Temperature transducer for optical fiber grating steel tube packaging

A temperature sensor and optical fiber grating technology, applied in the field of sensing, can solve the problems that the temperature sensor is easily affected by external electromagnetic interference, easily affected by external stress, and the bare optical fiber grating is easy to break, and achieves simple structure, low cost, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

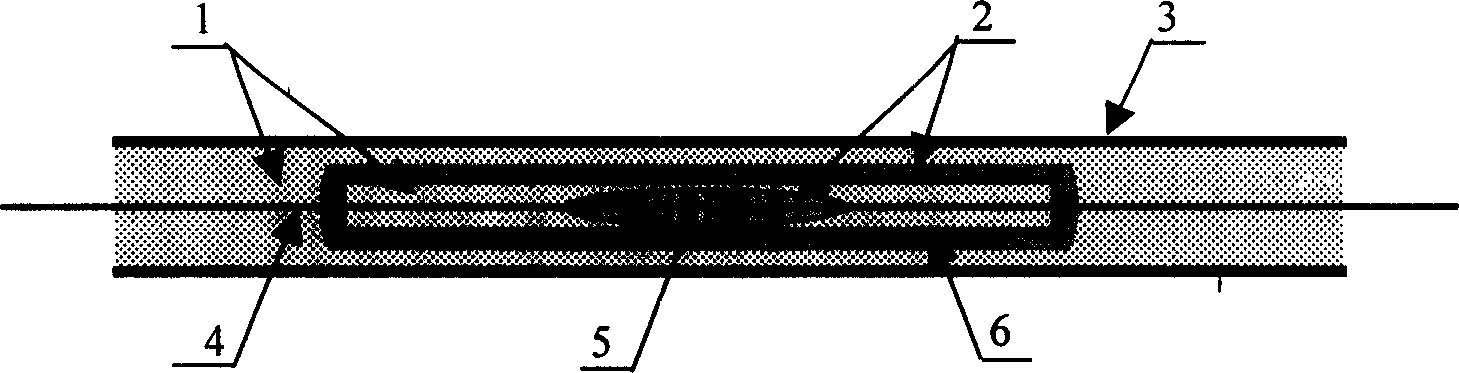

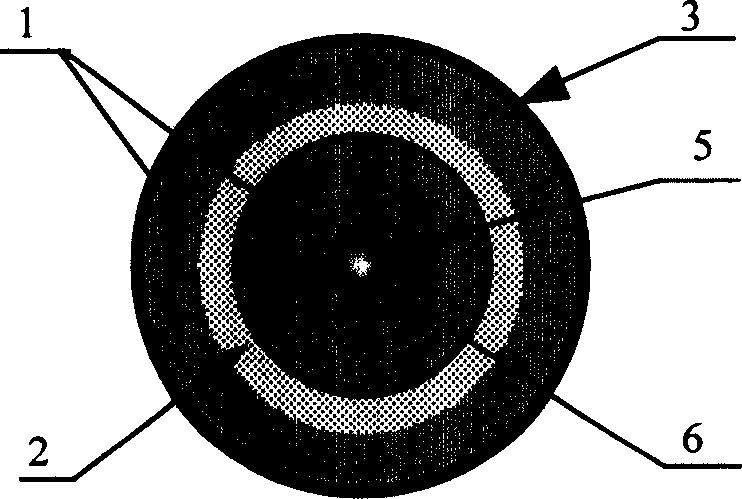

[0012] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0013] The schematic diagram of the lateral section structure of the new fiber grating steel pipe package temperature sensor proposed by the present invention is attached. figure 1 As shown, the schematic diagram of the tangential section structure is shown in the attached figure 2 shown. The specific method of encapsulation is to firstly coat a layer of 703 glue 2 on the grid area of the bare fiber grating 5, place the fiber grating 5 in a 1.5mm steel pipe 6 after curing, and adjust its position with a precision optical fiber adjustment frame so that it is in the Then pour epoxy resin glue 1 into the central part. After the epoxy resin glue 1 is cured, place the 1.5mm steel pipe 6 whose outer wall is evenly coated with 703 glue 2 on the central part of the outer 3mm steel pipe 3, and then pour epoxy resin into it. Glue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com