Double monochromatic spectroscopic device

一种分光镜、单色的技术,应用在光学元件、光谱测定法/分光光度测定法/单色器、仪器等方向,能够解决影响分光镜器件性能、没有讲述波长的校准等问题,达到时间和劳动量缩短、低成本、提高生产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

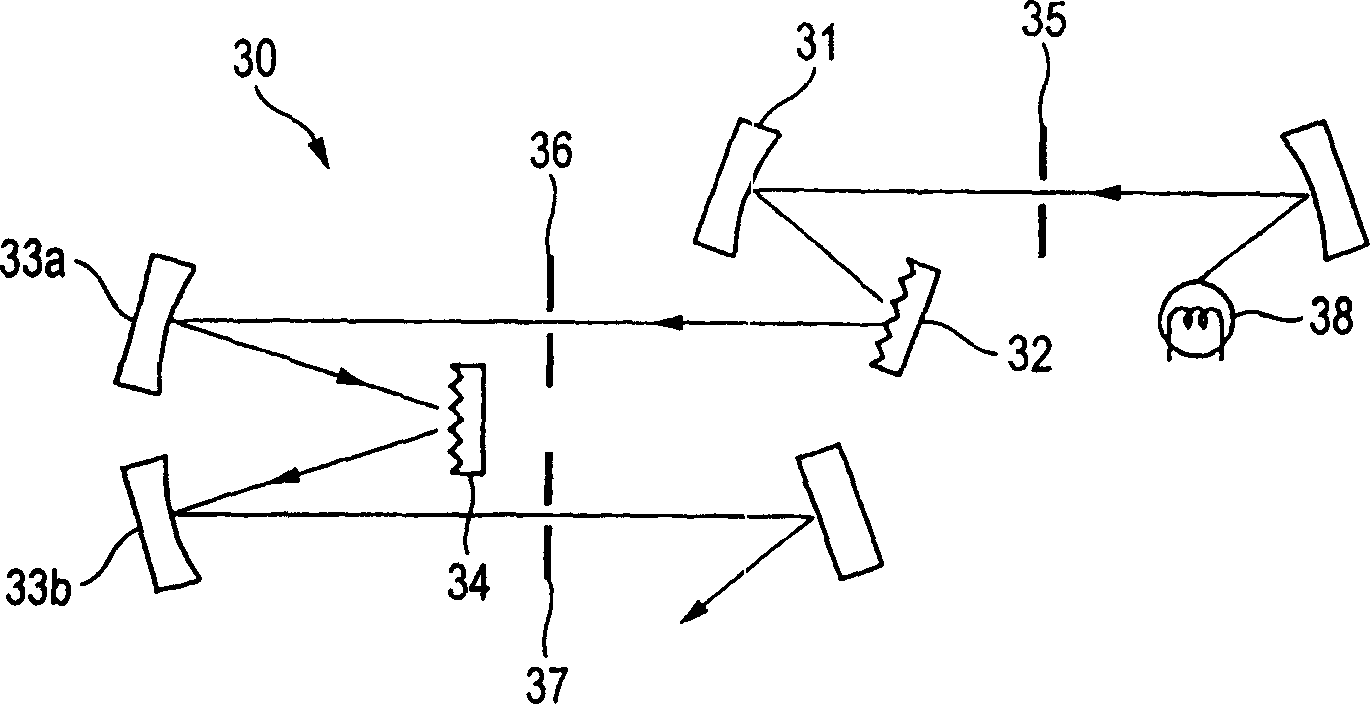

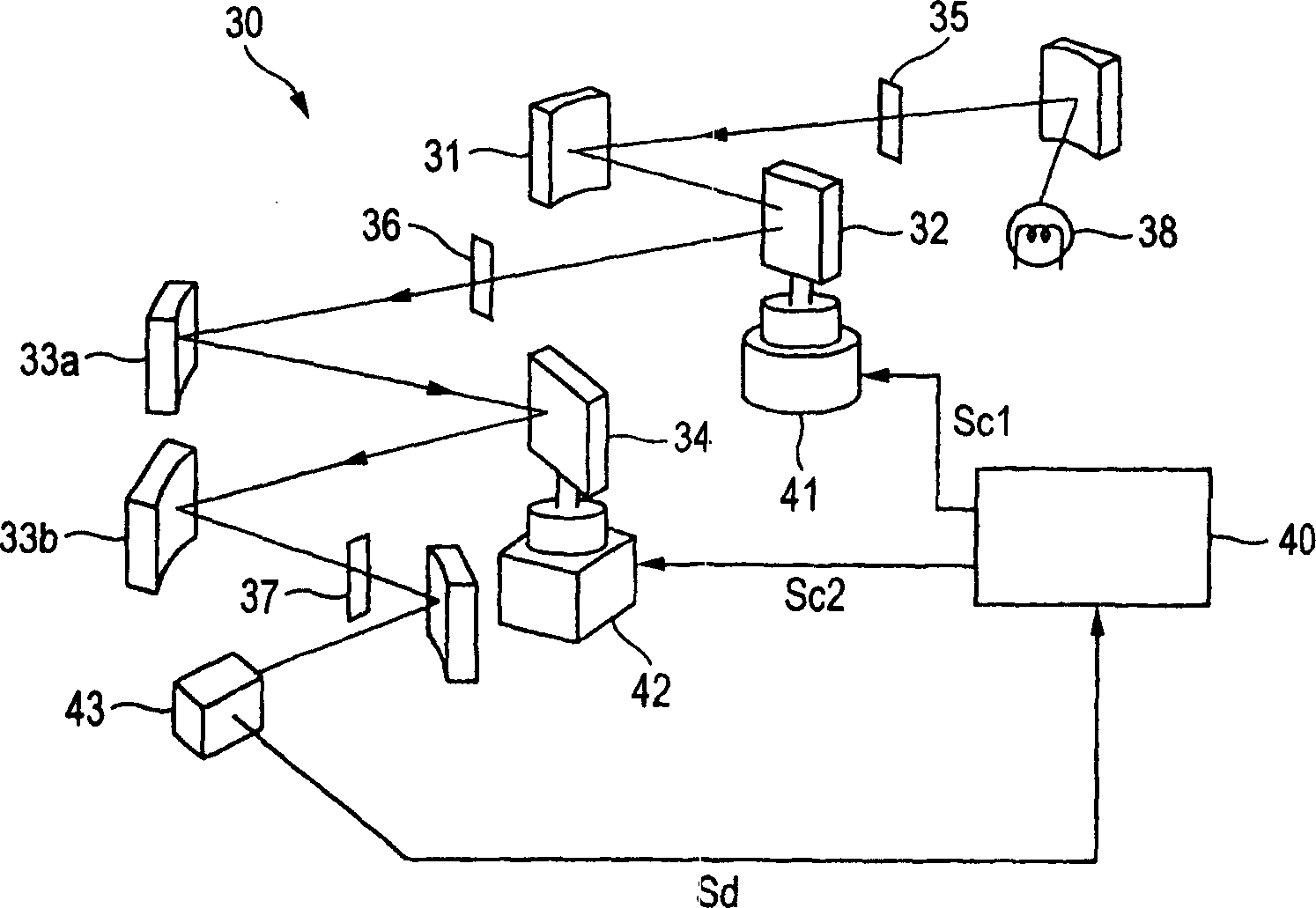

[0028] Figure 1A It is an optical system diagram of a double monochromatic beam splitter device of an embodiment of the present invention, Figure 1B is a perspective view of the arrangement of the main components.

[0029] from Figure 1A As can be seen in the figure, the beam splitter device 30 according to this embodiment includes a pre beam splitter and a main beam splitter. The front beam splitter is a Monk-Gyreeson type beam splitter, including a concave mirror 31 and a concave diffraction grating 32 . The main beam splitter is a Czerny-Turner beam splitter, including two concave mirrors 33a, 33b and a plane diffraction grating 34 . The entrance slit 35 is provided on the light incident side of the diffraction grating 32 of the pre-beam splitter. A middle slit 36 (also used as an entrance slit of the main beam splitter) is provided on the light exit side of the diffraction grating 32 of the front beam splitter. The exit slit 15 is provided on the light exit side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com