Apparatus for recycling and supplying lubricating oil

A lubricating oil and equipment technology, applied in the field of lubricating oil circulation supply equipment, can solve the problems of shortening the life of the catapult, increasing the waste of lubricating oil, increasing the manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

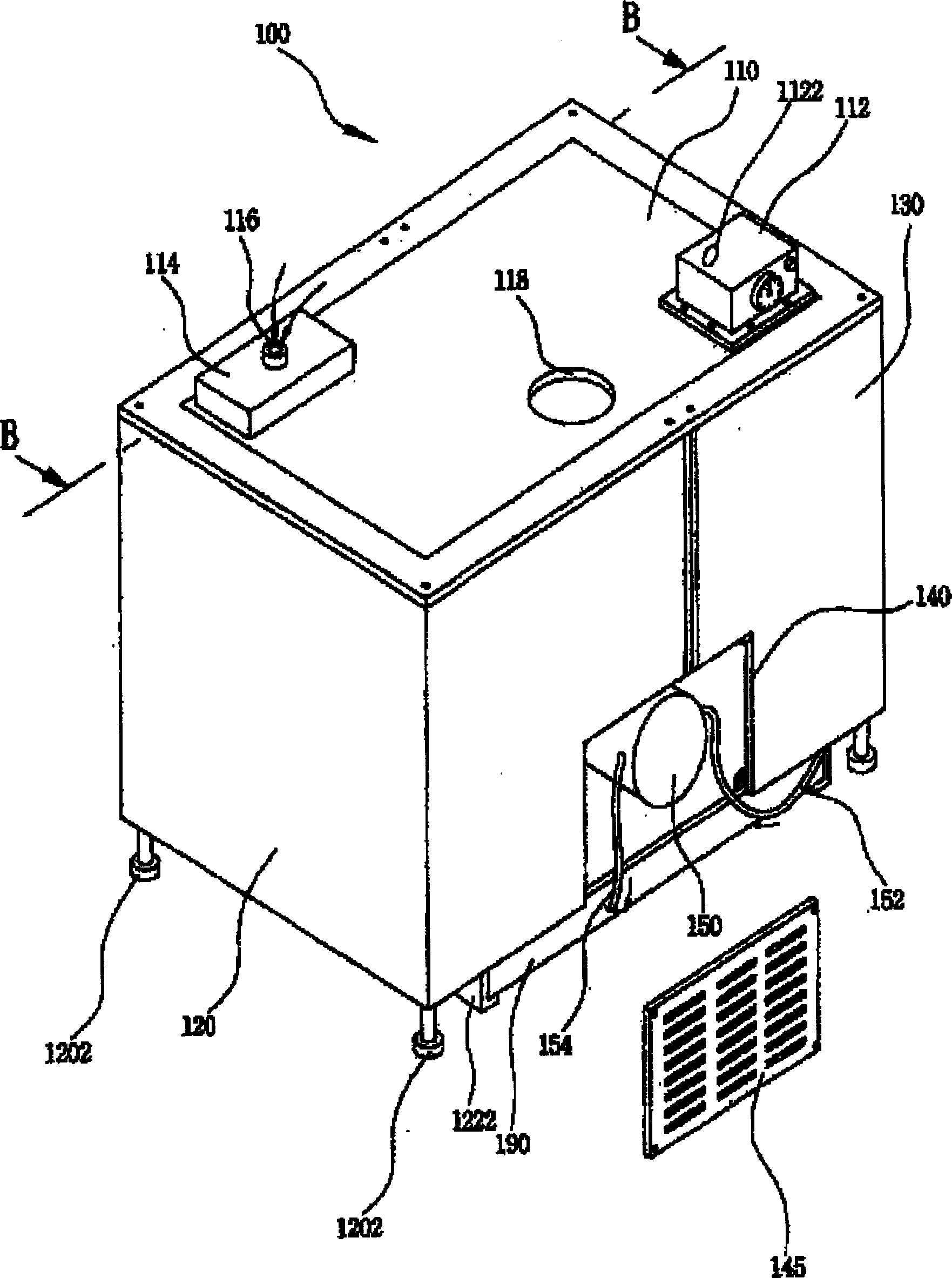

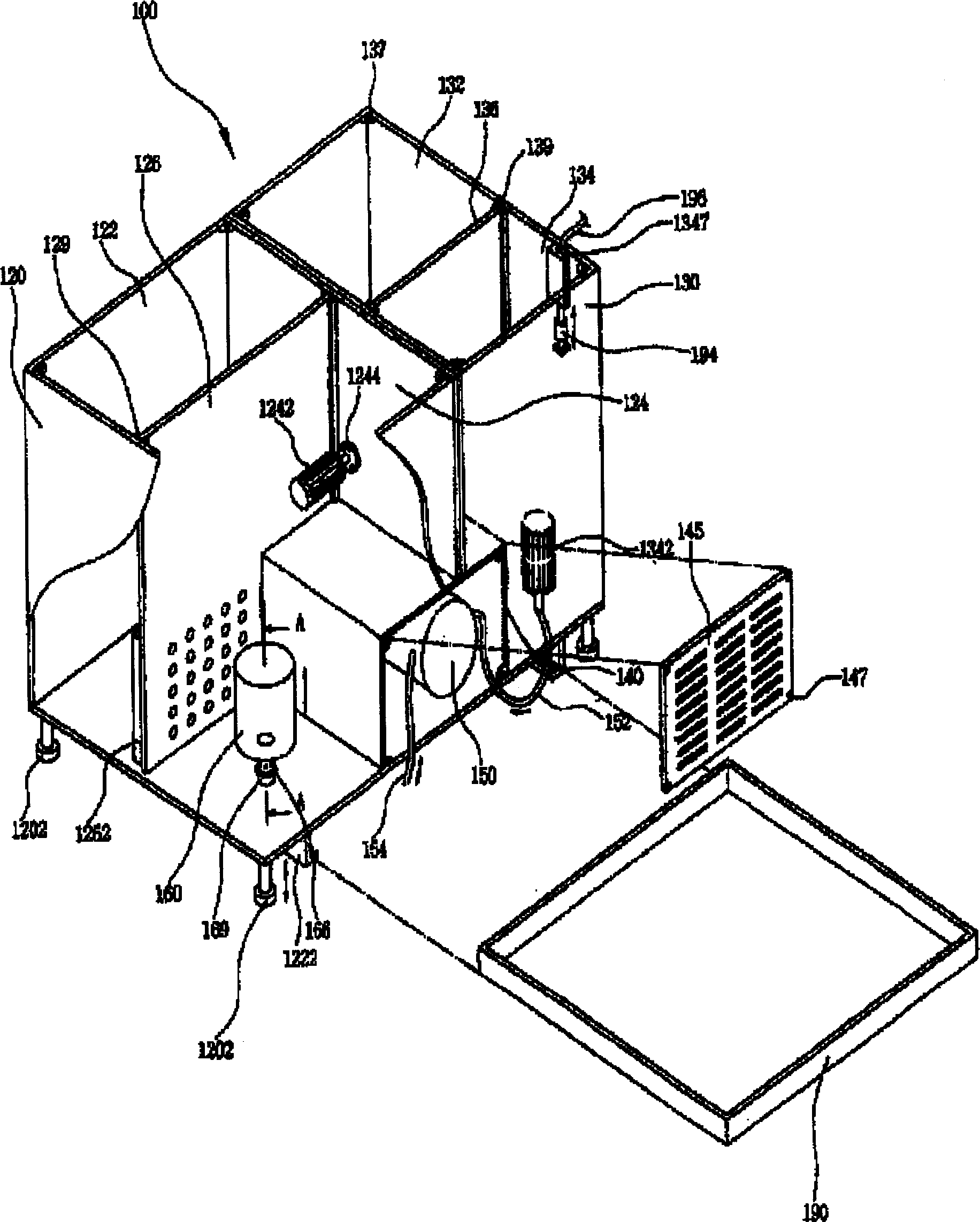

[0020] Preferred embodiments of the lubricating oil circulation supply device according to the present invention and related technologies will be described in detail below with reference to the accompanying drawings.

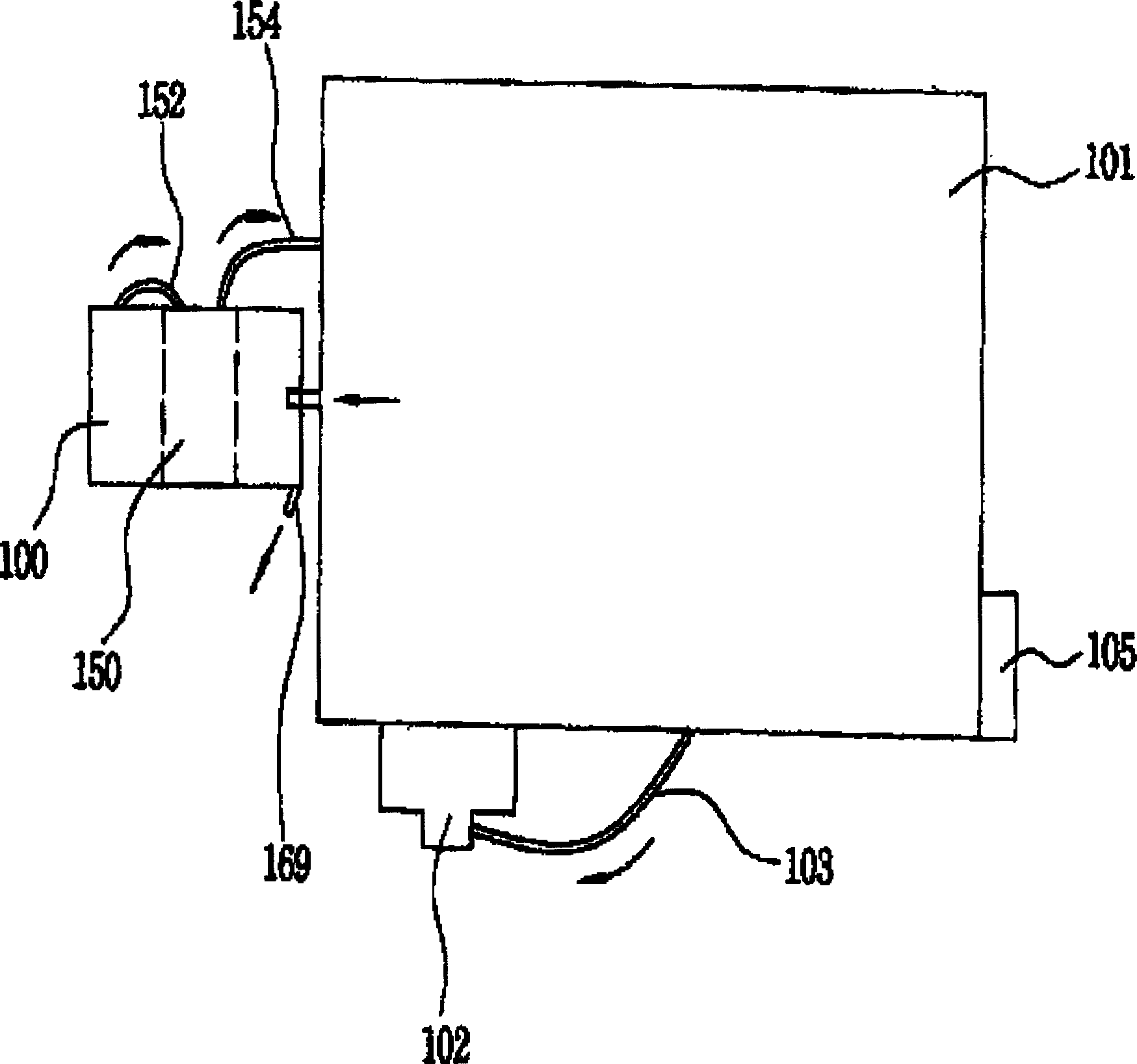

[0021] figure 1 is a block diagram illustrating the structure of lubricating oil circulation supply equipment in the present invention. exist figure 1 Among them, the reference numeral 101 represents a common catapult, the reference numeral 105 represents a common control panel for controlling the catapult 101, and the reference numeral 102 represents a commonly used solenoid valve, which is used to output a control signal through the oil pressure so as to control the catapult 101. installed drive unit. The present invention also provides a lubricating oil circulation supply device 100 , which is connected to the side of the catapult 101 through a second supply conduit 154 for filtering the lubricating oil from the catapult 101 and then supplying the lubricati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com