Mixed ferment process of yellow rice wine and distiller' grain

A technology for mixed fermentation and rice distiller's grains, which is applied in the field of mixed fermentation of rice wine with grains, can solve the problems such as insufficient utilization and waste of rice distiller's grains starch, and achieves the effects of being beneficial to reproduction, reducing starch loss and saving food.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

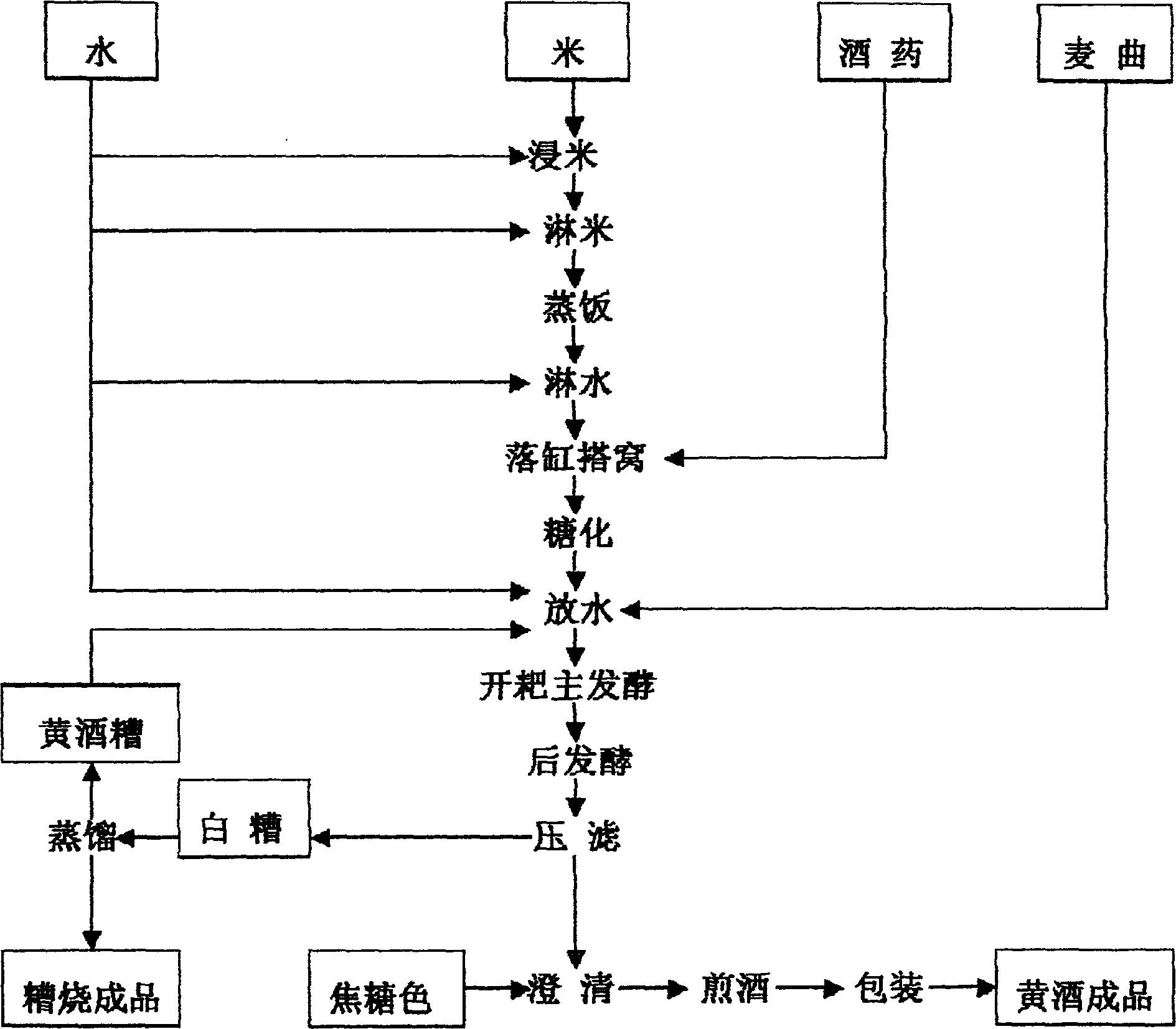

[0017] Example 1: Put 5,000 kilograms of rice into an appropriate amount of water to soak the rice—drench the rice—steam the rice—drench the water—fall into the vat and build a nest. Wheat koji—open rake, main fermentation—post-fermentation—press filtration—clarification, add appropriate amount of caramel color during clarification—decoction—packing—finished rice wine, and at the same time put the white grains produced after pressure filtration into big bran powder, big bran powder The proportion is 6% of the amount of white grains. Distiller’s distiller’s grains are made into burnt products, and the final product is distiller’s grains. The temperature of distiller’s grains should be controlled at 28°C. When rice wine is reproduced, only 4,500 kg of rice needs to be put in. When water is released, 1,300 kg of distiller’s grains and wheat koji are weighed. Mix well with the rice and water in the tank, and mix and ferment. The amount of wheat koji is still the amount required in...

Embodiment 2

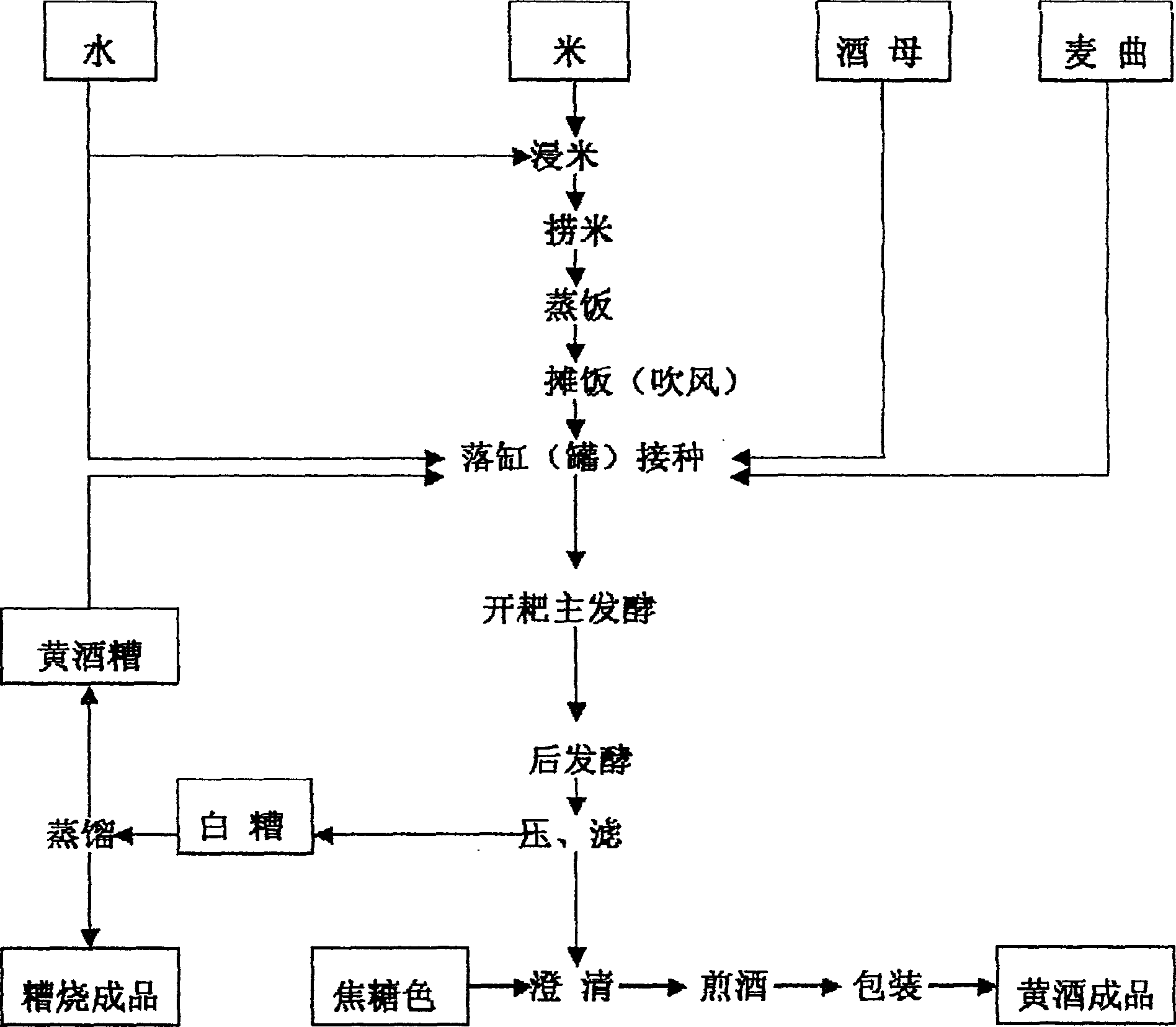

[0018] Example 2: Put 5000 kilograms of rice into appropriate amount of water for rice soaking-fishing rice-steaming rice-spreading rice-fall tank inoculation, put appropriate amount of distiller's mother and wheat koji in the tank inoculation-open rake main fermentation-post-fermentation-press Filtration—clarification, when clarifying, add appropriate amount of caramel color—decoction—packing—finished rice wine, and at the same time put the white grains produced after pressure filtration into the grain husk, the proportion of the grain husk is 5% of the white grains, and it is made by distillation Distiller's grains are burned into finished products, and the temperature of distiller's grains should be controlled at 35°C. When rice wine is re-produced, only 4600 kg of rice is needed. Mix well with the rice and water in the tank, and mix and ferment. The amount of wheat koji is still the amount required in the original traditional production, and the rest of the operations remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com