Minisize chemical propeller with pressure sensor

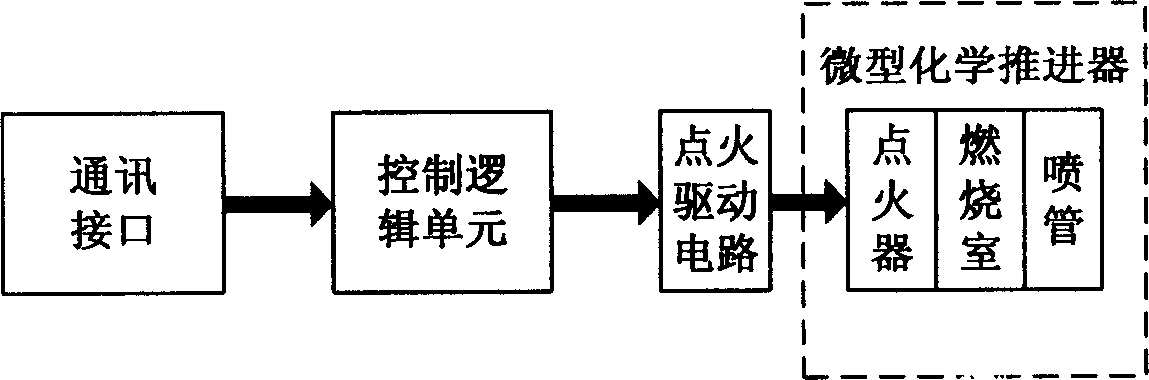

A pressure sensor and thruster technology, applied in the field of micro-propulsion technology, can solve problems such as the inability of feedback control of MEMS chemical thrusters, and achieve the effects of eliminating uneven thrust and impulse, short ignition delay time, and low ignition power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

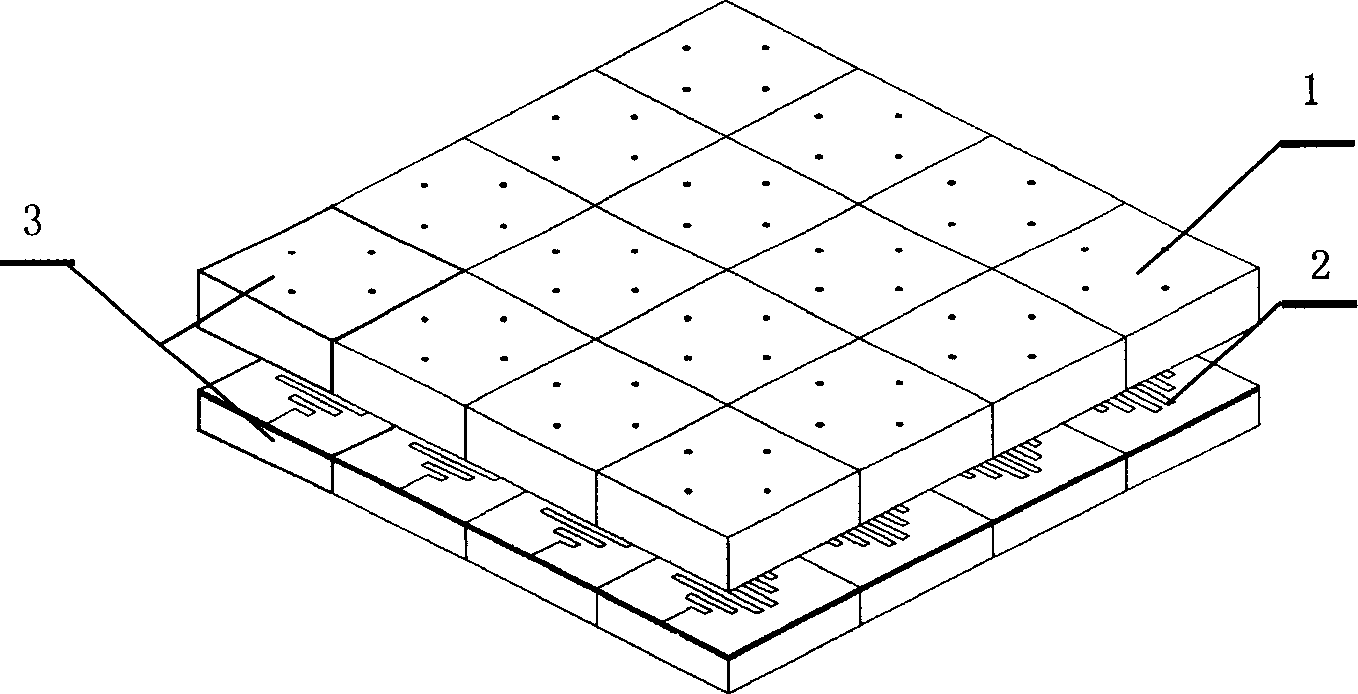

[0031] 1. Overall and basic unit structure

[0032] figure 2 Shown is the overall structure of the thruster, which is formed by bonding the upper silicon wafer 1 and the lower silicon wafer 2. It is a periodic array of a series of basic propulsion units 3. The size of the array can be changed according to the actual use requirements. Craft level limitation. In order to prevent the chain explosion of adjacent units from damaging the entire propeller due to the explosion of one unit, the grouping array layout of propulsion units is adopted.

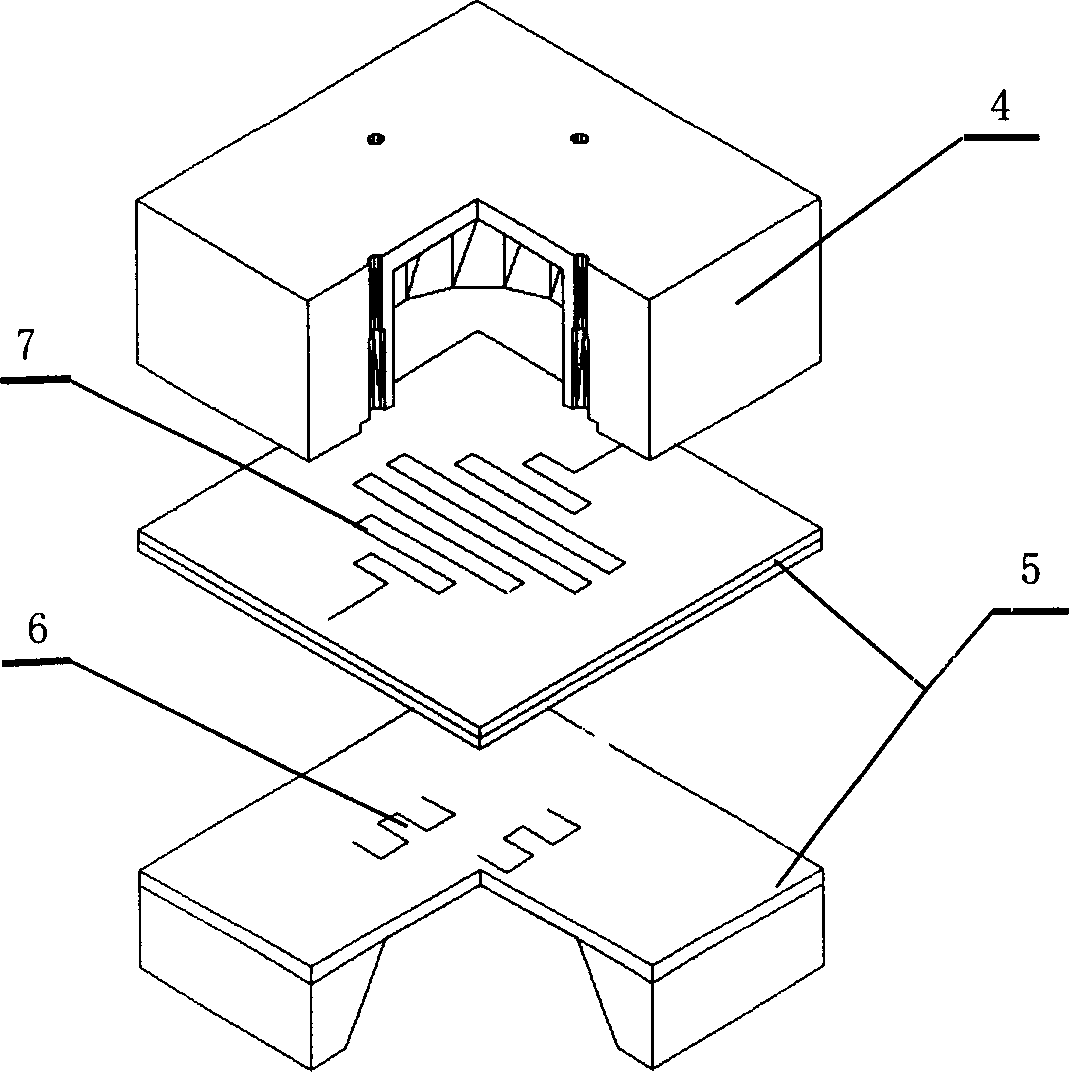

[0033] Such as image 3 As shown, the upper part 4 of the basic propulsion unit 3 integrates the combustion chamber, the ignition charge chamber and the nozzle. The nozzles are uniformly distributed around the combustion chamber and are rotationally symmetrical with respect to the central axis of the combustion chamber. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com