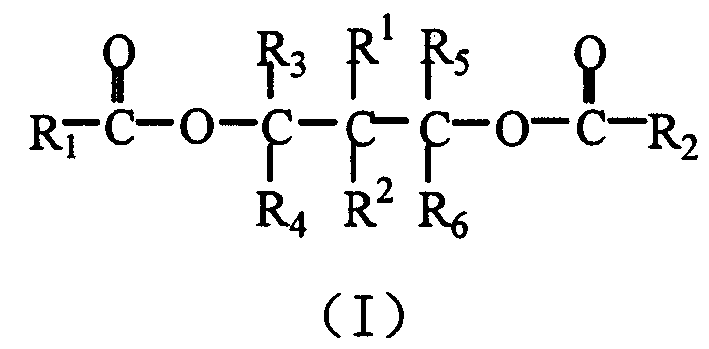

Glycol ester compound for preparing catalyst for olefinic polymerization

A technology of compounds and glycol esters, which is applied in the field of preparation of olefin polymerization catalysts, can solve the problems of unfavorable polymer development, low catalytic activity of catalysts, low isotacticity of polymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of 2,4-pentanediol di(m-chlorobenzoate) ester

[0037] Add 30ml tetrahydrofuran and 0.09mol pyridine to 0.03mol 2,4-pentanediol, add 0.075mol m-chlorobenzoyl chloride under stirring, and heat to reflux for 4h. After cooling, add 20ml of saturated brine, extract with ethyl acetate, anhydrous Na 2 SO 4 Dry and remove solvent. Column chromatography gave 2,4-pentanediol di(m-chlorobenzoate) as a colorless viscous liquid with a yield of 95%.

[0038] 2,4-pentanediol bis(m-chlorobenzoate) ester 1 H NMR (TMS, CDCl 3 , ppm): δ1.3~1.4 (6H, d, methyl H), δ1.9~2.3 (2H, m, methylene H), δ5.2~5.3 (2H, m, methine of ester group group H), δ7.3~8.1 (8H, m, benzene ring H).

Embodiment 2

[0040] Preparation of 2,4-pentanediol di(o-bromobenzoate) ester

[0041] Add 30ml tetrahydrofuran and 0.09mol pyridine to 0.03mol 2,4-pentanediol, add 0.075mol o-bromobenzoyl chloride under stirring, and heat to reflux for 4h. After cooling, add 20ml of saturated brine, extract with ethyl acetate, anhydrous Na 2 SO 4 Dry and remove solvent. Column chromatography gave 2,4-pentanediol di(o-bromobenzoic acid) ester as a colorless liquid with a yield of 90%.

[0042] 2,4-pentanediol bis(o-bromobenzoate) ester 1 H NMR (TMS, CDCl 3 , ppm): δ1.3~1.4 (6H, m, methyl H), δ2.06~2.09 (2H, d, methylene H), δ5.2~5.3 (2H, m, methine of ester group group H), δ7.3~7.9 (8H, m, benzene ring H).

Embodiment 3

[0044] Preparation of 2,4-pentanediol di(p-toluate) ester

[0045] Add 30ml tetrahydrofuran and 0.09mol pyridine to 0.03mol 2,4-pentanediol, add 0.075mol p-toluyl chloride under stirring, and heat to reflux for 4h. After cooling, add 20ml of saturated brine, extract with ethyl acetate, anhydrous Na 2 SO 4 Dry and remove solvent. Column chromatography gave 2,4-pentanediol di(p-toluate) as a colorless liquid with a yield of 90%.

[0046] 2,4-pentanediol di(p-toluate) ester 1 H NMR (TMS, CDCl 3 , ppm): 1.3~1.4 (6H, d, methyl H), 2.0~2.1 (2H, t, methylene H), 2.3~2.4 (6H, m, methylene H), 5.2~5.3 (2H , m, methine H of the ester group, 7.1 to 8.0 (8H, m, benzene ring H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com