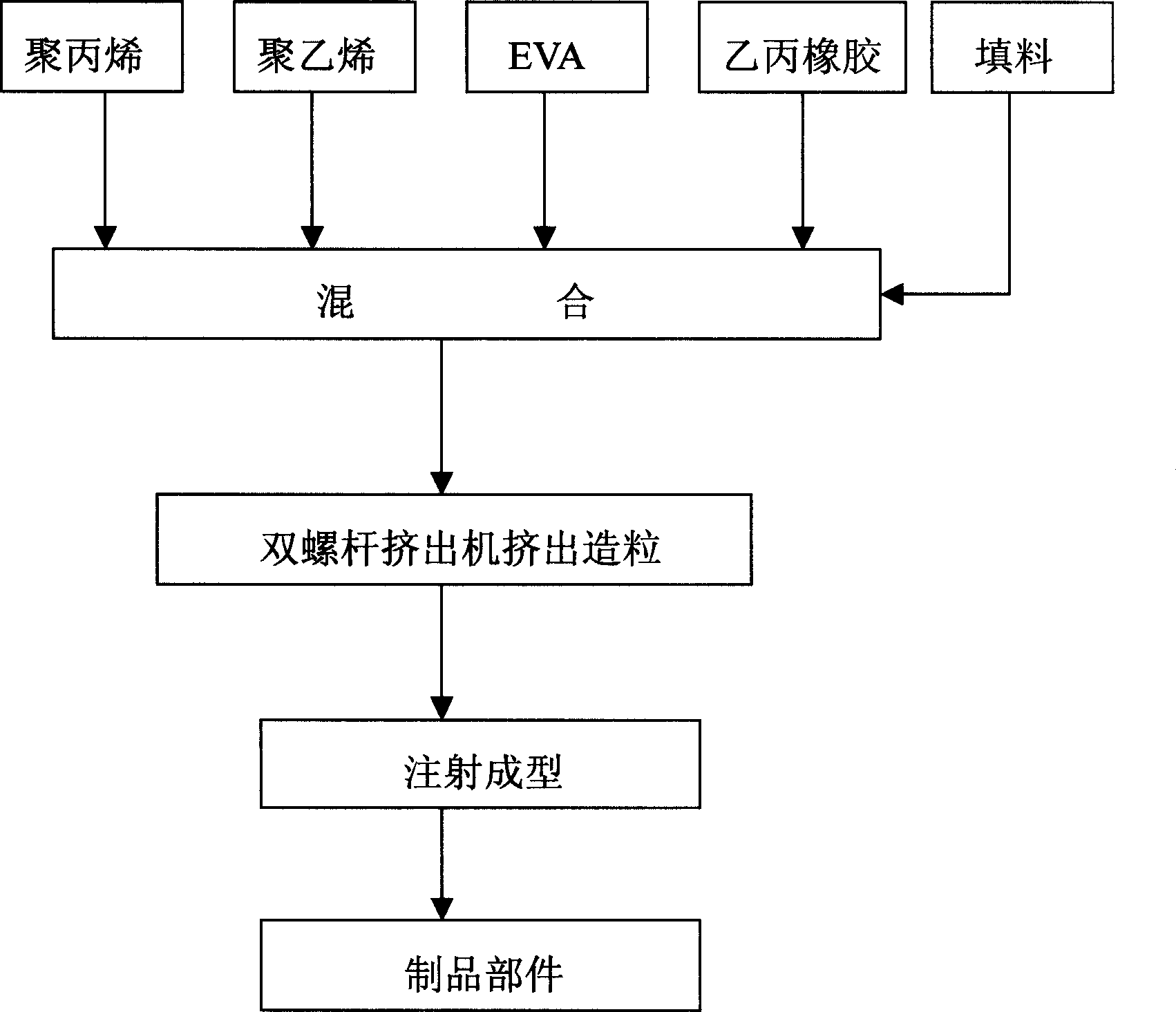

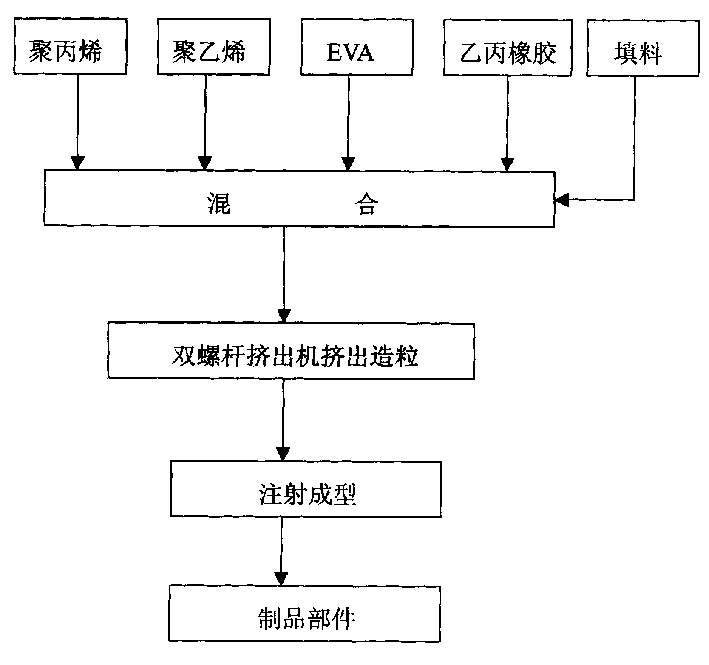

Image

Examples

Embodiment

[0010] Example: Preparation of Modified Polypropylene and Its Injection Molding

[0011] Weigh 100 parts of polypropylene by weight, 15 parts of ultra-high molecular weight polyethylene, 25 parts of EVA, 15 parts of EPDM rubber (granular), 45 parts of superfine calcium carbonate, and 25 parts of superfine talcum powder. Add to LDH mixer and mix for 20 minutes. Add the mixed material into the feeding hopper of the twin-screw extruder. The temperature of the extruder is controlled in sections. The temperature of each section from the feeding section to the extrusion section is as follows: 150~160°C, 165~170°C, 170°C ~180℃, 180~190℃, 195~205℃. After extrusion, it is drawn and cooled in a water tank, and then pelletized by a pelletizer for injection molding.

[0012] During injection molding, the temperature of the barrel is controlled in sections from the feeding section to the nozzle. The temperature of each section is as follows: 155°C, 160-165°C, 170-185°C, the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com