Control system for multi robot carrying based on wireless network

A wireless network, multi-robot technology, applied in control/regulation systems, non-electric variable control, position/direction control, etc., to achieve high real-time performance, easy information automation management, and remote monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

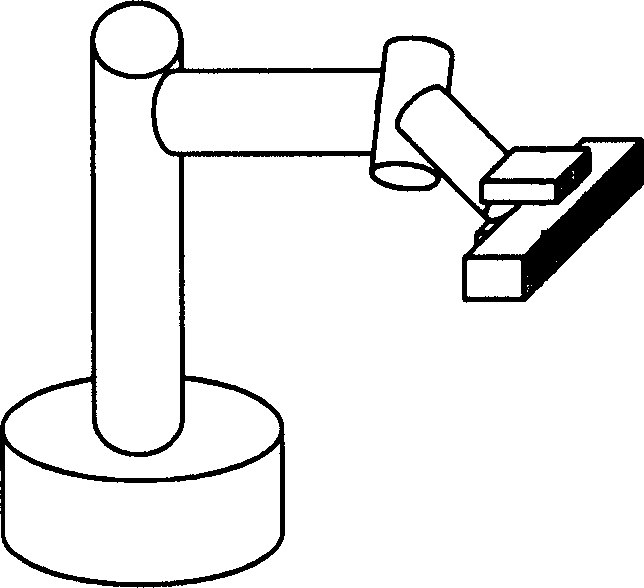

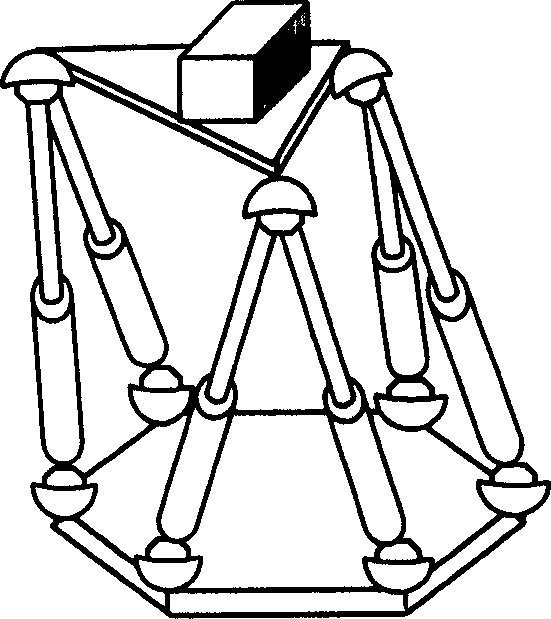

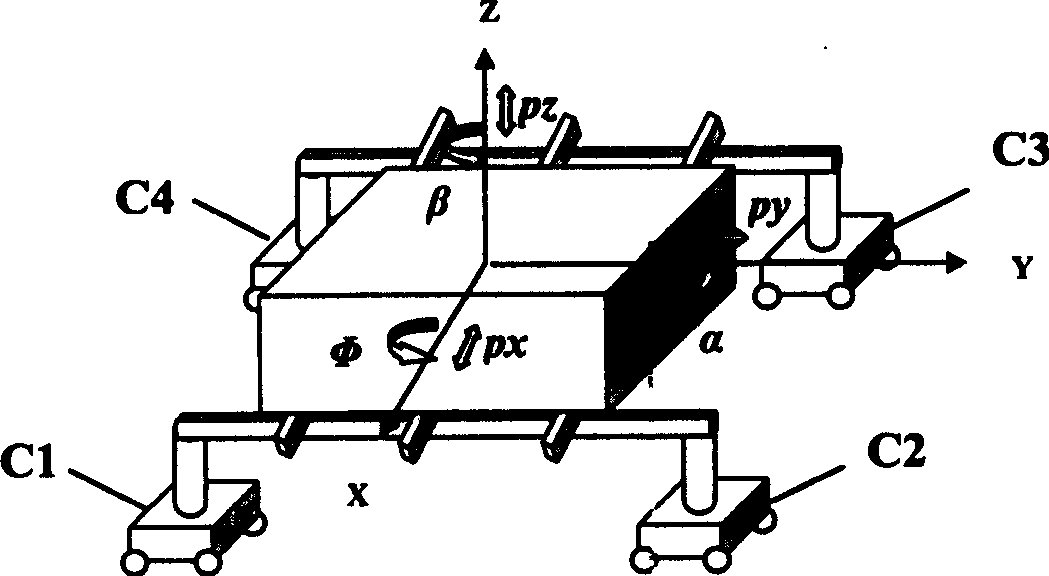

[0020] In the example, press Figure 4 A 6-degree-of-freedom multi-robot handling platform composed of four CAS-II 3-degree-of-freedom mobile robots was built. Figure 5 and Figure 6 The control system shown realizes the control of the transport platform. in, Figure 5 Industrial computer I1 adopts ADVANTECH-610, which is equipped with Windows 2000 operating system and upper computer application software; wireless network card R1 adopts Tsinghua Tongfang TFW1200-PCI; wireless bridge AP adopts Tsinghua Tongfang TFW2000. Figure 6 The medium PC / 104 unit P1 adopts Advantech PCM-3345, which is equipped with RT-Linux embedded real-time operating system and lower computer application software; the wireless network card access module C1 adopts Advantech PCM-3110C; the wireless network card W1 adopts Tsinghua Tongfang TFW1000-PCMCIA; Axis control card C2 adopts PMAC2A-PC / 104 from American Delta Tau Company; servo amplifiers A1, A2 and A3 adopt Yaskawa YASKAWACACR-SR15SZ1SD-Y214 ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com