Process for production of hydrogel particles and process for cutting of high-concentration hydrogel sheet

A technology of hydrogel particles and hydrogel sheets, which is applied in metal processing and other directions, can solve the problems of reduced manufacturing efficiency, difficulty in ensuring the thickness of cutting continuous sheets, and slow running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

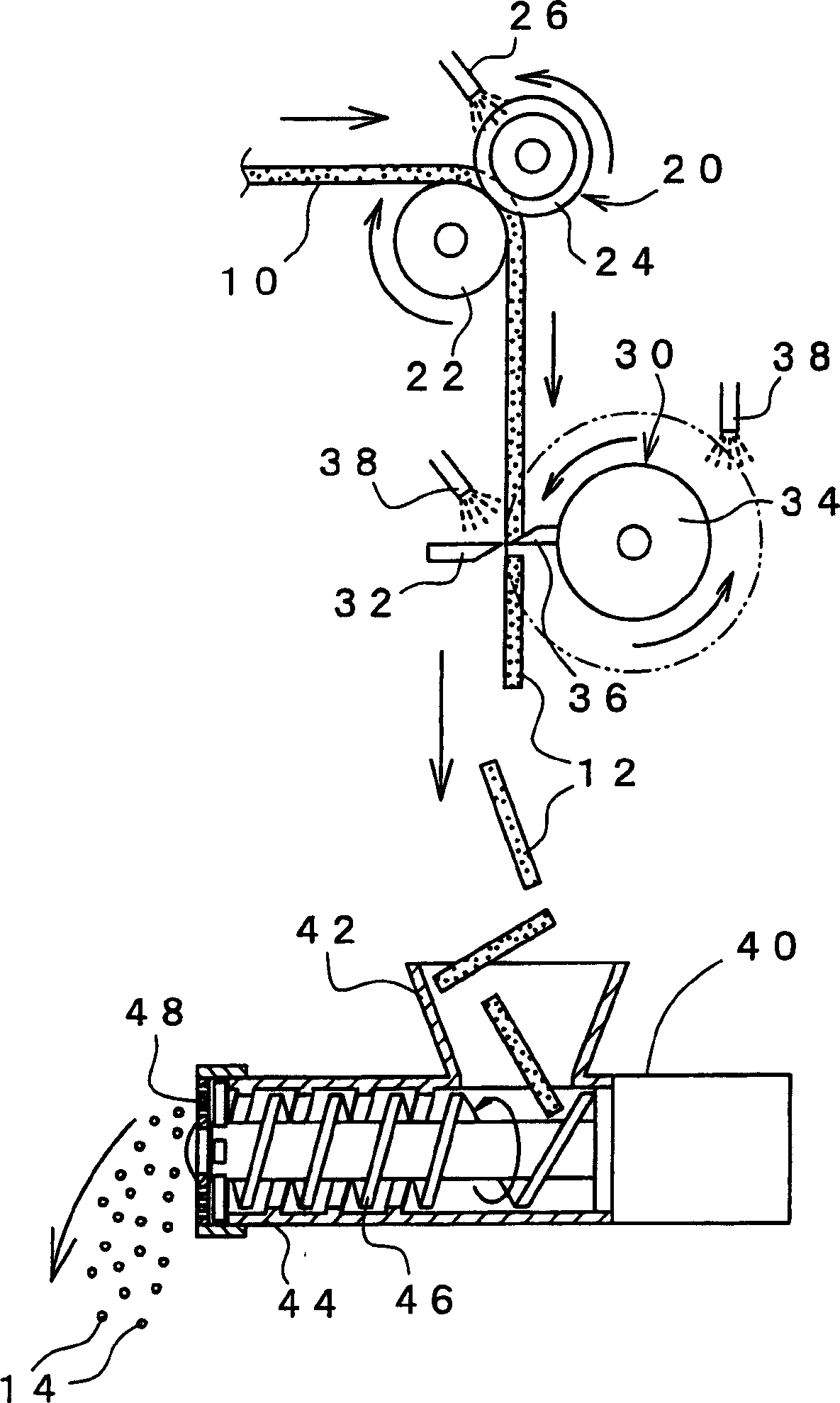

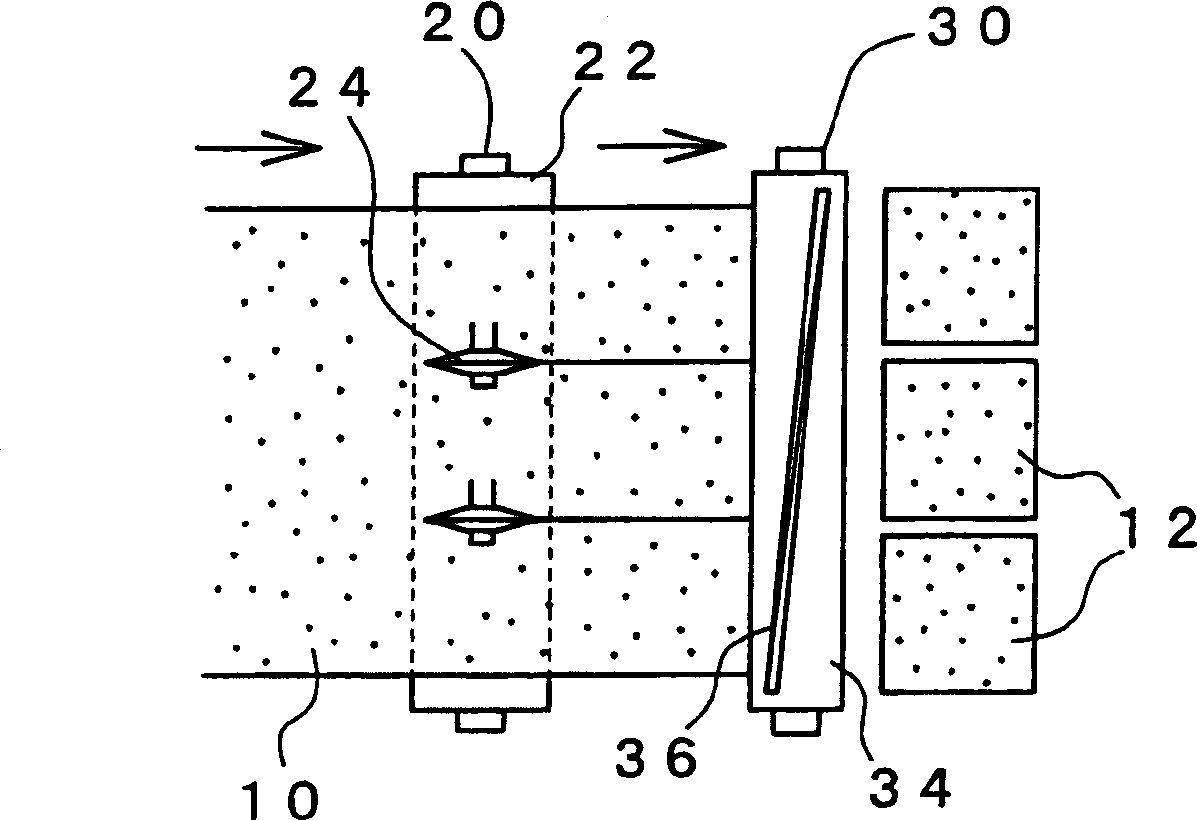

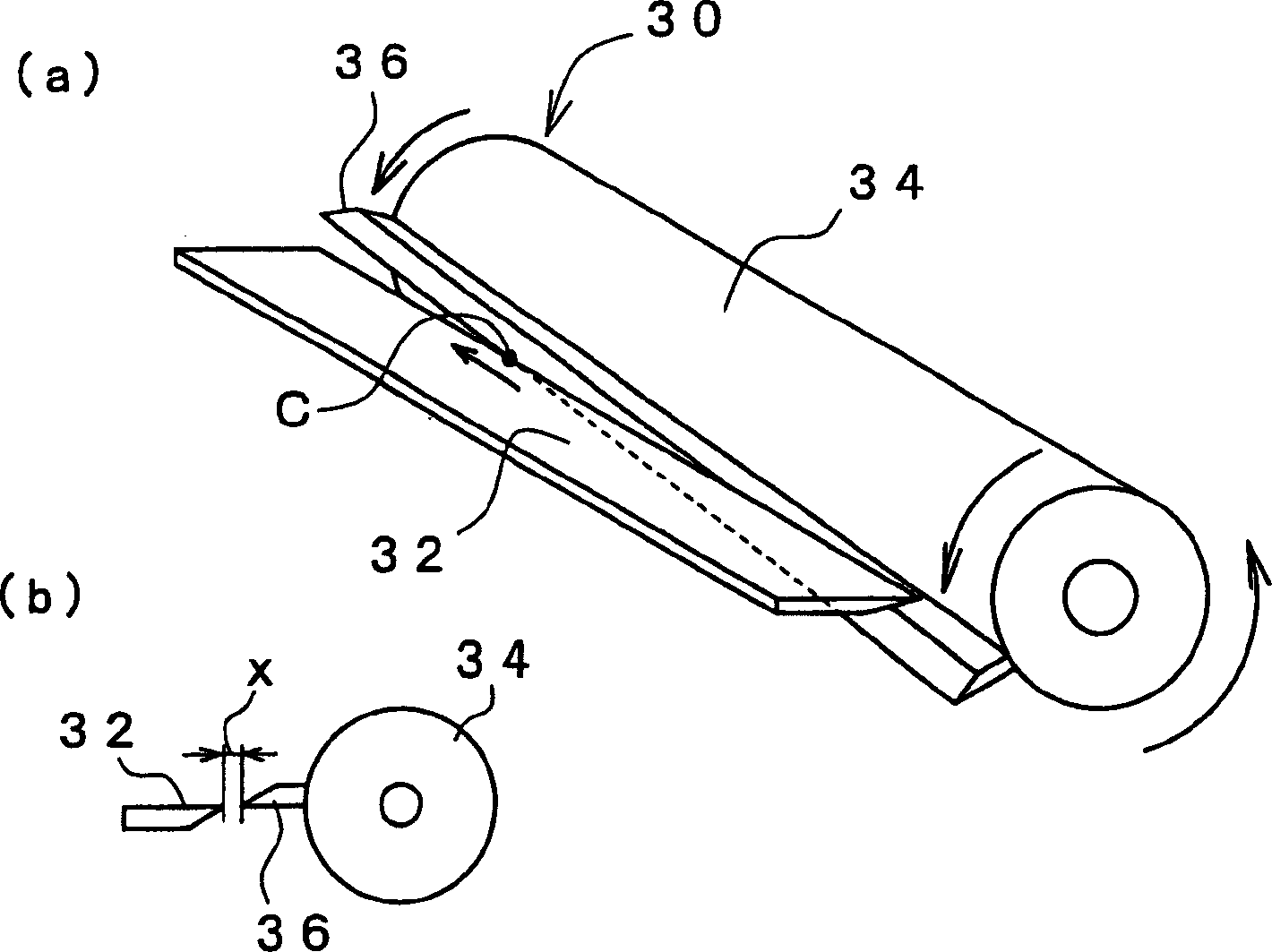

[0177] Such as Figure 6 The illustrated embodiment of the invention differs from the above-described embodiments of the invention in the arrangement of the slitter 20 and the cutter 30 .

[0178] The continuous sheet 10 , which is slit longitudinally by means of passing through the slitter 20 , does not run vertically downwards as a result, but obliquely downwards. The conveyor 50 is provided on the downstream side of the slitter 20, and the conveying surface of the conveyor 50 is inclined downward. The conveying surface of the conveyor 50 is treated by, for example, a fluororesin process so as to reduce its degree of adhesion to the continuous sheet 10 .

[0179] The cutter 30 is disposed obliquely below the conveyor 50 on the downstream side thereof. The continuous sheet 10 is cut longitudinally by a cutting machine 30, and the resulting cut pieces 12 fall freely. As a result, they initially move obliquely downward due to the inertia of operation until they are separated...

Embodiment 1

[0192] :

[0193] The following solutions at predetermined flow rates were stirred and mixed together to prepare a monomer liquid.

[0194] 48.5% by weight aqueous sodium hydroxide solution 73.5g / s

[0195] 53.9% by weight aqueous acrylic acid solution 169.2g / s

[0196] By dissolving 77.4 parts by weight of 50% by weight aqueous acrylic acid solution, 0.781 parts by weight of 2-hydroxymethyl-2-methylphenyl ethyl ketone, and 0.849 parts by weight of 46% by weight aqueous pentasodium diethylenetriaminevaleric acid solution , and 21.0 parts by weight of polyethylene glycol diacrylate (average molecular weight: 523) were dissolved together to prepare a solution of 1.43 g / s.

[0197] The temperature of the resulting monomer liquid stabilized at about 95°C.

[0198] The monomer liquid is continuously supplied to the supply line and continuously stirred in the supply line, and then a 3% by weight aqueous sodium persulfate solution is fed into the monomer liquid at a flow rate of 3...

Embodiment 2

[0215] :

[0216] A continuous sheet composed of a hydrogel sheet manufactured by the same process as in Example 1 was supplied to the slitter using a conveyor belt.

[0217] The slitter used was the same press-cut slitter as in Example 1, except that both the press-cut slitter blade and the receiving roll were coated with fluororesin. In the same manner as in Example 1, the continuous sheet was laterally divided into four with a width of 20 cm.

[0218] The continuous sheet hanging vertically from the slitter is supplied to the cutting machine.

[0219] The structure of the cutting machine is basically the same as that of Embodiment 1, but its fixed blade and receiving roller are coated with fluororesin. The continuous sheet was continuously cut at intervals of 15 cm along the longitudinal direction of the continuous sheet at a rotation speed of the rotator of 30 rpm. Obtain a rectangular cut piece of almost 20cm x 15cm. It was observed that the continuous sheet did not s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com