Winding machine system

A winding machine, a new type of technology, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve the problems of unstable winding pressure, inconvenient operation, inaccurate positioning, etc., and achieve convenient spindle speed adjustment , Convenient assembly and maintenance, and convenient mobile operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

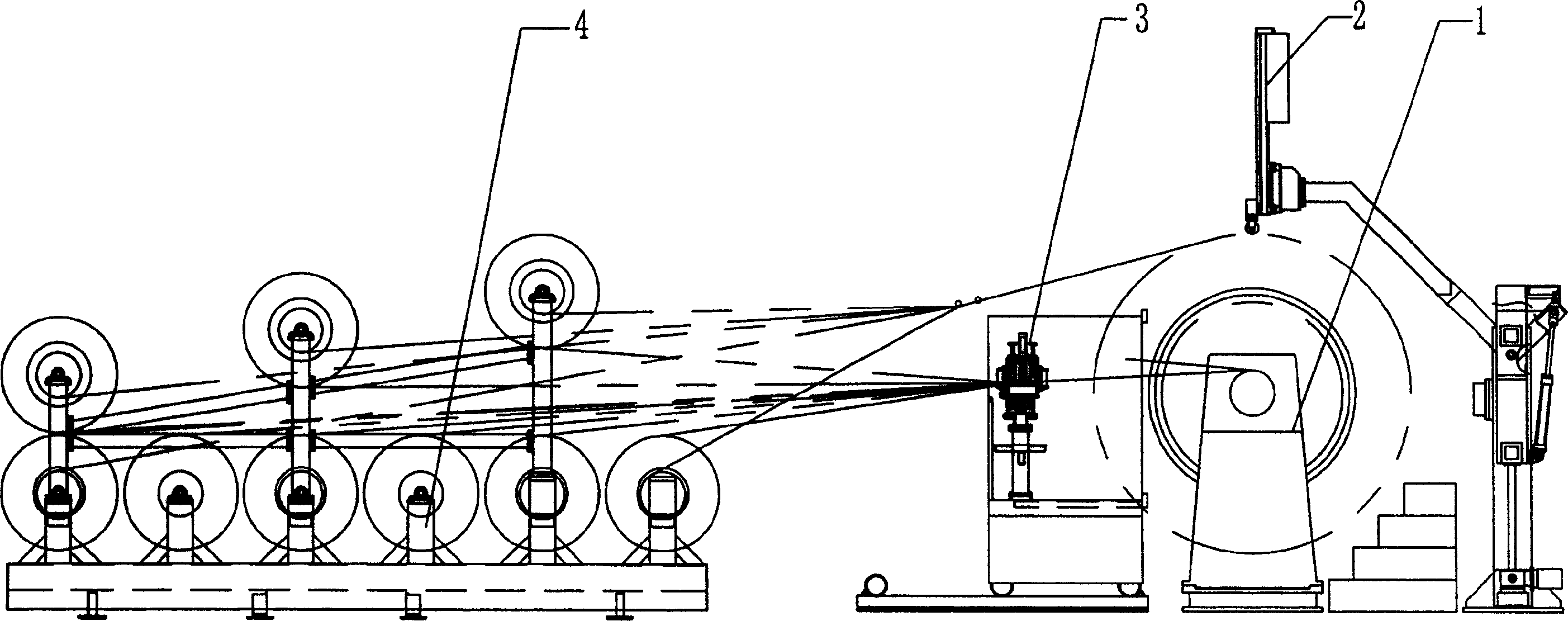

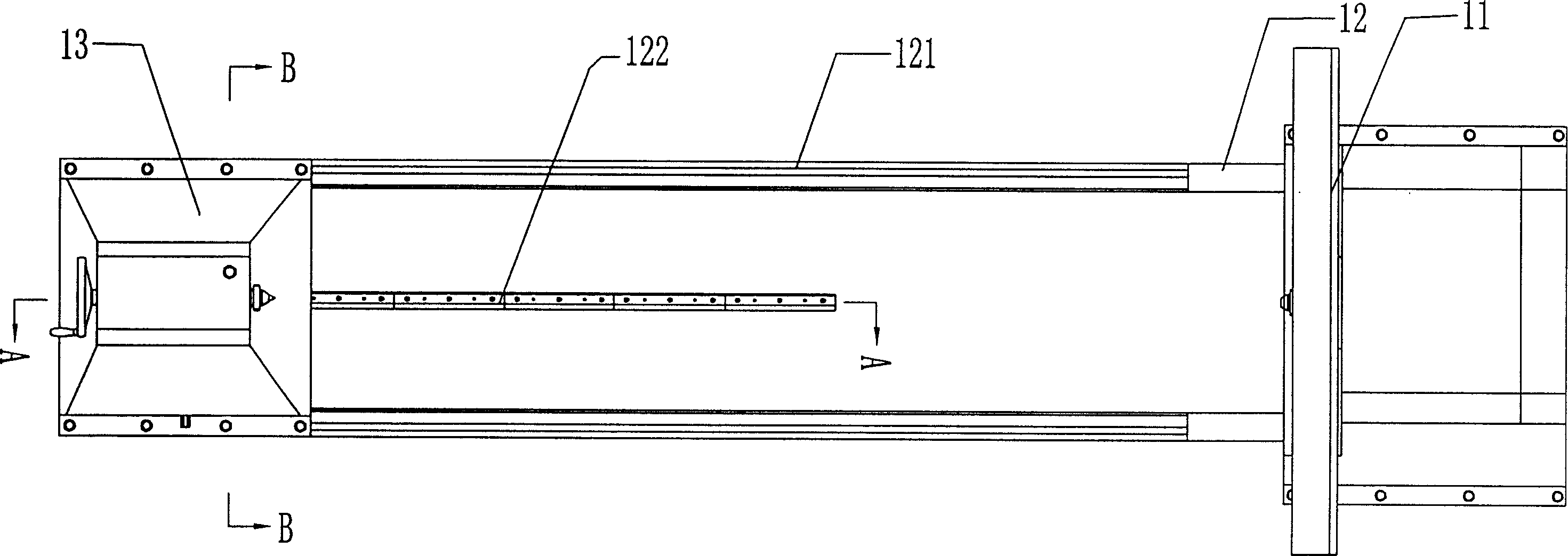

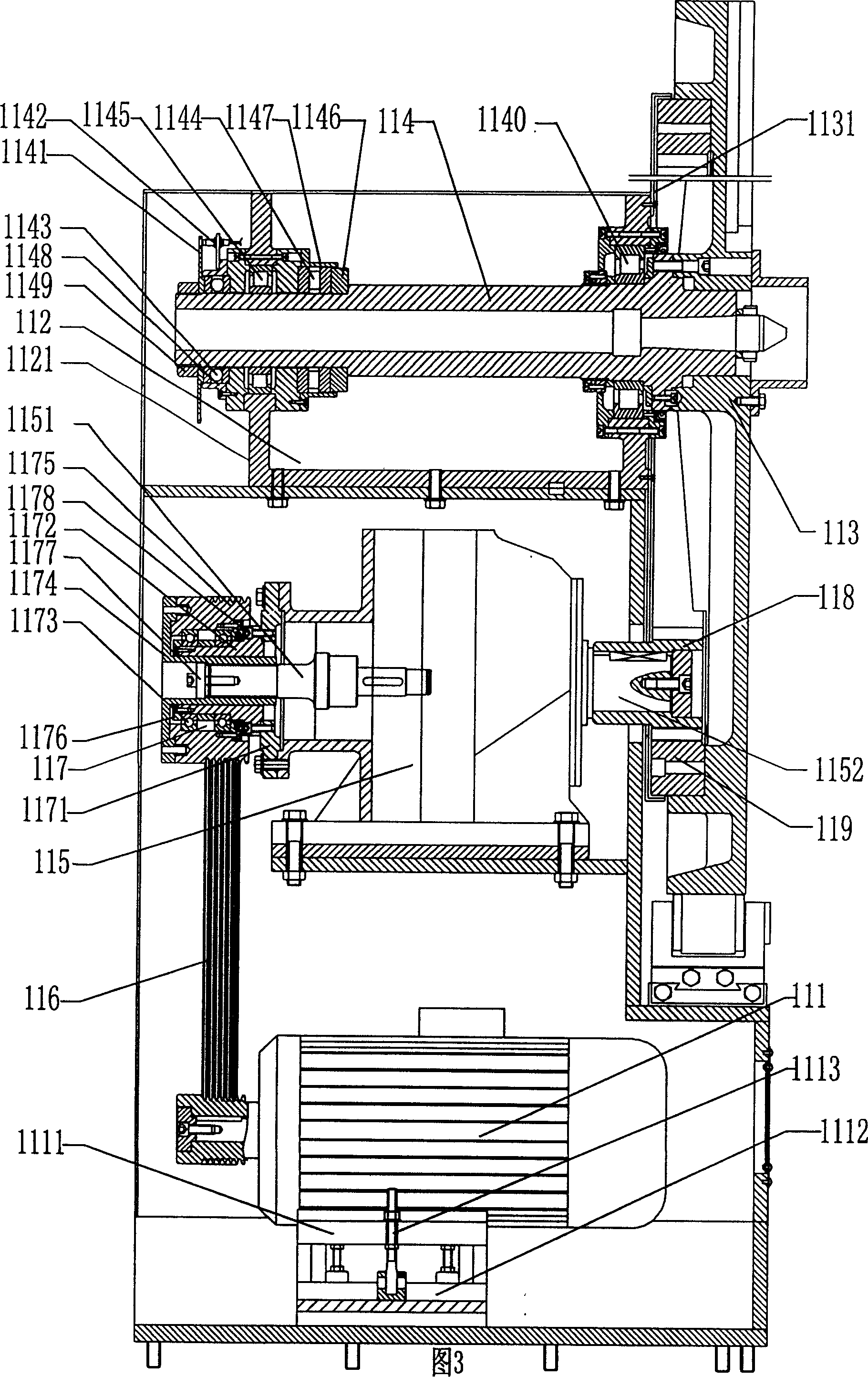

[0021] Such as figure 1 , 2 , 3, 4, 7, and 8, a new type of winding machine system, including a host 1, a wire crimping device 2, a wire branching mechanism 3, a flat car 4, and an electrical control system. The host 1 includes a headstock 11 , base 12, tailstock 13, described headstock 11 is fixed on the base 12, described headstock 11 comprises motor 111, headstock 112, faceplate 113, and described faceplate 113 is fixed on the main shaft 114 of described headstock 112 , the base 12 is provided with a guide rail 121, the tailstock 13 includes an axial travel mechanism and a jacking mechanism, a locking mechanism is provided between the tailstock 13 and the base 12, and the motor 111 is a variable frequency motor , the headstock 11 is also provided with a speed reducer 115, a transmission belt 116 is provided between the motor 111 and the speed reducer 115, and the input shaft 1151 of the speed reducer 115 is connected with the unloading mechanism 117, so The output shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com