Synthesis method of mesoporous molecular sieve

A technology of mesoporous molecular sieve and synthesis method, applied in the field of synthesis of mesoporous molecular sieve, can solve the problems of increasing synthesis cost, restricting large-scale feeding production and wider application, and no reports, and achieving the effect of reducing synthesis cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

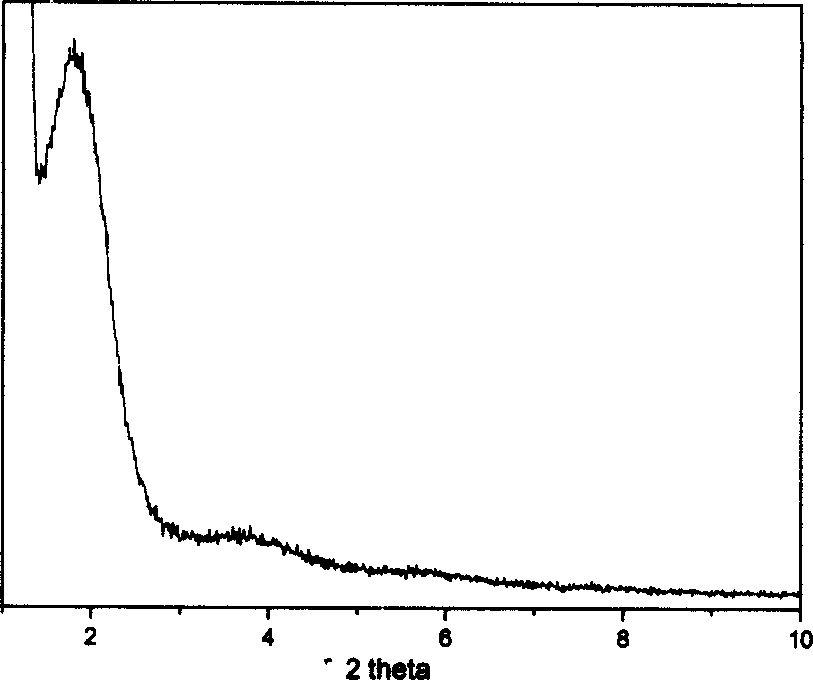

[0027] According to the ratio: 4Na 2 O: 80SiO 2 :Al 2 o 3 : 1500H 2 O is sequentially added to water glass (SiO 2 : 3.782 mol / L, Na 2 O: 1.142 mol / L) 158.8 ml, 71.4 ml deionized water, 12.4 ml H 2 SO 4 (6.12 mol / L) and Al with a concentration of (0.8847 mol / L) 2 (SO 4 ) 3 8.48 milliliters of solutions, stirred for 60 minutes and mixed evenly to generate a white gel, then the above-mentioned mixture without high-temperature hydrothermal pretreatment was added to a cetyltrimethylammonium bromide (CTAB) solution with a concentration of 0.06 g / ml , adjust the pH value to about 11 with dilute sulfuric acid, and the molar composition of the final crystallization reaction system is: 80SiO 2 :Al 2 o 3 :4CTAB:2400H 2 O. Stir at room temperature for 30 minutes, then transfer to a stainless steel reactor, crystallize at 100°C for 72 hours, cool to room temperature, filter the product, wash, dry at 80°C for 12 hours, and roast the dried sample at 540°C for 6 hours to remove ...

Embodiment 2

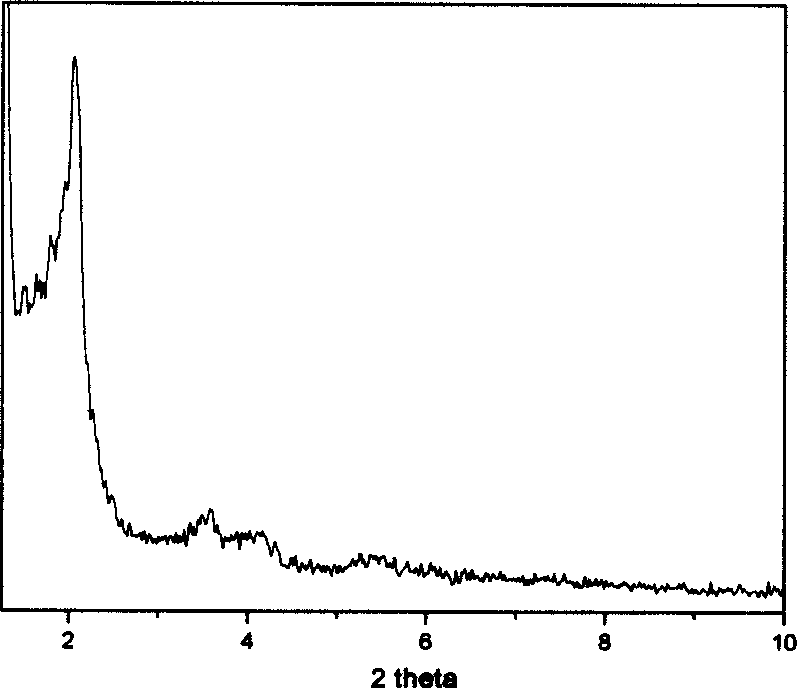

[0030] According to the ratio: 4Na 2 O: 40SiO 2 :Al 2 o 3 : 1000H 2 O is sequentially added to water glass (SiO 2 : 3.782 mol / L, Na 2 O: 1.142 mol / L) 79.4 ml, 47.6 ml deionized water, 6.24 ml H 2 SO 4 (6.12 mol / L) and Al with a concentration of (0.8847 mol / L) 2 (SO 4 ) 3 The solution was 8.48 milliliters, stirred for 60 minutes to mix evenly, and a white gel was formed, and reacted at 140° C. for 32 hours. Then the above-mentioned pretreated mixture is added into a cetyltrimethylammonium bromide (CTAB) solution with a concentration of 0.06 g / ml, and the pH value is adjusted to about 10.5 with dilute sulfuric acid, and the moles of the final crystallization reaction system The composition is: 40SiO 2 :Al 2 o 3 :4CTAB:2400H 2 O. Stir at room temperature for 30 minutes, then transfer to a stainless steel reactor, crystallize at 100°C for 72 hours, cool to room temperature, filter the product, wash, dry at 80°C for 12 hours, and roast the dried sample at 540°C for 6...

Embodiment 3

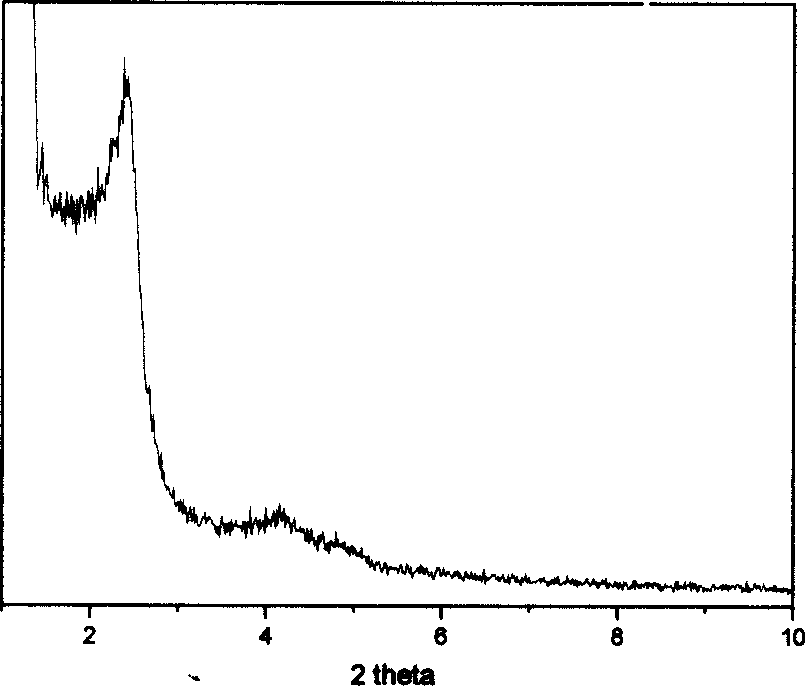

[0032] The preparation of the colloidal ZSM-5 gel was the same as in Example 2, and the resulting gel was reacted at 140° C. for 46 hours. Then the above-mentioned pretreated mixture is added to the cetyltrimethylammonium bromide (CTAB) solution with a concentration of 0.06 g / ml, and the pH value is adjusted to about 10 with dilute sulfuric acid, and the moles of the final crystallization reaction system The composition is: 40SiO 2 :Al 2 o 3 :4CTAB:2400H 2 O. Stir at room temperature for 30 minutes, then transfer to a stainless steel reactor, crystallize at 100°C for 72 hours, cool to room temperature, filter the product, wash, dry at 80°C for 12 hours, and roast the dried sample at 540°C for 6 hours to remove Template agent to obtain the said mesoporous molecular sieve of the present invention. Its XRD pattern is as follows image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com