Intermediate frequency inductive carburizing furnace

A carburizing furnace and intermediate frequency technology, which is applied in the field of intermediate frequency induction carburizing furnace, can solve the problems of short service life, high production cost, and low work efficiency of the background technology, and achieve reduced furnace repair work, high work efficiency, and low maintenance cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

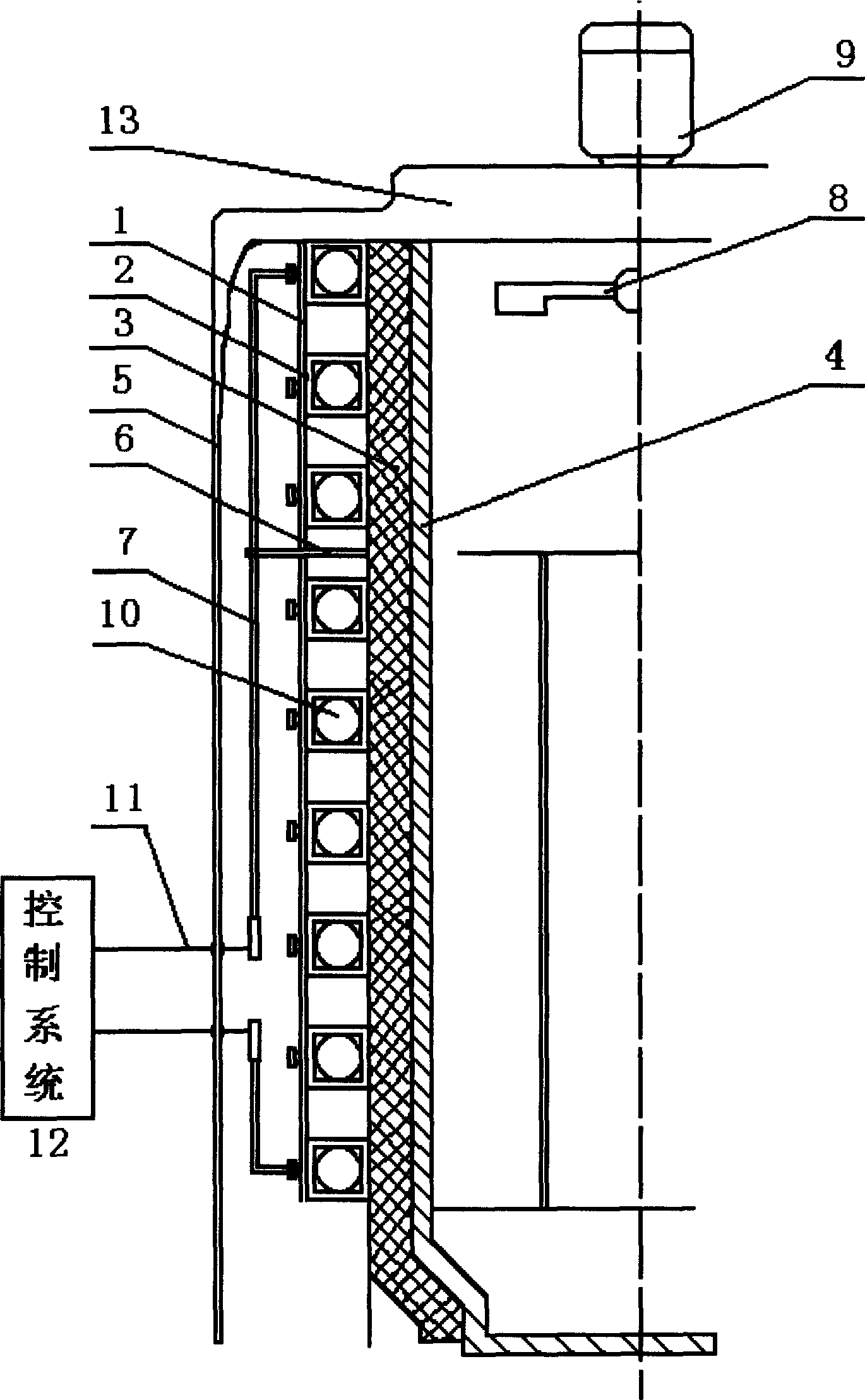

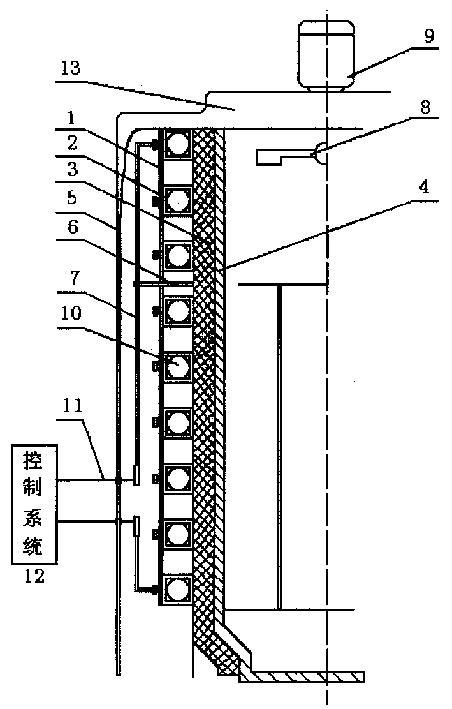

[0031] Referring to the accompanying drawings, the present invention retains the carburizing device 13, the muffle tank 4, the airflow stirring fan 8, the motor 9 and the carburizing furnace shell 5 of the prior art. The outside of the muffle tank 4 is provided with an insulation layer 3 , and the outside of the insulation layer 3 is provided with an inductor 2 . The outside of the muffle tank 4 is provided with a temperature detection head 6 in contact with it, and the detection head 6 is connected to the control system 12 through an external wire 11 . The sensor 2 is preferably a hollow sensor, and a water circulation pipe 10 connected to an external water circulation system can be arranged in the hollow of the sensor 2, so that the temperature of the sensor 2 itself will not be too high. Specifically, the detection head 6 can be a thermocouple.

[0032] The invention adopts the principle of induction heating, and replaces the traditional heating electric furnace wire and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com