Sensitive optical cable for long distance oil-gas pipeline safety detection

A technology for oil and gas pipelines and safety detection. It is applied in the direction of using optical devices to transmit sensing components, measuring devices, and fluid tightness testing. It can solve the problems that optical cables cannot detect and effectively detect pressure and vibration signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

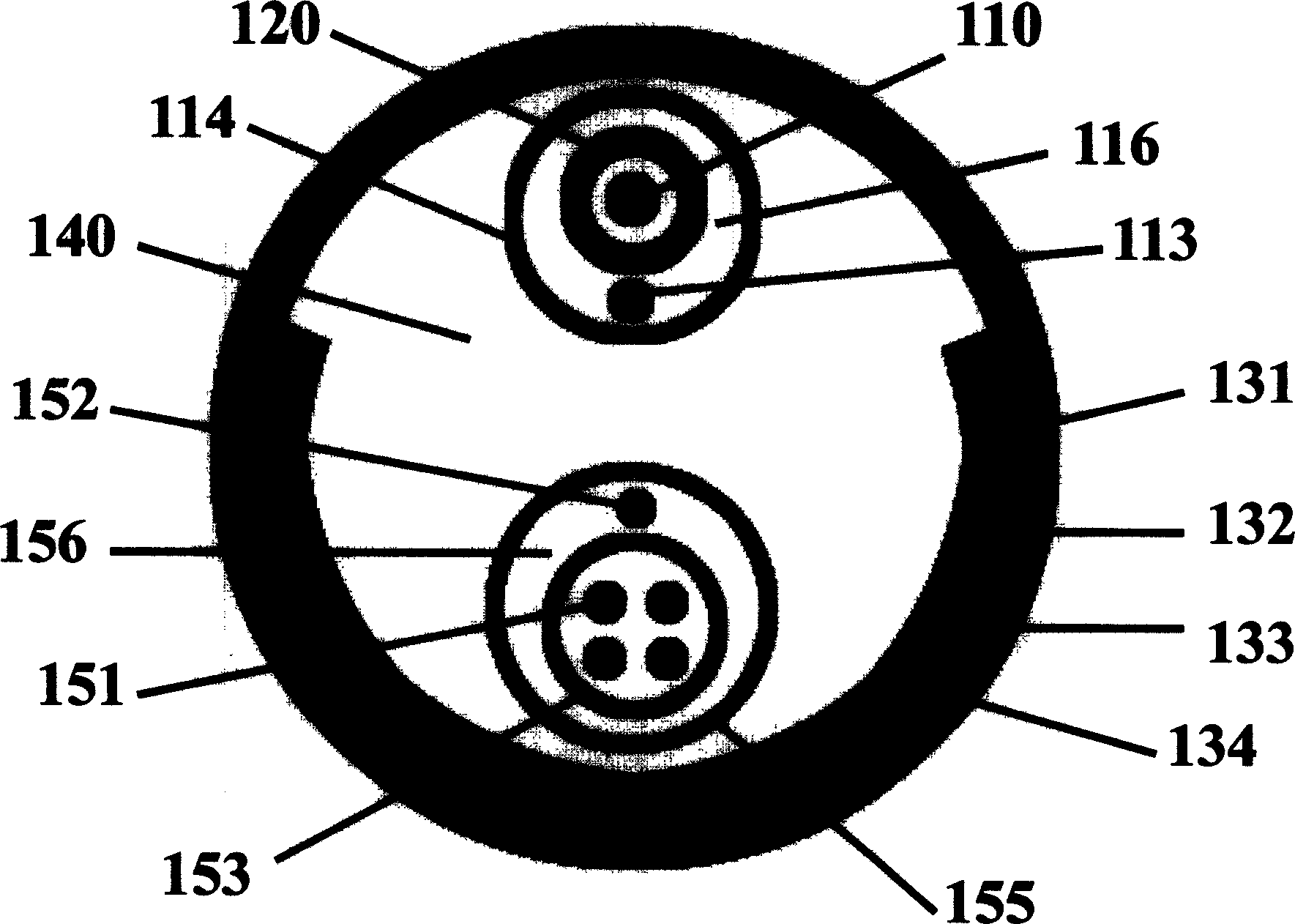

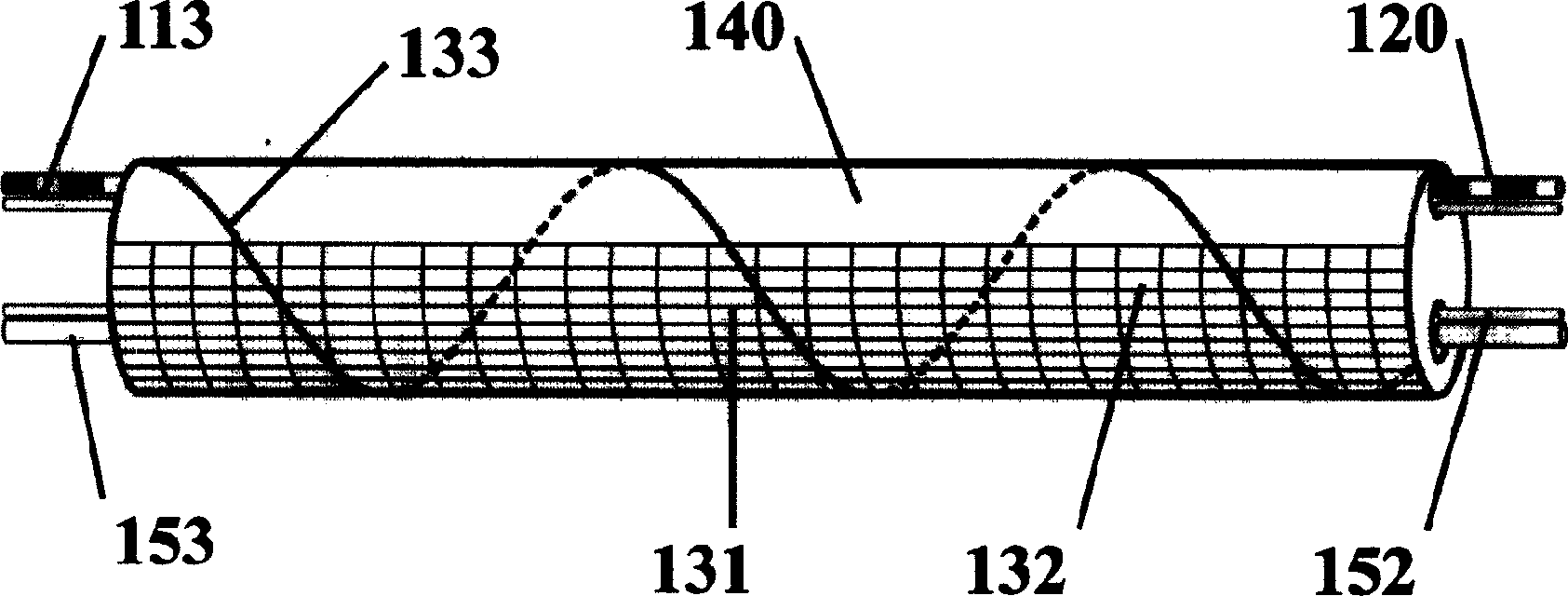

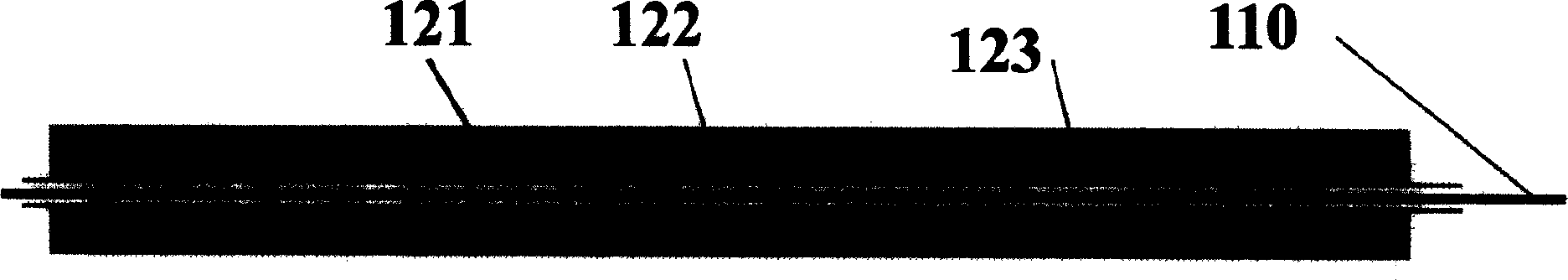

[0016] see figure 1 , figure 2 with image 3 The sensor optical cable for safety detection of the oil and gas pipeline includes a rubber rope 140, and the center diameter on the inner diameter of the rubber rope 140 has a first round hole 114 and a second round hole 155 eccentrically arranged with the rubber rope 140; the first round hole 114 A tight sleeve 120 and a bundle of high-strength aramid yarns 113 for providing tensile strength placed in parallel with the tight sleeve 120 are installed inside, and a sensing optical fiber 110 is housed in the central circular hole 123 of the tight sleeve 120; There is a loose tube 153 and another bundle of high-strength aramid yarn 152 for providing tensile strength in the second circular hole 155, and there are multiple optical fibers 151 for communication between pipeline control stations in the loose tube 153; One side of the second circular hole 155 of the rubber rope 140 is provided with a layer of mesh cloth 131 larger than 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com