Method for preparing micron spherical mesoporous silicon dioxide

A mesoporous silica, spherical technology, applied in the direction of silicon oxide, etc., can solve the problem of low yield and achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) prepare hydrochloric acid solution, the concentration of hydrochloric acid is 2.0 mol / liter.

[0022] (2) prepare the solution of surfactant, add surfactant in step (1), make the concentration of cetyltrimethylammonium bromide in the mixed solution be 0.05 mole / liter; The concentration of polyvinyl alcohol is 8.0 g / L; the concentration of poly(oxyethylene)-poly(oxypropylene)-poly(oxyethylene) is 3.5×10 -4 mol / liter.

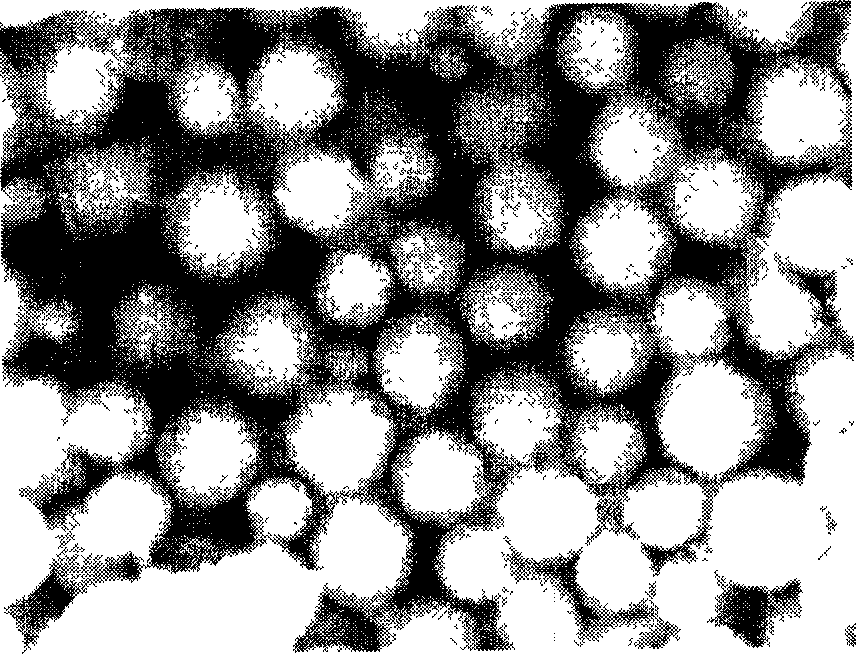

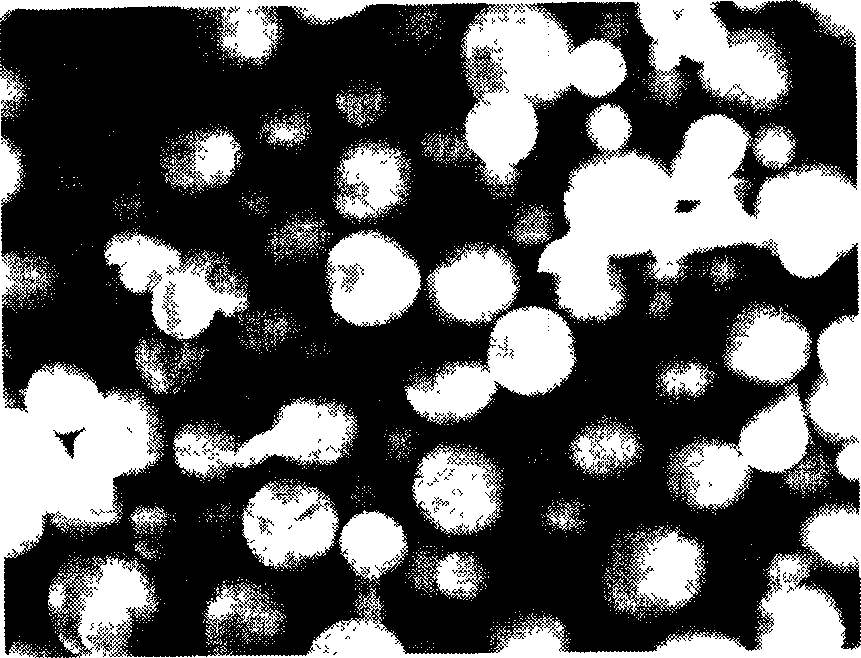

[0023] (3) Ethyl orthosilicate is added to the mixed solution obtained in step (2), so that the concentration of ethyl orthosilicate after mixing is 0.50 mol / liter, continue to stir for 7 minutes, and then stand for a period of time to obtain white The precipitated solution was centrifuged, washed, dried, and calcined at 600°C to obtain mesoporous silica with an average particle size of 1.3 μm and a specific surface area of 860 m 2 / g, the mesopore size is 4.4nm.

Embodiment 2

[0025] (1) prepare nitric acid solution, the concentration of nitric acid is 6.0 mol / liter.

[0026] (2) prepare the solution of surfactant, add surfactant in (1), make the concentration of cetyltrimethylammonium chloride in the solution after mixing and dissolving be 0.040 mole / liter; The concentration of polyvinyl alcohol is 6.0 g / L; the concentration of poly(oxyethylene)-poly(oxypropylene)-poly(oxyethylene) is 6×10 -4 mol / liter.

[0027] (3) Ethyl orthosilicate is added to the mixed solution obtained in step (2), so that the concentration of methyl orthosilicate after mixing is 4.0 mol / liter, continue to stir for 15 minutes, and then stand for a period of time to obtain white The precipitated solution was centrifuged, washed, dried, and calcined at 550°C to obtain mesoporous silica with an average particle size of 2.1 μm and a specific surface area of 920 m 2 / g, the mesopore size is 2.7nm.

Embodiment 3

[0029] With embodiment 1, change the hydrochloric acid in the step (1) into sulfuric acid, other conditions are constant, obtain mesoporous silica, average particle diameter is 3.1 μ m, specific surface area is 1090m 2 / g, the mesopore size is 2.3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mesopore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com