Power supply and control system for metal solidifying process

A metal solidification and power supply technology, which is applied in the field of melt solidification device and its control system, can solve the problems of irregular waveform, unstable current amplitude, pulse width and frequency cannot be continuously adjusted and controlled, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

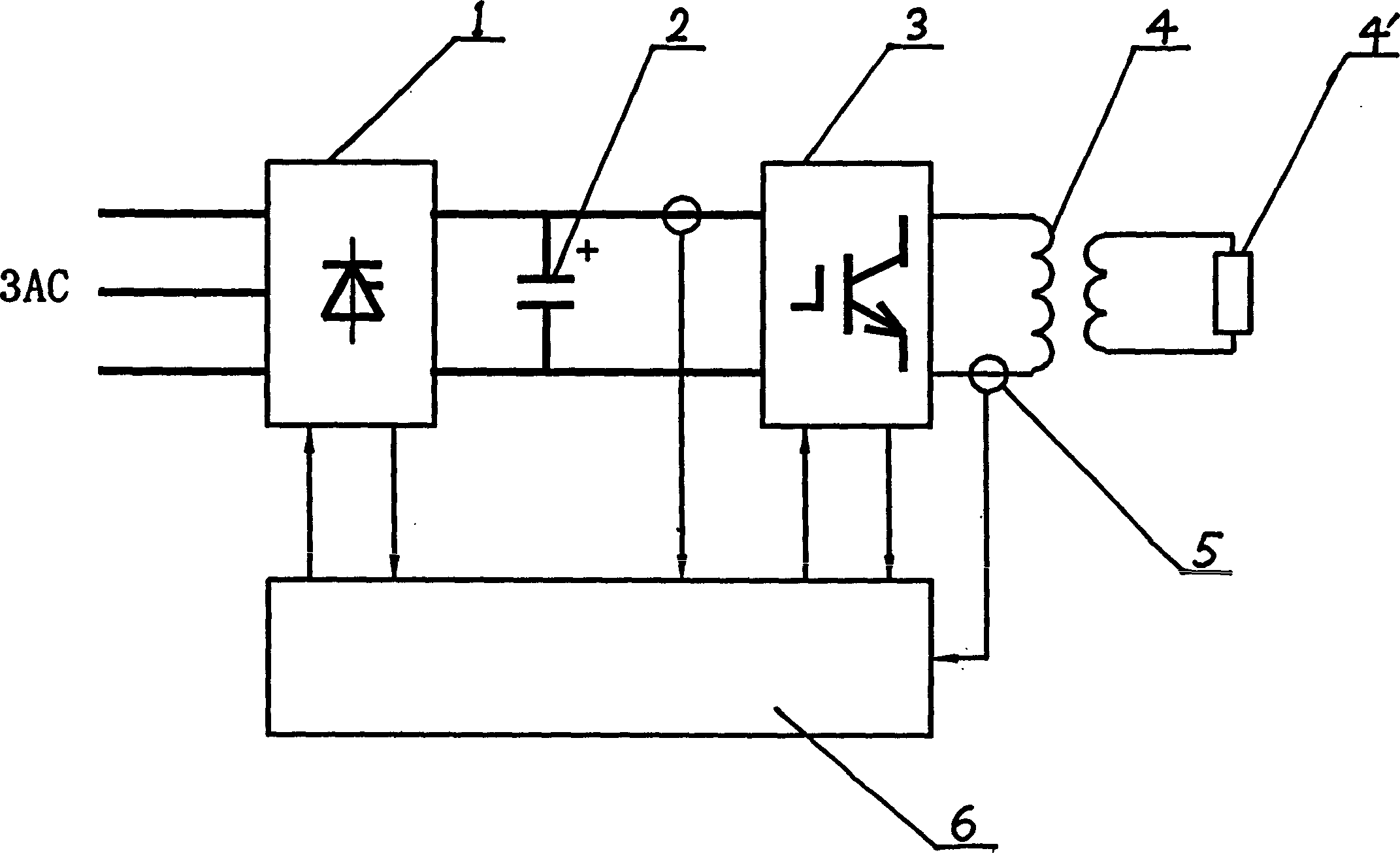

[0010] Such as Figure 1 As shown, the present invention is a power supply and its control system for the metal solidification process. Composed of transformer (4), pulse current detector (5), and computer control unit (6), the three-phase alternating current is converted into a voltage-controllable DC pulsating voltage through a three-phase fully-controlled rectifier bridge circuit (1), and then filtered by DC The device (2) becomes a DC voltage, which becomes a pulse voltage through a single-phase inverter bridge circuit (3), and then becomes a pulse current after passing through a pulse transformer (4) and a load (4′), and is controlled by a pulse current detector (5) The detection is carried out, and the detection amount is fed back to the computer control unit (6) for control. The pulse current detector (5) is a Hall current sensor. The computer control unit (6) takes the embedded single-chip microcomputer PIC16F877 as the core.

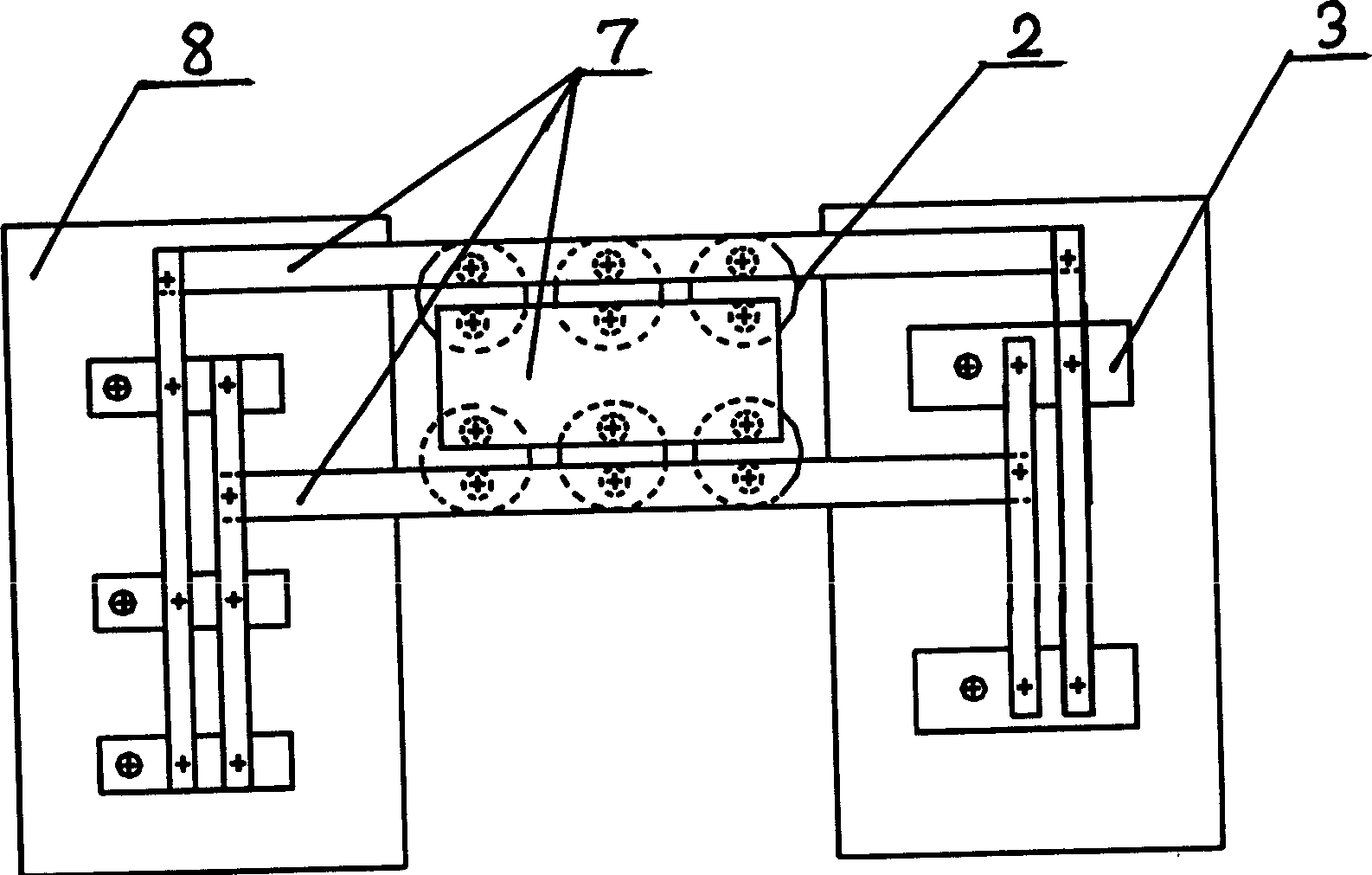

[0011] As shown in Figure 2, the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com