Combining method for measuring fiber profile and mechanics behavior and equipment

A measurement method and optical measurement technology, which can be used in measurement devices, material analysis by optical means, and testing of material strength by applying a stable torsion force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

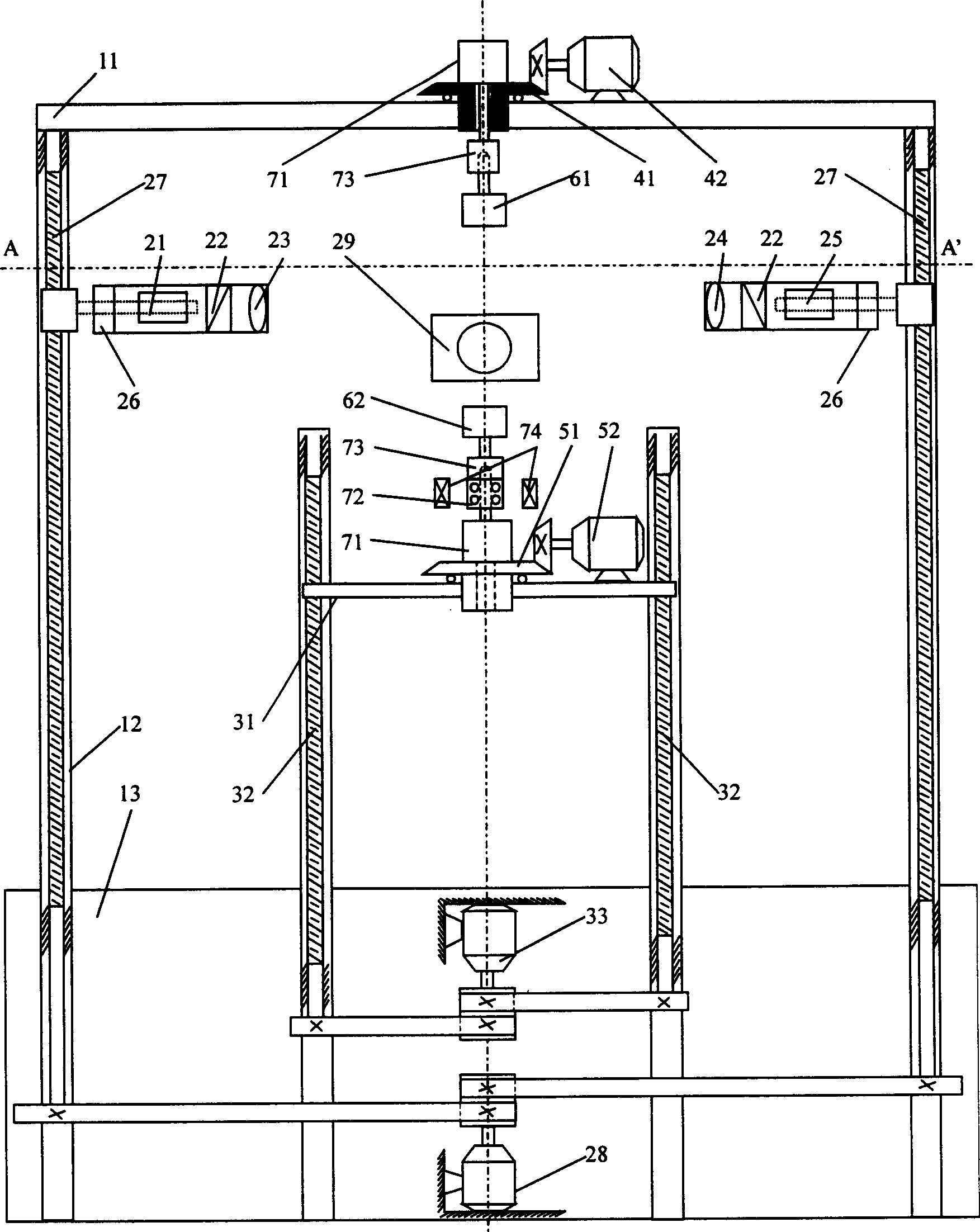

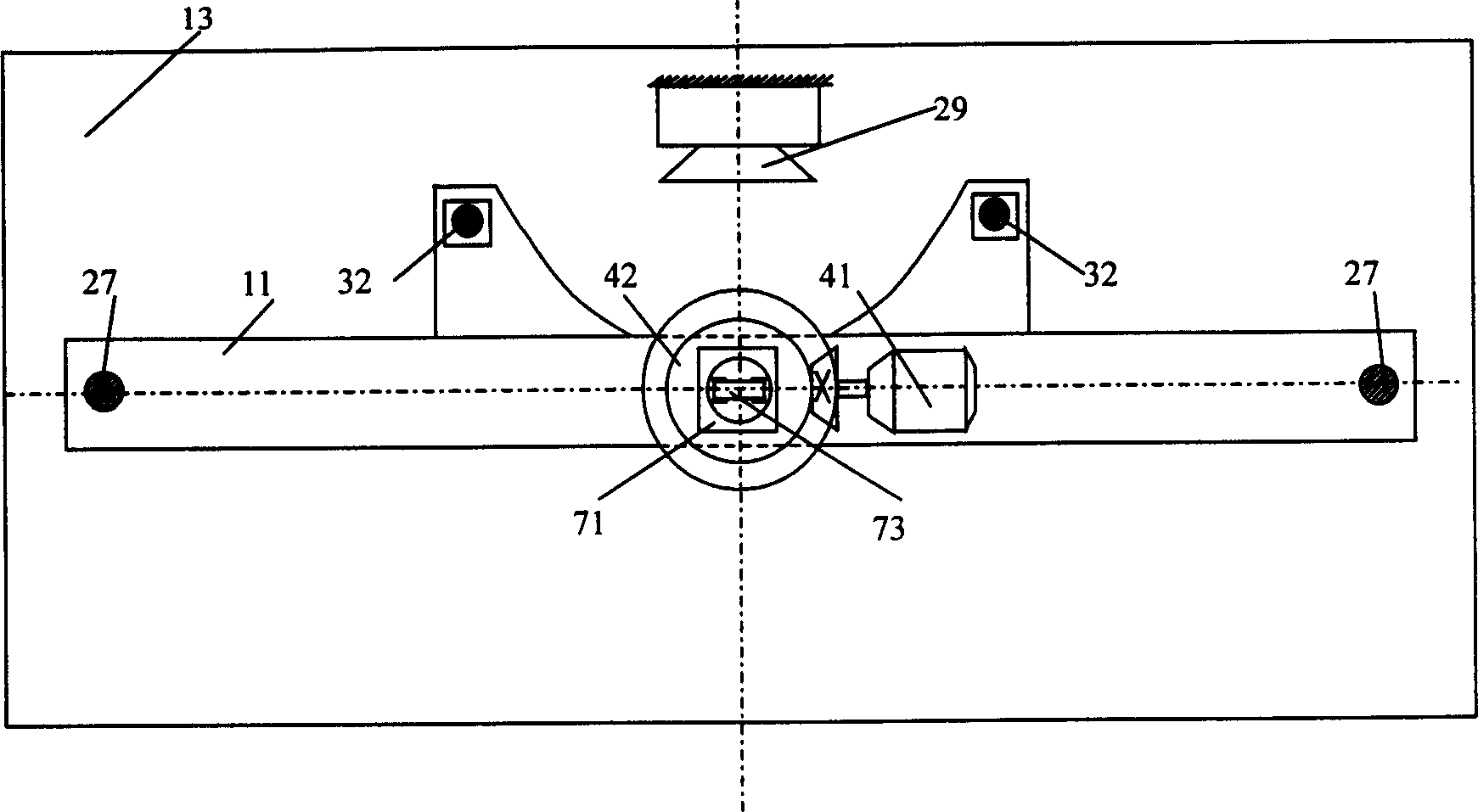

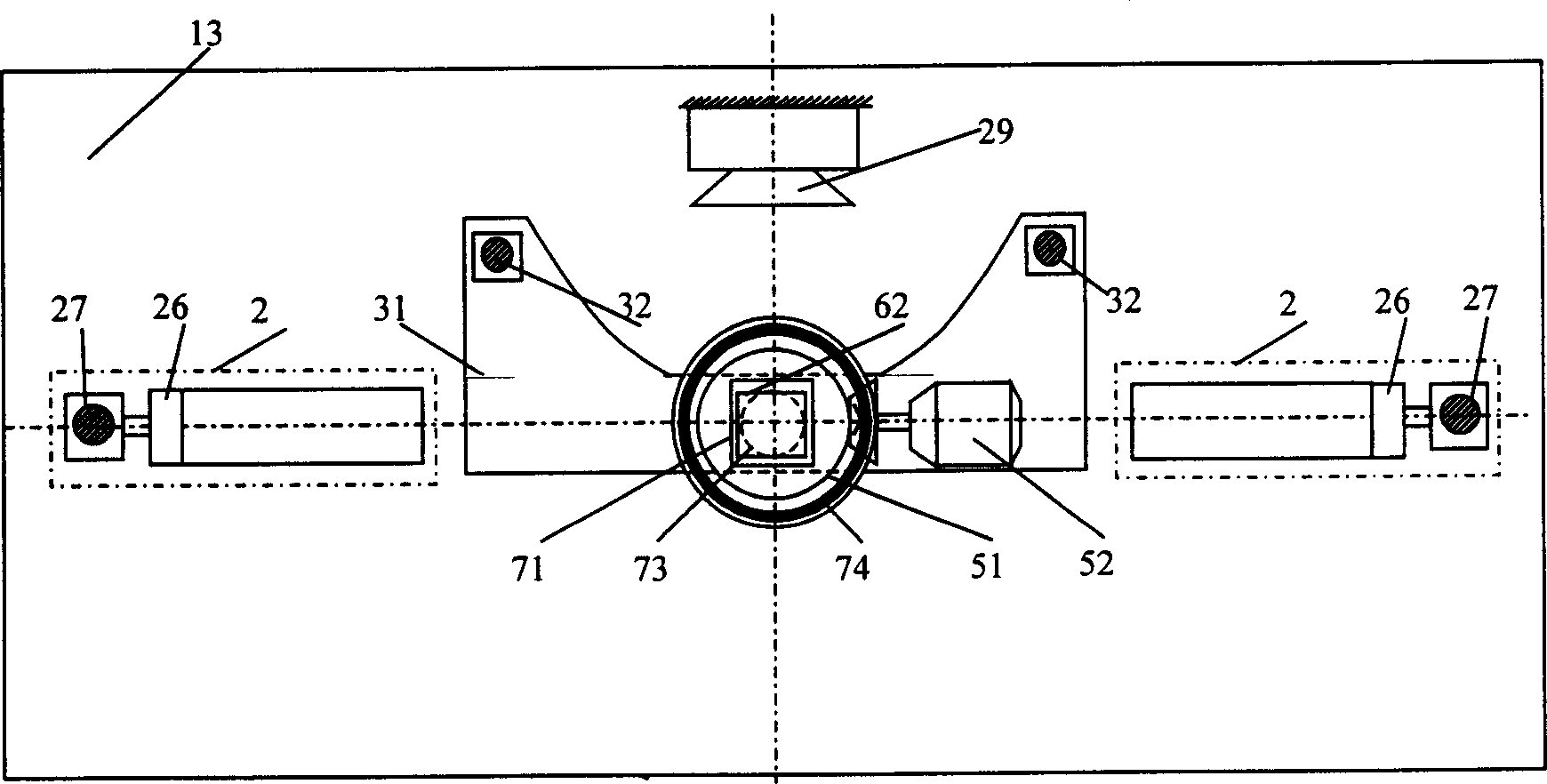

[0043] In Example 1, the force-displacement characteristic curve and parameters were obtained.

[0044] According to the measurement requirements, clamp a certain length of fibrous material sample to the upper holder 61 and the lower holder 61; the stepping motor 33 rotates the screw 32 to drive the moving beam 31 to move down vertically to apply a predetermined tension to the sample ; The stepping motor 52 rotates the rotating disk 51 to drive the lower clamp 62 to rotate to a certain angle, and there are two states: one is that the force sensor 71 connected to the lower clamp 62 increases inductively and rotates in the opposite direction; If the force sensor 71 connected to the lower gripper 62 becomes smaller, the moving beam 31 moves down vertically until the force sensor 71 connected to the lower gripper 62 should receive the initial force; then, the lower gripper The device 62 continues to rotate, and the moving beam 31 continues to move vertically downwards;...

Embodiment 2

[0064] Example 2, the results and cross-sections measured at different angles.

[0065] According to the measurement requirements, clamp the polyester fiber sample of approximately elliptical cross-section with a cut length of 50mm in the upper holder 61 and the lower holder 61; according to the measurement procedure of Example 1, the sample is completely untwisted to achieve natural Straightened state; align the optical axis center of the optical measuring mechanism 2 with the fiber sample, automatically adjust the focus and obtain the cross-sectional profile of the fiber sample at this position, the upper holder 61 and the lower holder 62 rotate the fiber sample synchronously, when The cross-sectional profile width at this location changes from small to large, and then from large to small, then this profile is the long axis of the ellipse section. The short axis of the elliptical section; then align the center of the optical axis of the optical measurement mecha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com