Preparation of nano pearls powder

A pearl powder and nano-scale technology, which is applied in the field of preparation of nano-scale pearl powder, can solve the problems of low absorption and utilization efficiency and affect the efficacy of pearl powder, and achieve the effects of improving utilization rate, easy industrial production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

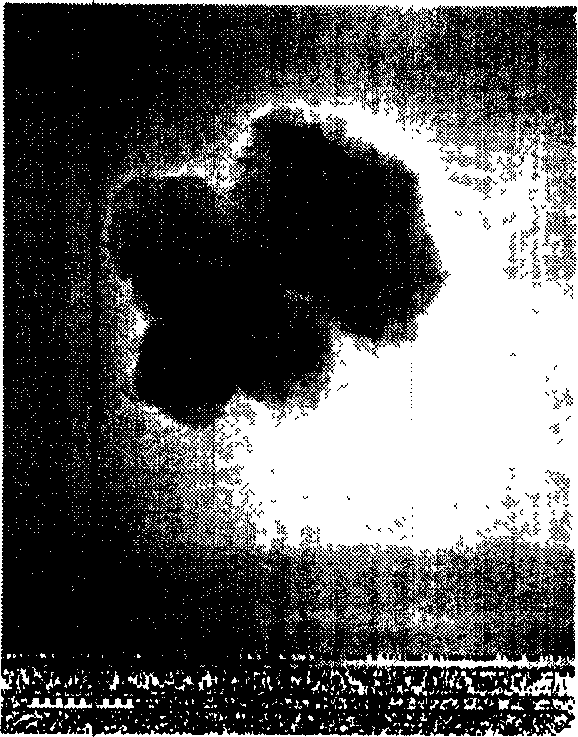

[0018] Wash and dry the pearls with clean water, process them to 300 mesh with high-frequency vibration mill, then mix with deionized water to prepare a 20wt% suspension, set the pressure of the high-pressure homogenizer to 100MPa, add the suspension to To the feeding tank of the high-pressure homogenizer, automatic feeding, the collected and processed suspension is sprayed into a drying room with a temperature of 100°C by means of centrifugal spray drying to obtain pearl powder with a particle size of 50-100nm. Its transmission electron microscope pictures are shown in figure 1 .

Embodiment 2

[0020] After the pearls are washed and dried with clear water, they are processed to 400 mesh by high-frequency vibration mill, and then mixed with deionized water to prepare a 10wt% suspension. The pressure of the high-pressure homogenizer is set to 120MPa, and the suspension is added to To the feeding tank of the high-pressure homogenizer, automatic feeding, the collected and processed suspension is sprayed into a drying room with a temperature of 100°C by means of centrifugal spray drying to obtain pearl powder with a particle size of 50-80nm.

Embodiment 3

[0022] Wash and dry the pearls with clean water, process them to 500 mesh with high-frequency vibration mill, then mix them with deionized water to prepare a 5wt% suspension, set the pressure of the high-pressure homogenizer to 140MPa, add the suspension to To the feeding tank of the high-pressure homogenizer, automatic feeding, the collected and processed suspension is sprayed into a drying room with a temperature of 100°C by means of centrifugal spray drying to obtain pearl powder with a particle size of 50-70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com