Ageing testing system

A burn-in test and flat-panel display technology, applied in the field of inspection systems, can solve the problems of inability to increase production capacity, insufficient driving ability, and insufficient driving ability of signal sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

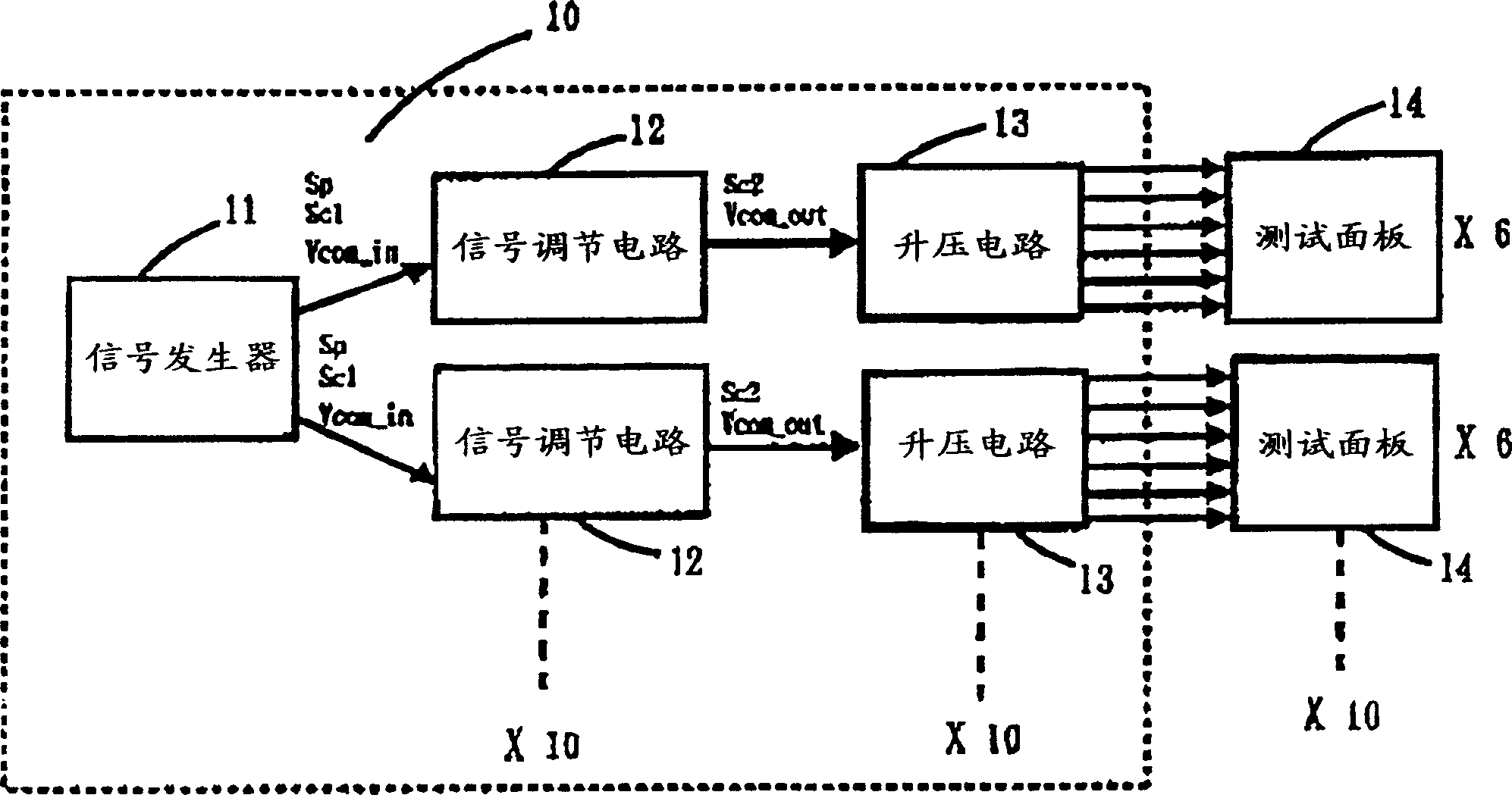

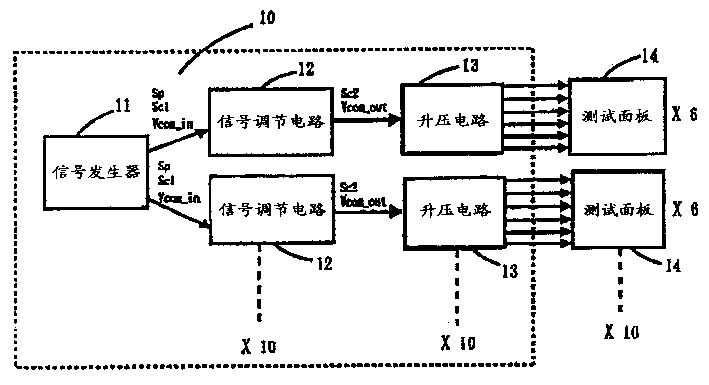

[0031] see figure 1 , which is a schematic circuit block diagram of the burn-in testing system of the preferred embodiment of the present invention. this invention figure 1 The illustrated embodiment is illustrated by driving 60 flat display panels, but based on the same principle and application, users can design their own system and adjust the number of flat display panels according to requirements.

[0032] Such as figure 1 As shown, the aging test system 10 of the present invention can be electrically connected with 60 flat display panels 14 to perform aging detection on these flat display panels 14 . The burn-in test system 10 of the present invention is mainly composed of a signal generator 11, at least one signal conditioning circuit 12 and at least one boost circuit 13, wherein the burn-in test system 10 and the flat display panel 14 are arranged in an environmental test chamber (not shown) show).

[0033] In the above-mentioned embodiment, the signal generator 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com