Method of preparing organic fertilizer from restaurant refuse by wet hot heating process

A technology of catering waste and organic fertilizer, which is applied in the field of solid waste treatment and disposal, can solve the problems of low treatment temperature and inability to completely kill germs, achieve the effects of improving processing performance, easy and complete sterilization, and improving physical processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

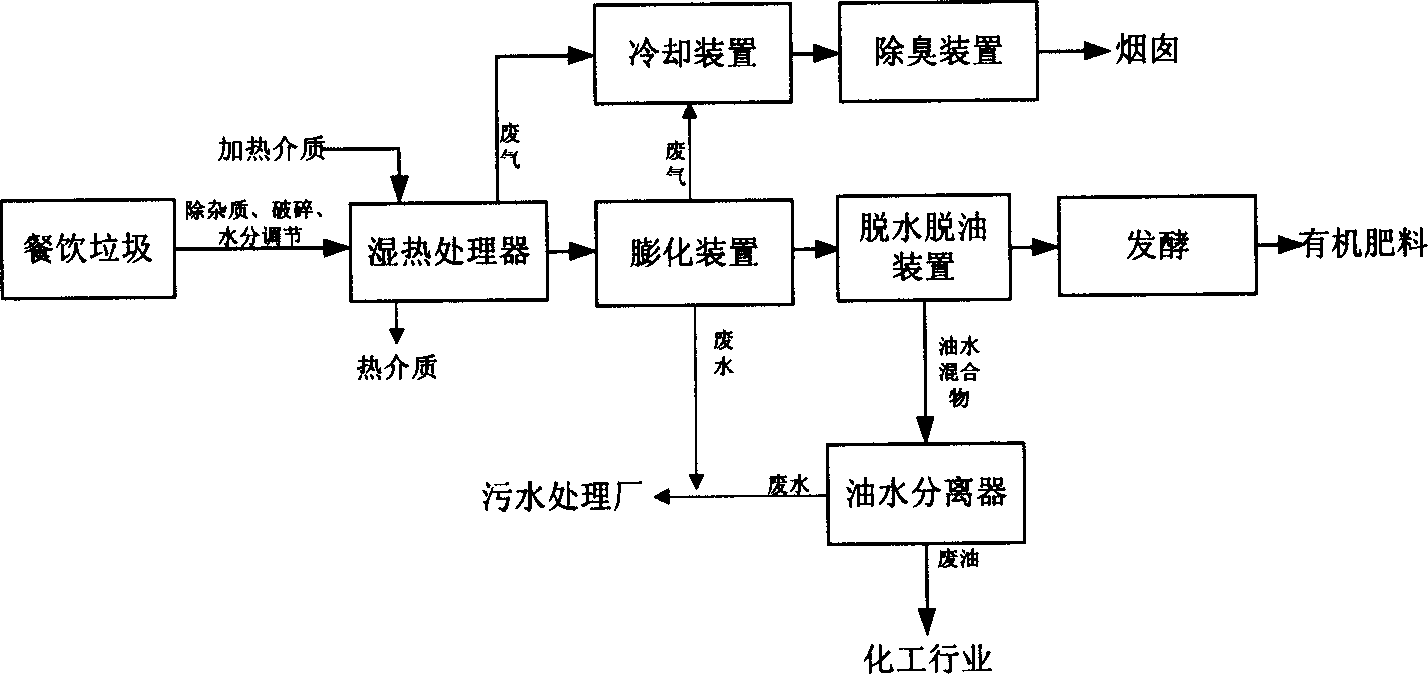

Image

Examples

Embodiment 1

[0031]The amount of catering waste generated by a single restaurant is small, and its on-site treatment adopts a small-scale wet heat treatment process. When collecting catering waste, remove non-nutrient components such as bottle caps, plastic bags, chopsticks, spoons, and metals from catering waste. Then utilize the cutting crusher to cut the thicker, harder materials such as bones in the rubbish into fritters, and the crusher used here can adopt the disclosed cutting crusher of Chinese patent CN1087556. Then put the garbage into the wet heat reactor, adjust the water surface to submerge the solid matter, heat the garbage to 135°C in the water-containing environment, and stay for 30 minutes. The heating method adopts heat conduction oil heating. Gradually release the pressure of the wet heat treated garbage to realize puffing. The method is to connect the wet heat reactor to a container with a volume much larger than it through the solenoid valve, and the container is conne...

Embodiment 2

[0033] The amount of catering waste in the region is relatively large, and the centralized treatment of catering waste adopts a large-scale wet heat treatment process. When collecting catering waste, remove non-nutrient components such as bottle caps, plastic bags, chopsticks, spoons, and metals from catering waste. Transport the catering waste generated by the catering units in the area to the centralized treatment plant. Utilize the cutting crusher to cut the thicker and harder materials such as bones in the garbage into small pieces. The crusher used here can adopt the cutting crusher disclosed in Chinese patent CN1087556. Then send the garbage to the wet heat reactor, adjust the moisture content of the garbage until the liquid surface submerges the solid matter, heat to 135°C for 30 minutes, and use heat transfer oil for heating. Instantly release the pressure of the wet heat treated garbage to realize puffing. The method is to connect the wet heat reactor with the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com