Preparation method of aluminium methide oxyalkane

A technology of methylaluminoxane and alkylaluminum, which is applied in the field of preparation of metallocene cocatalyst-methylaluminoxane, can solve problems such as complex process flow, achieve the effect of simplifying post-processing and solving safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

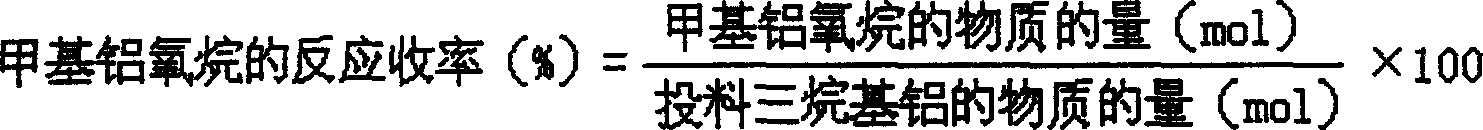

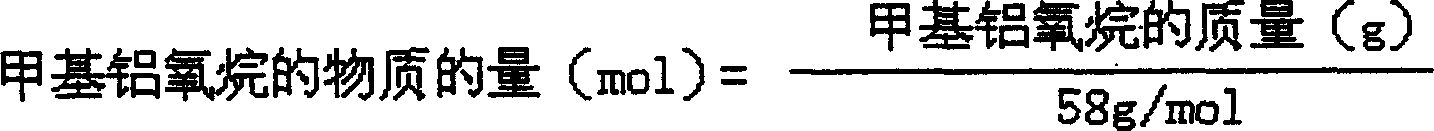

[0020] After the reaction bottle is fully vacuum-nitrogen replaced, add 50ml2mol.L -1 Triethylaluminum (TEA) decane solution, start stirring, add 2gBiCl under inert protection 3 , slowly warming up to 120°C. After the methyl bromide gas is passed through distilled water at 30°C, the methyl bromide entrained with water vapor is passed into the reaction flask. When the number of moles of methyl bromide gas reaches 0.4 mol in total, stop feeding methyl bromide, and continue stirring until no gas is produced, then stop the reaction. The solid was filtered off, and the solvent was removed under reduced pressure to obtain 3.1 g of white methylaluminoxane solid. Calculated based on the moles of triethylaluminum fed, the yield of the target product, methylaluminoxane, is 53.5%.

[0021] 1.7 g of the above methylalumoxane with 0.05 g Cp 2 ZrCl 2 , At 60°C and 0.8Mpa, ethylene was polymerized for 1 hour to obtain 584 grams of polyethylene.

Embodiment 2

[0023] After the reaction bottle is fully vacuum-nitrogen replaced, add 50ml2mol.L -1 Triethylaluminum (TEA) decane solution, start stirring, add 2gBiCl under inert protection 3 , slowly warming up to 120°C. After the methyl bromide gas is passed through distilled water at 50°C, the methyl bromide entrained with water vapor is passed into the reaction flask. When the number of moles of methyl bromide gas reaches 0.45 mol in total, stop feeding methyl bromide, and continue stirring until no gas is generated, then stop the reaction. The solid was filtered off, and the solvent was removed under reduced pressure to obtain 3.5 g of white methylaluminoxane solid. Calculated based on the moles of triethylaluminum fed, the yield of the target product, methylaluminoxane, is 60.3%.

[0024] 1.7 g of the above methylalumoxane with 0.05 g Cp 2 ZrCl 2 , At 60°C and 0.8Mpa, ethylene was polymerized for 1 hour to obtain 651 grams of polyethylene.

Embodiment 3

[0026] After the reaction bottle is fully vacuum-nitrogen replaced, add 50ml2mol.L -1 Triethylaluminum (TEA) toluene solution, start stirring, add 2gBiCl under inert protection 3 , slowly warming up to 100°C. After the methyl bromide gas is passed through distilled water at 50°C, the methyl bromide entrained with water vapor is passed into the reaction flask. When the number of moles of methyl bromide gas reaches 0.5 mol in total, stop feeding methyl bromide, and continue stirring until no gas is generated, then stop the reaction. The solid was filtered off, and the solvent was removed under reduced pressure to obtain 2.9 g of white methylaluminoxane solid. Calculated based on the moles of triethylaluminum fed, the yield of the target product methylaluminoxane is 50%.

[0027] 1.7 g of the above methylalumoxane with 0.05 g Cp 2 ZrCl 2 , At 60°C and 0.8Mpa, ethylene was polymerized for 1 hour to obtain 604 grams of polyethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com