Gas float and deposition equipment for separating solid and liquid

A technology of solid-liquid separation and air flotation, which is applied in the direction of flocculation/sedimentation water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problems of not meeting the requirements of air flotation, broken flocs, and affecting the treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

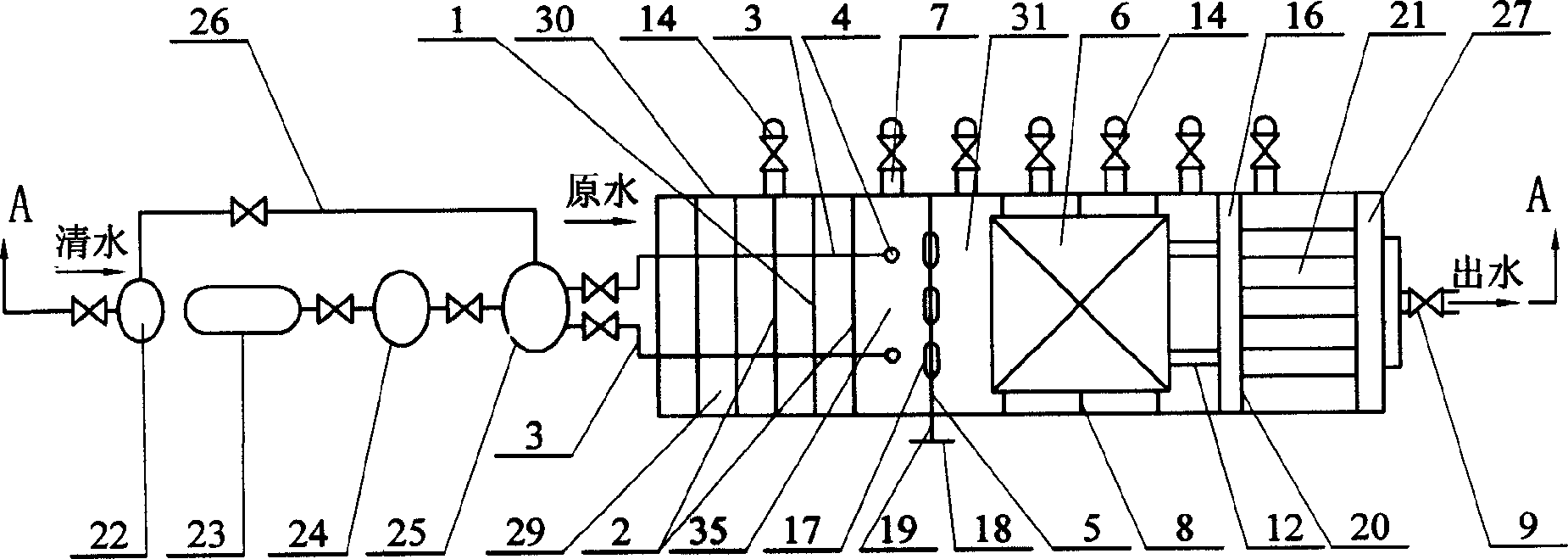

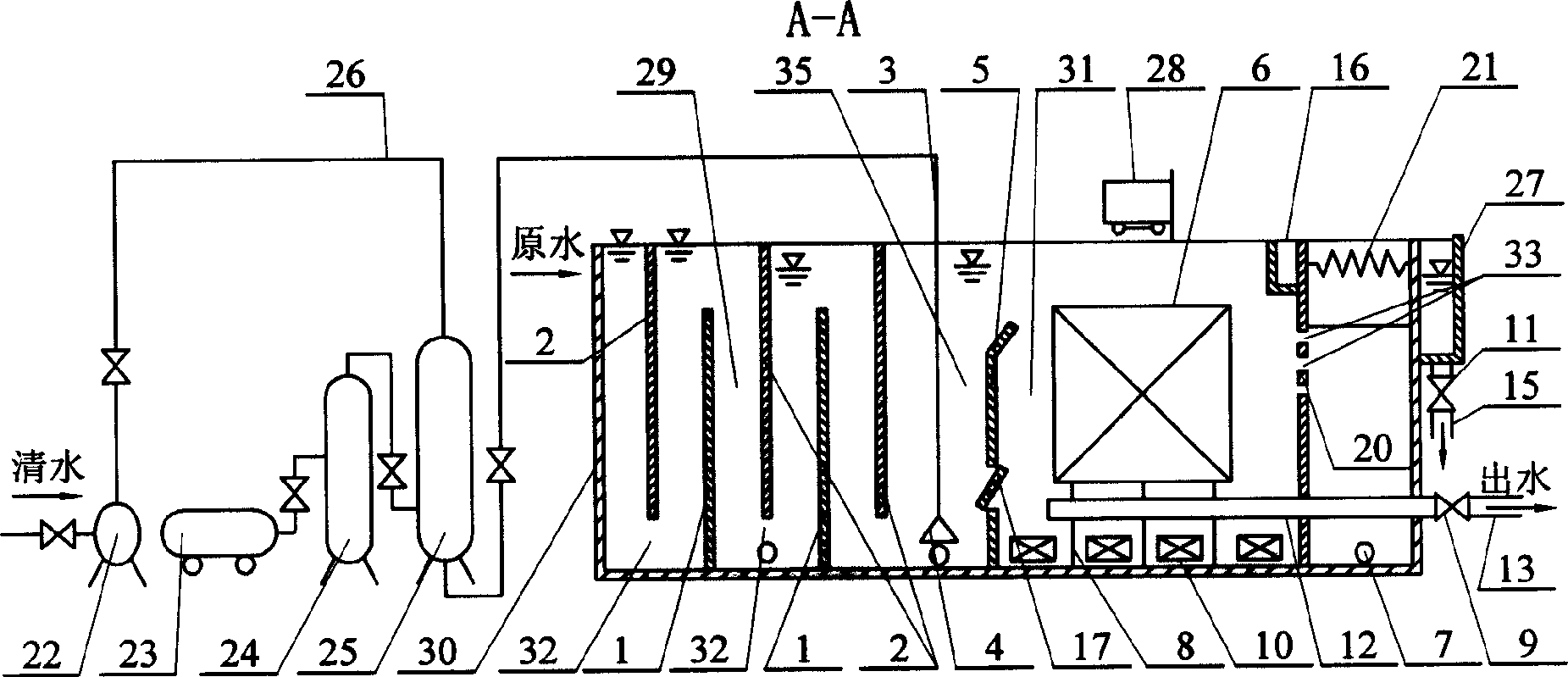

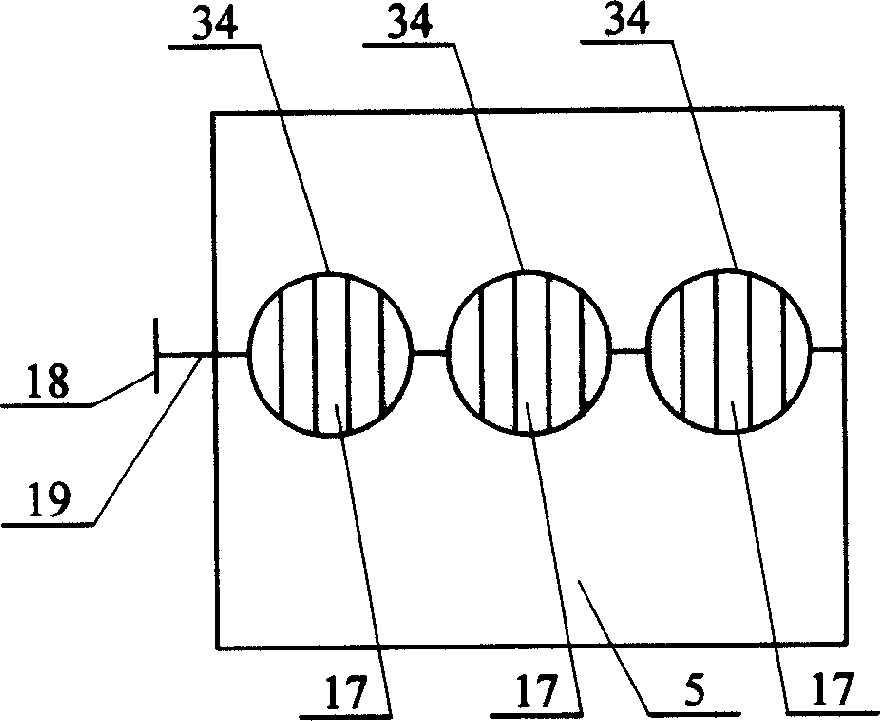

[0005] Specific implementation mode one: (see Figure 1-Figure 3 ) This embodiment consists of a partition 1, a water distribution baffle 2, a dissolved air pipe 3, a releaser 4, a contact area baffle 5, an inclined plate assembly 6, a perforated mud discharge pipe 7, a baffle 8, and an air flotation outlet valve 9. Mud scraper 10, sediment outlet valve 11, perforated water collection pipe 12, air flotation outlet pipe 13, sediment discharge valve 14, sediment outlet pipe 15, slag discharge tank 16, communication valve 17, valve hand wheel 18, connecting rod 19. Composed of perforated flower wall 20, water collection tank 21, return water pump 22, air compressor 23, air storage tank 24, dissolved air tank 25, pipeline 26, main water collection tank 27, slag scraper 28, shell 30, and contact area baffle 5 is fixed in the shell 30, the flocculation pool 29 is formed in the shell 30 on the left side of the contact area baffle plate 5, and the separation area 31 is formed in the s...

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 1 ) The difference between this embodiment and the first embodiment is that the dissolved air water pipe 3 is composed of two, and the two dissolved air water pipes 3 are arranged in parallel. Other composition and connection relationship with

[0007] The specific embodiment one is the same.

[0008] Working principle: When the raw water has low turbidity, low temperature, low turbidity, high algae, and high color, switch to the air flotation process.

[0009] (1) Open the sediment discharge valve 47, start the mud scraper 10 to scrape and discharge mud, and close the sediment outlet valve 11 at the same time to stop the water outlet. (2) After the settled sludge is determined according to the water quality of the sludge discharge, close the communication valve 17 on the baffle plate 5 in the contact area, start the backflow water pump 22 and the air compressor 23, and when the dissolved air pressure reaches, pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com