Optical pickup

An optical pickup and light splitting technology, which is applied in the direction of instruments, beam reproduction, optical recording heads, etc., can solve the problems of increasing the number of polarization splitting elements, difference in response performance, increase in consumed electric power, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Referring now to the accompanying drawings, preferred embodiments of the present invention will be described below.

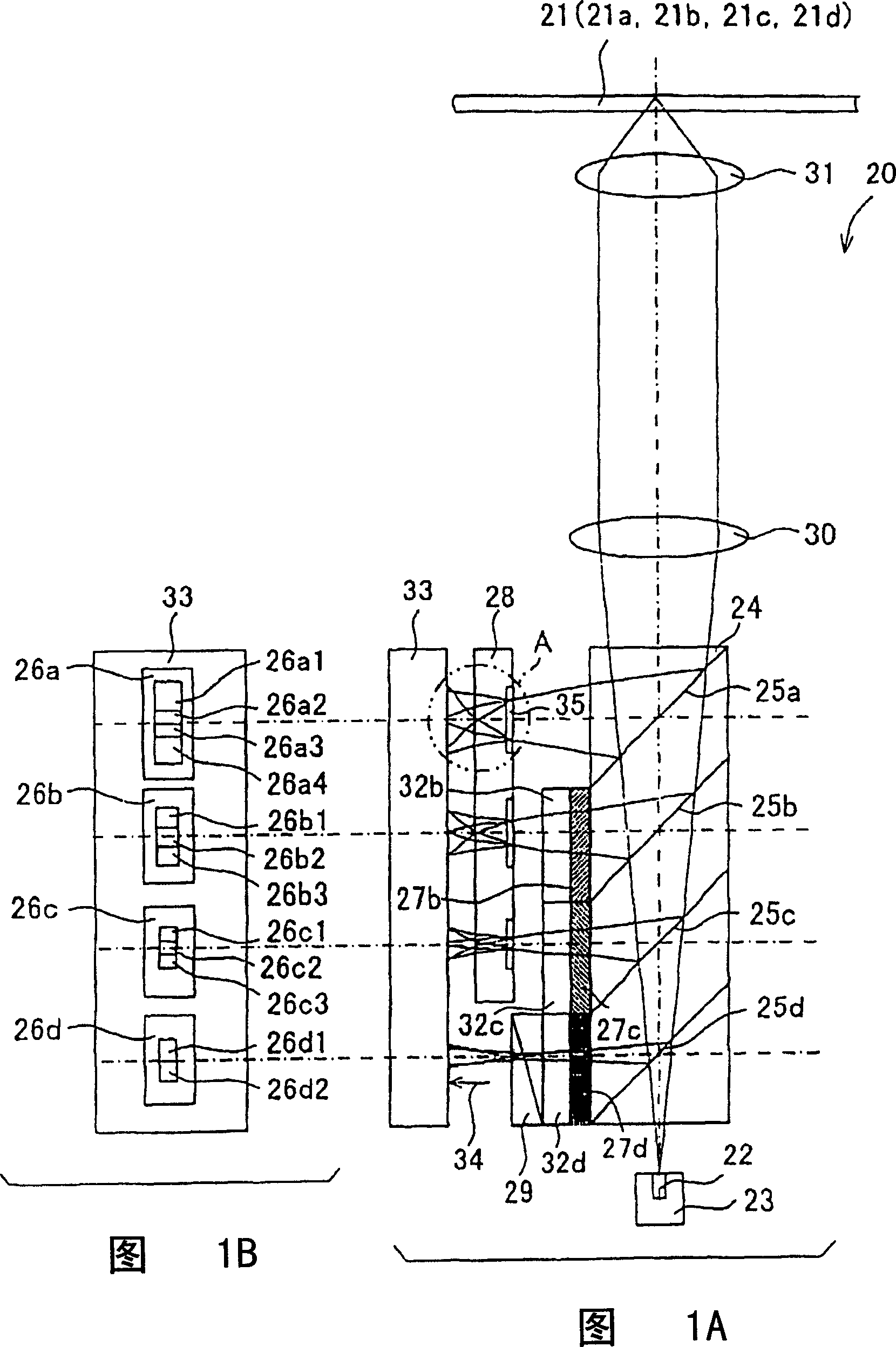

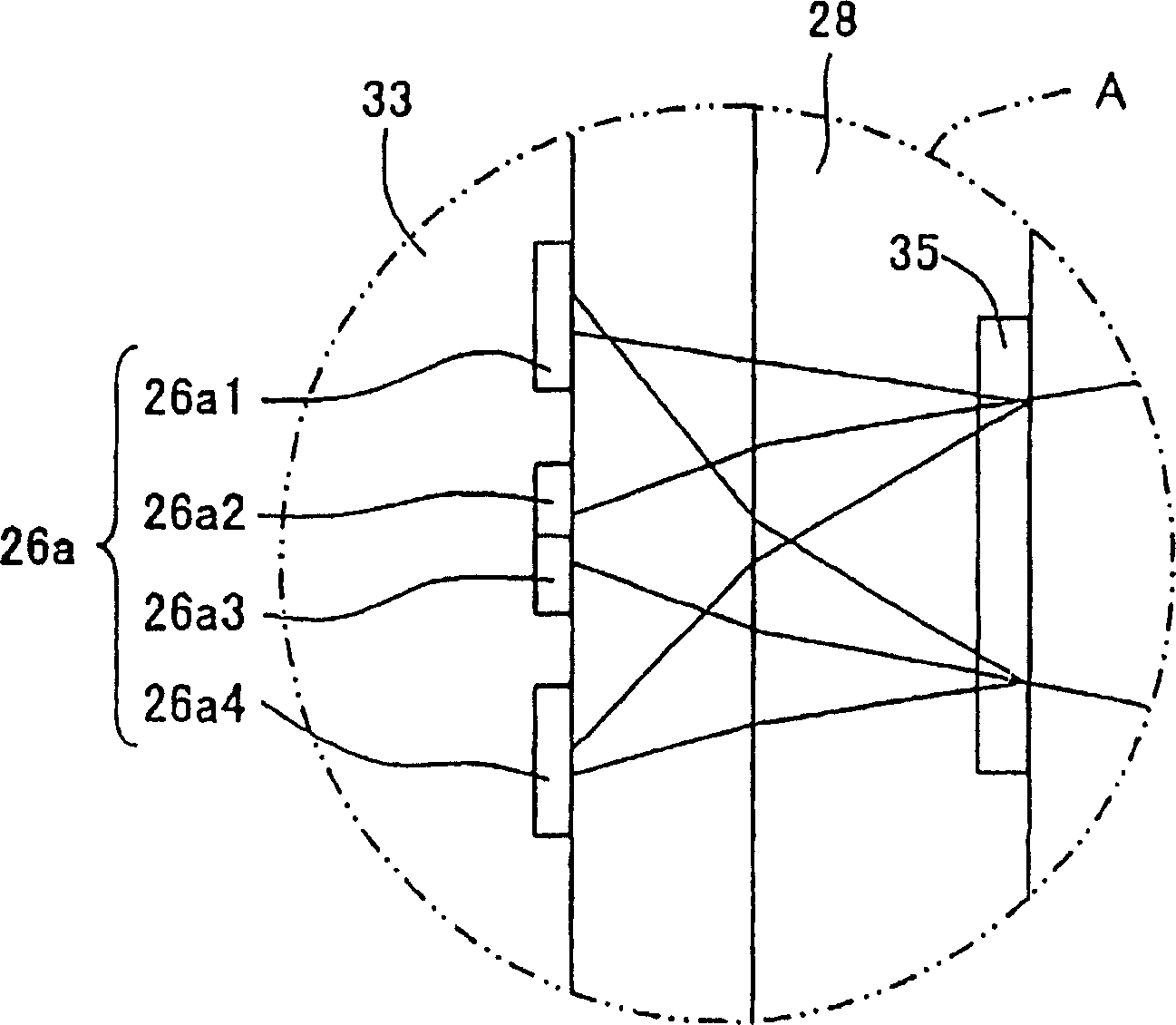

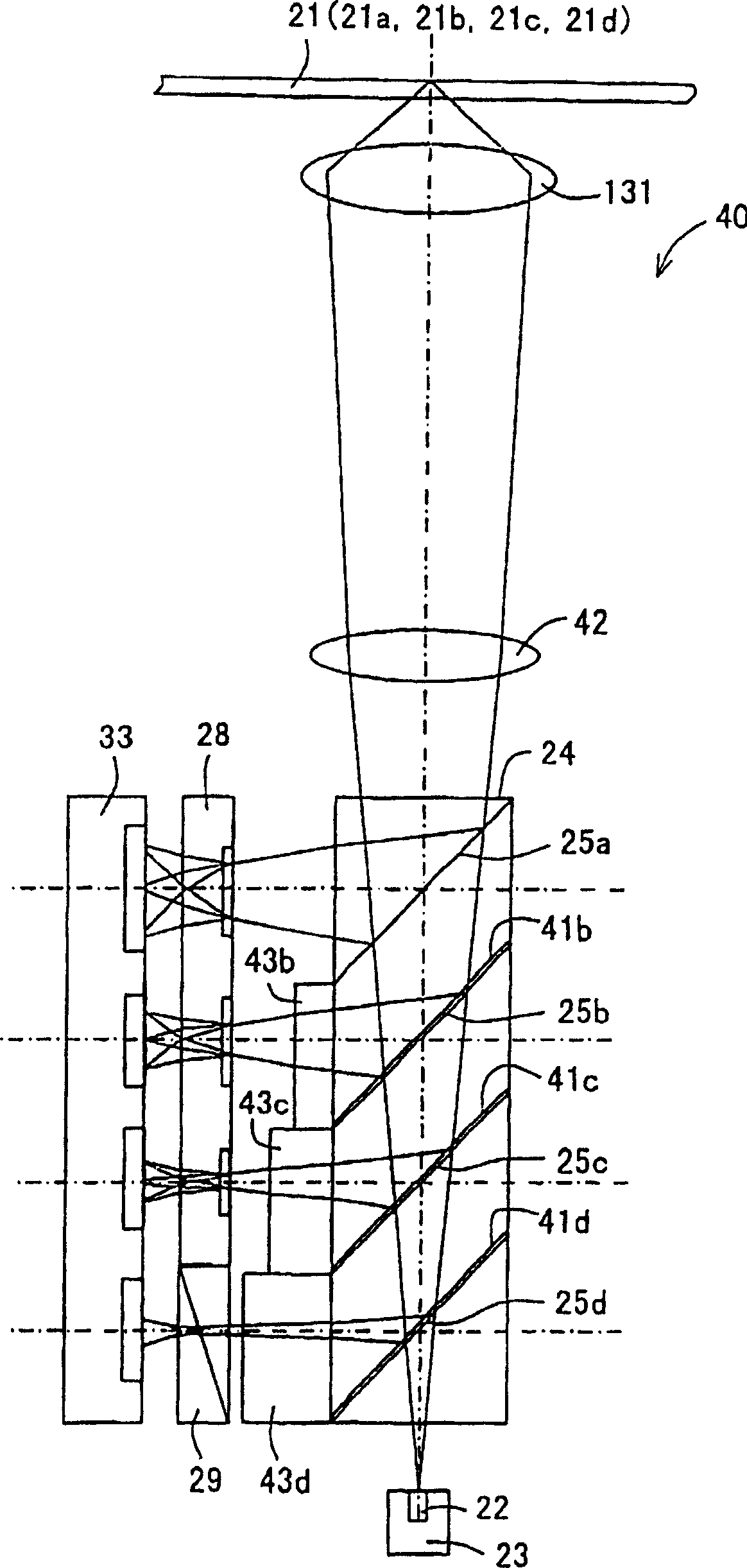

[0064] FIG. 1A is a simplified system diagram showing the structure of an optical pickup 20 according to a first embodiment of the present invention. The optical pickup 20 is a device for recording information and / or reproducing information on and / or from a plurality of (in this embodiment, four kinds of 21a, 21b, 21c and 21d) magneto-optical recording media 21, the magneto-optical recording media 21 has an information recording layer composed of a multi-layer film, and in which phase differences between polarized light beams generated at the time of signal reproduction are different from each other.

[0065]The optical pickup 20 includes a light source 22, a subassembly stage 23, a light splitting element 24, four groups of light receiving parts 26a, 26b, 26c and 26d, three phase compensating devices 27b, 27c and 27d, first and second two polarization s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com