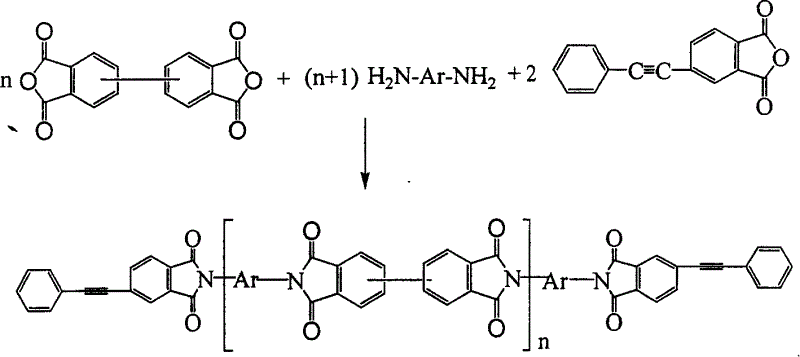

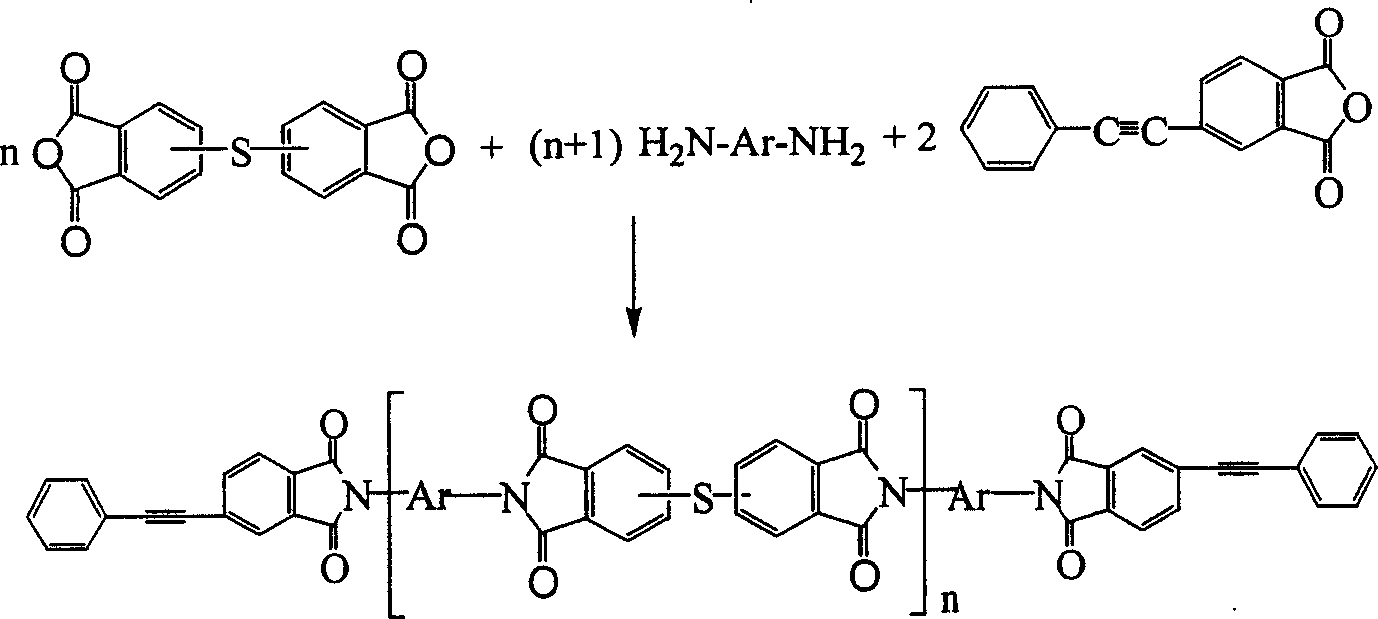

Synthesis of biphenyl type polyimide resin with phenyl ethyne dead-end

A technology of biphenyl type polyimide and phenylacetylene is applied in the synthesis field of biphenyl type polyimide resin, which can solve the problem of high cost and achieve the effects of low cost, good thermal stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Add 0.1mol (32.6g) of 4,4'-biphenyldianhydride, 0.1mol (32.6g) of 1,6-hexanediamine (23.2g, 0.2mol) and 0.1mol (24.8g) of phenylacetylene phthalic anhydride to N, N' - In dimethylformamide (3000ml), after stirring and reacting at room temperature for 12h, add 0.4mol (40g) of dehydrating agent acetic anhydride and 0.04mol (4g) of catalyst triethylamine to continue stirring for 12h, then pour it into a large amount of ethanol , a pale yellow precipitate was precipitated, and the precipitate was collected by filtration, washed thoroughly with ethanol, and dried to obtain 73 g of phenylacetylene-capped polyimide resin.

Embodiment 2

[0018] Add 0.2mol (65.2g) of 3,4'-biphenyldianhydride, 0.3mol (32.4g) of p-phenylenediamine and 0.2mol (49.6g) of phenylacetylene phthalic anhydride to N,N'-dimethylformamide ( 300mL), stirred and reacted at room temperature for 12h, added 1.5mol (153g) of dehydrating agent acetic anhydride and 1mol (101g) of catalyst triethylamine and continued to stir for 12h, then poured it into a large amount of ethanol, precipitated, and collected the precipitate by filtration , and fully washed with ethanol, and dried to obtain phenylacetylene-capped polyimide resin.

Embodiment 3

[0020] Add 0.1mol (32.6g) of 3,3'-biphenyldianhydride, 0.11mol (11.9g) of m-phenylenediamine and 0.02mol (5g) of phenylacetylene phthalic anhydride to N,N'-dimethylformamide (110ml ), after stirring and reacting at room temperature for 12 hours, add 0.44 mol (44 g) of dehydrating agent acetic anhydride and 0.44 mol (44 g) of catalyst triethylamine to continue stirring and reacting for 12 hours, then pour it into a large amount of ethanol, precipitate out, and collect the precipitate by filtration , and fully washed with ethanol, and dried to obtain phenylacetylene-capped polyimide resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com