Cutting device and method

A technology of cutting device and predetermined position, applied in capacitor manufacturing, electrical components, fixed capacitor dielectric, etc., can solve problems such as low processing speed, waste of time, cutting device cannot detect time, etc., achieve high-speed processing and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] [Device outline configuration, figure 1 , figure 2 ]

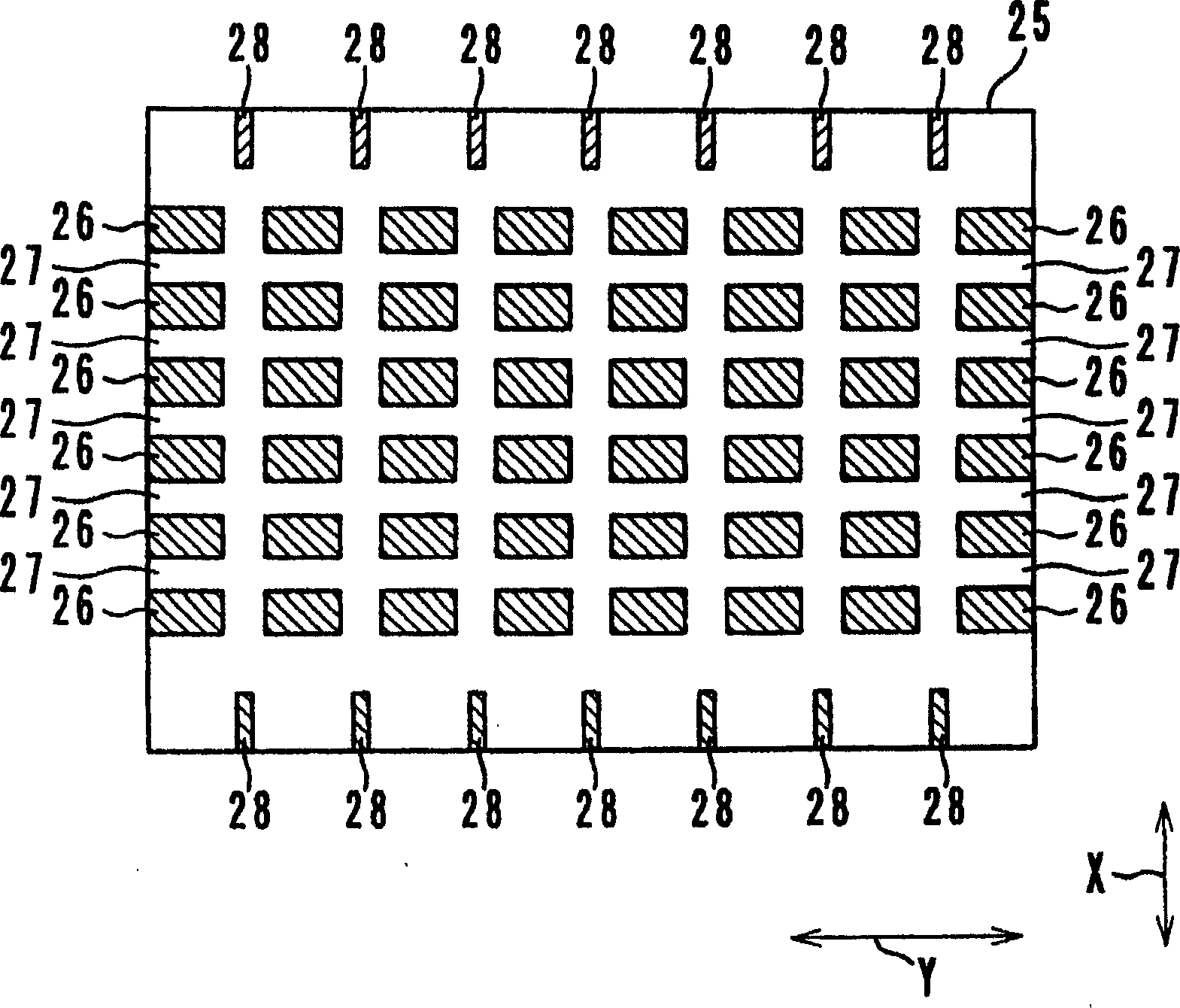

[0045] The manufacture of laminated ceramic capacitors usually goes through the following processes in sequence, including laminating multiple ceramic raw material substrates with multiple internal electrodes on the surface, and pressurizing them to form unsintered ceramic laminated blocks; The process of cutting the ceramic laminated block according to the configuration of the internal electrodes and cutting it into pieces of laminated ceramic chips; the process of sintering the cut laminated ceramic chips; and the process of forming external electrodes on the sintered laminated ceramic chips.

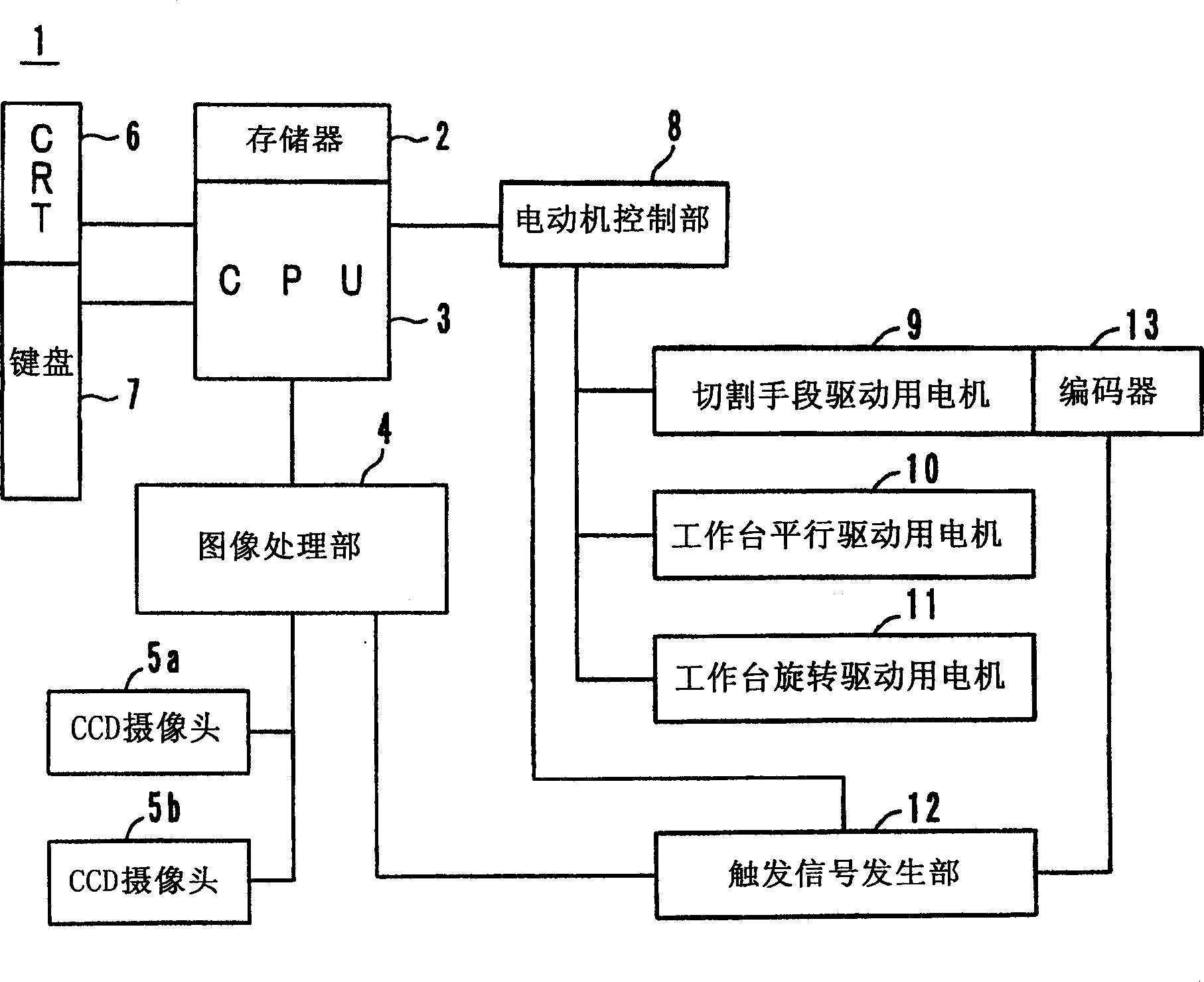

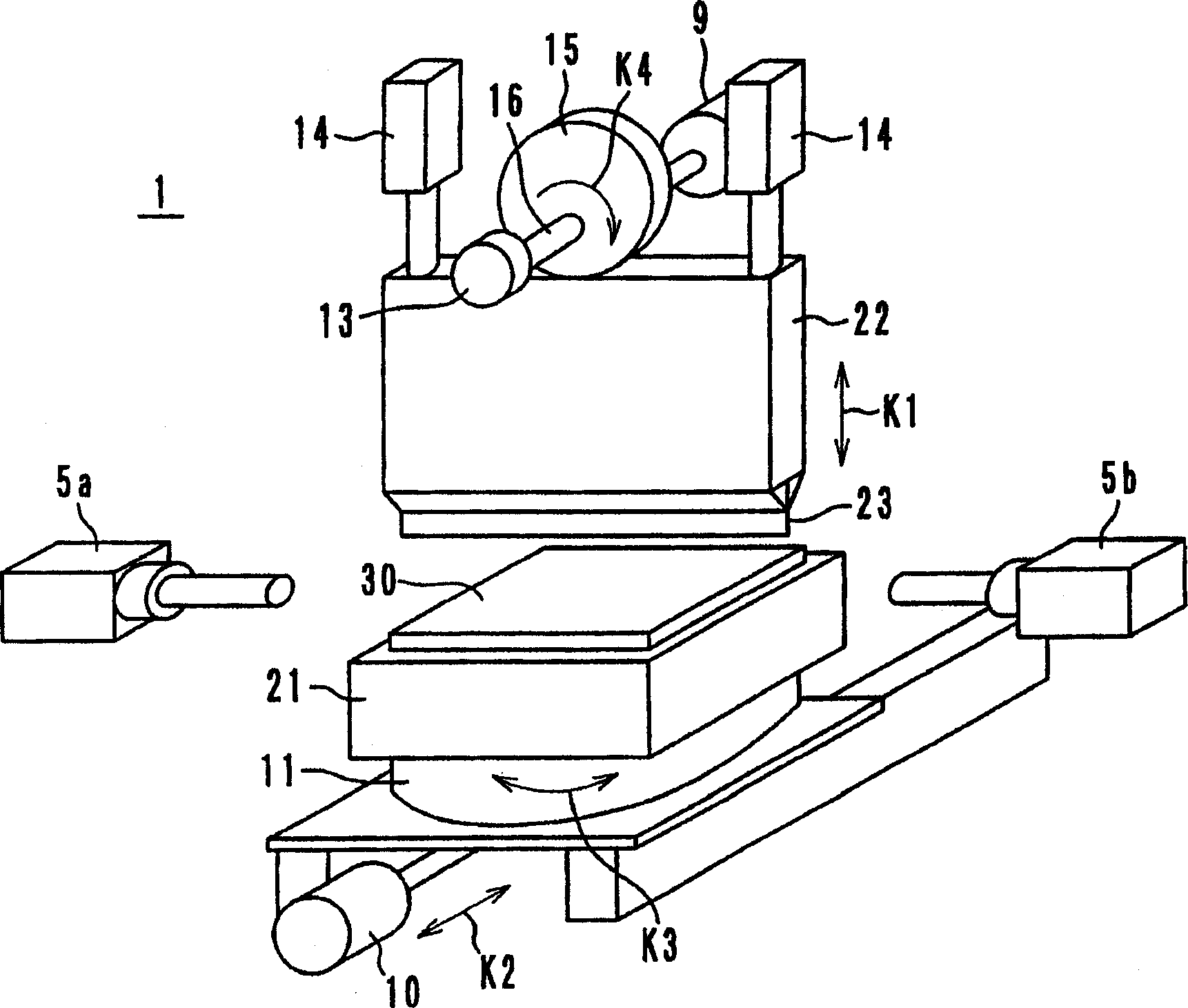

[0046] In this example, the cutting process adopts the system configuration shown in figure 1 , while the mechanical composition is shown in figure 2 The cutting device 1 to carry out. Cutting device 1 is made up of memory 2, computing unit (CPU) 3, image processing unit 4, CCD camera 5a, 5b, display unit (displays su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com