Technology of changing railway switch construction and its equipment of changing railway switch

A construction technique and turnout technology, which is applied in the field of railway turnout replacement construction technology, can solve problems such as inability to use crowbars, high cost, out-of-sync operation of rack presses, etc., so as to save manpower moving process, improve safety and reliability, The effect of large application promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

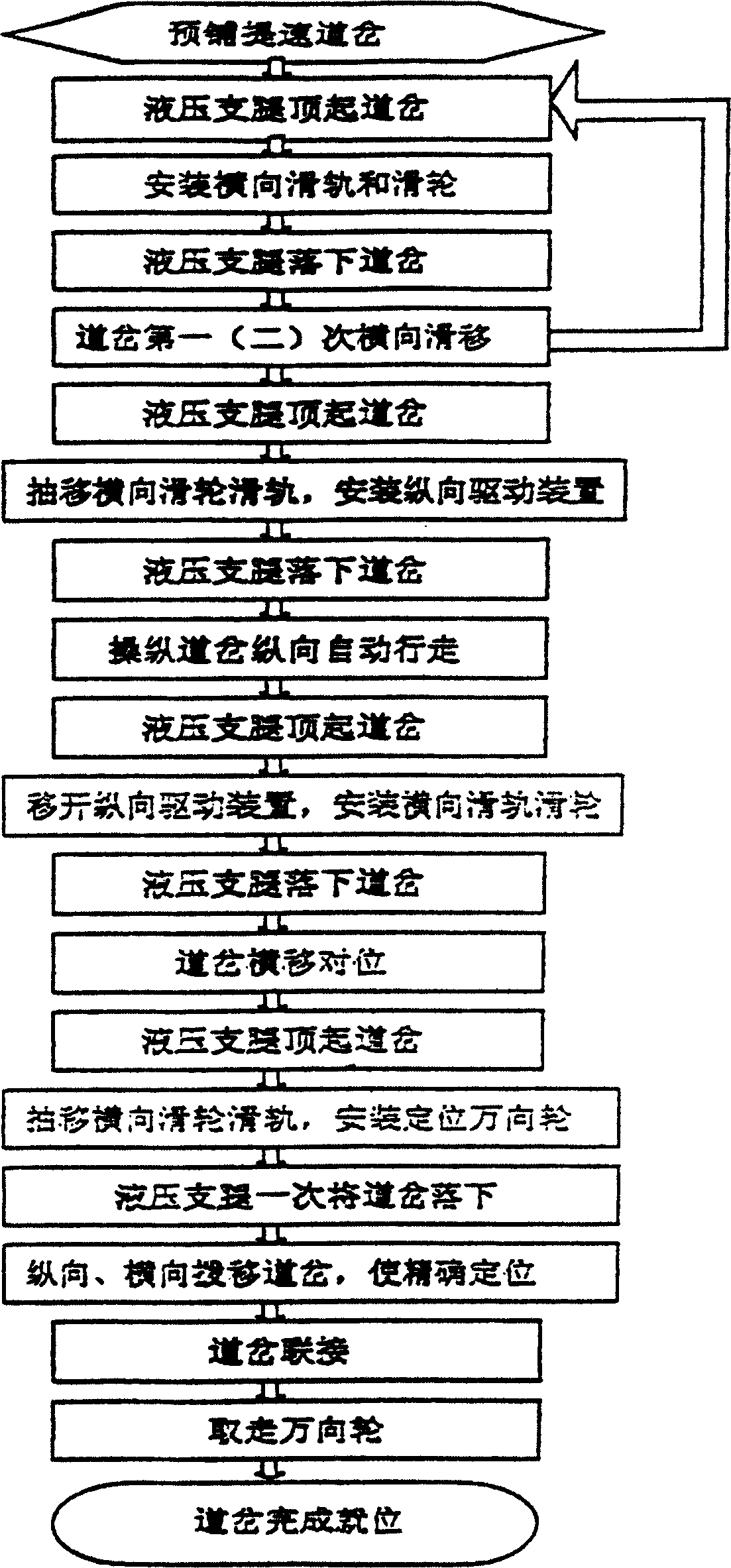

[0039] Below in conjunction with accompanying drawing and specific embodiment, the construction technique and switch relaying equipment of the present invention are described in detail.

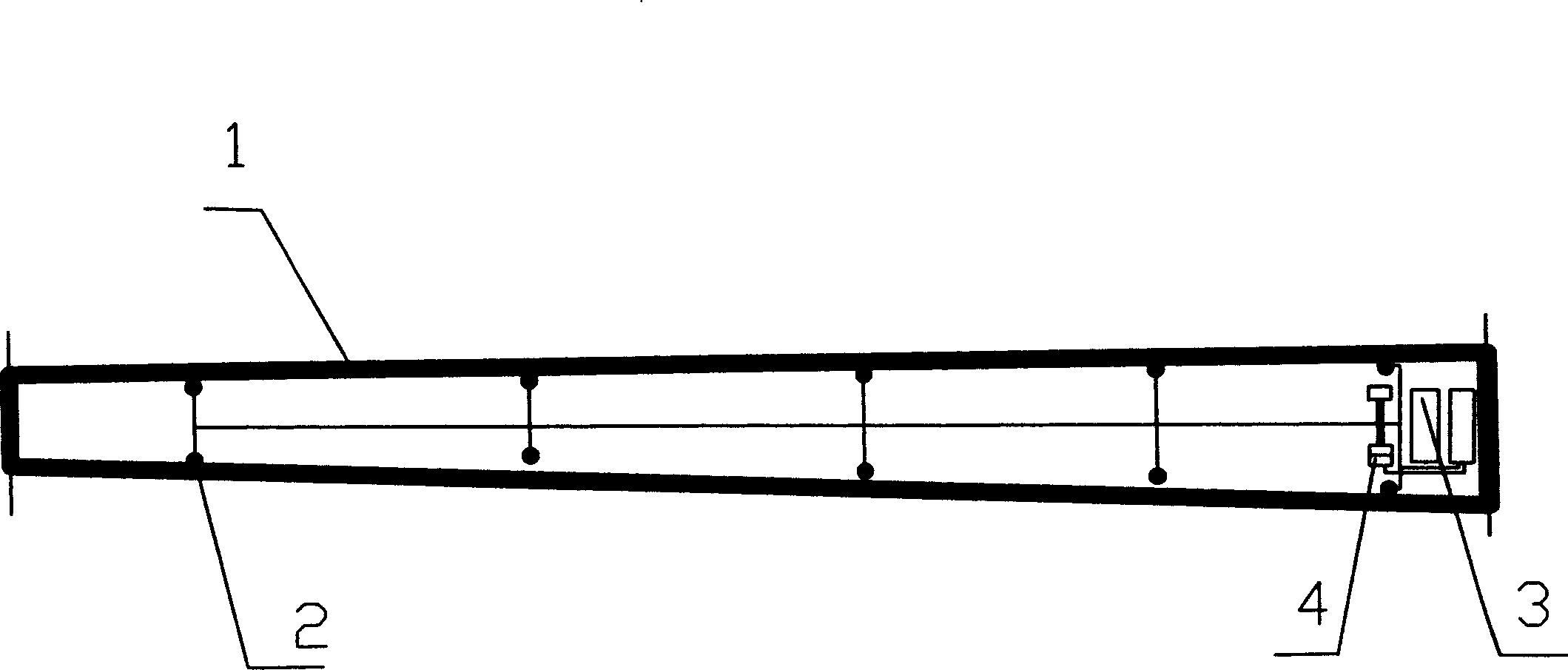

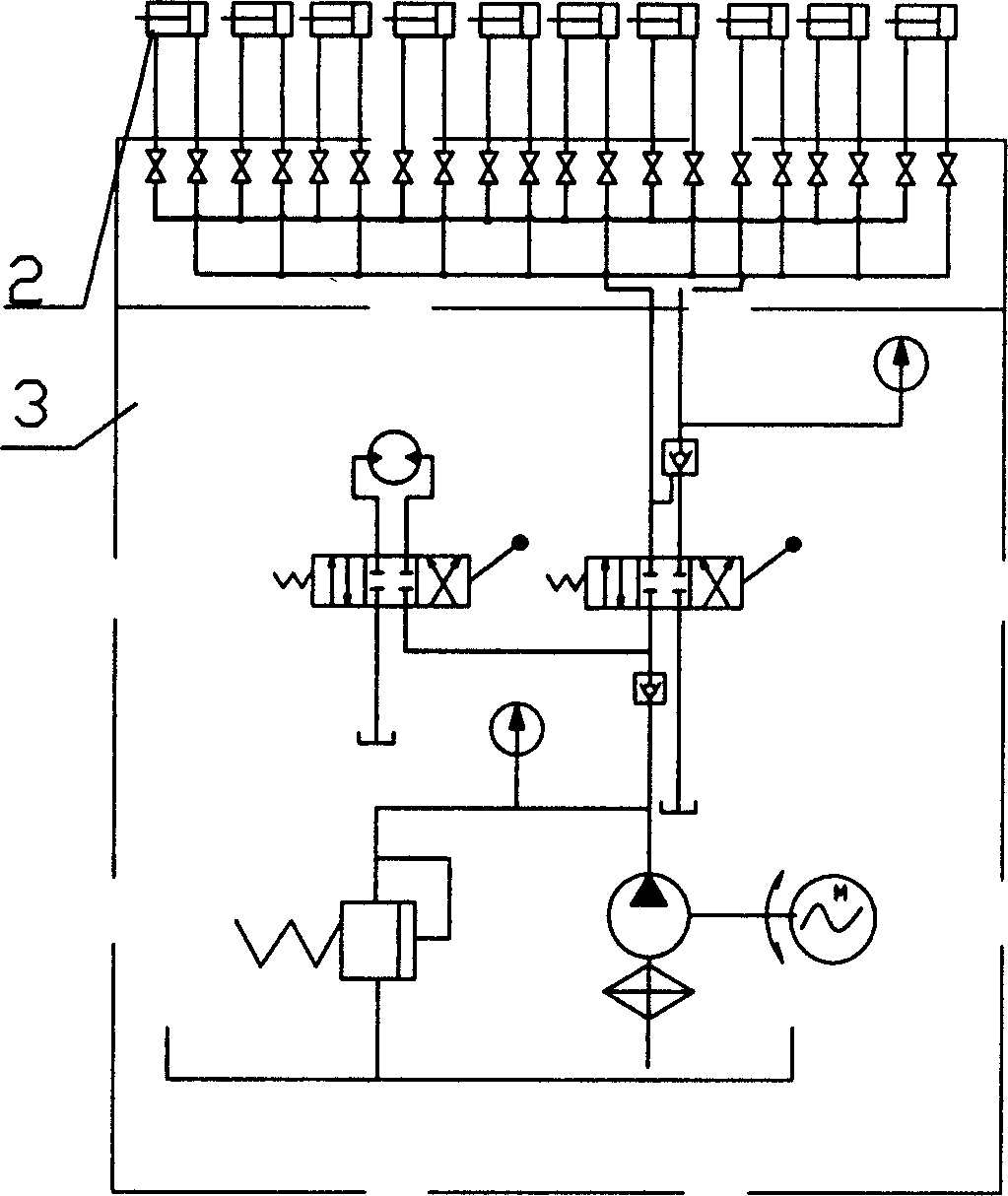

[0040] see figure 2 and image 3 The turnout changing equipment consists of a hydraulic pump station 3, multiple sets of turnout jacking devices 2 connected with the hydraulic pump station 3, a set of turnout longitudinal driving device 4, vertical and horizontal support two-wheeled vehicles, horizontal slide rails, and universal wheel devices and supporting iron plates and other components, see Figure 5 The turnout longitudinal driving device 4 is provided with a drive wheel 14 and a driven wheel 17 on the coupling shaft 18, and a travel motor 13 connected with the drive wheel 14 is also provided on the coupling shaft 18, and a driving seat is also provided on the coupling shaft 18. 15 and follower seat 16; see Figure 4 The turnout jacking device 2 is that the piston rod of the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com