Method and its device for burning mixed mud in circulating fluidized bed boiler

A technology of circulating fluidized bed and sludge, which is applied in the direction of fluidized bed combustion equipment, combustion method, combustion equipment, etc., can solve the problem of occupying a large space and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

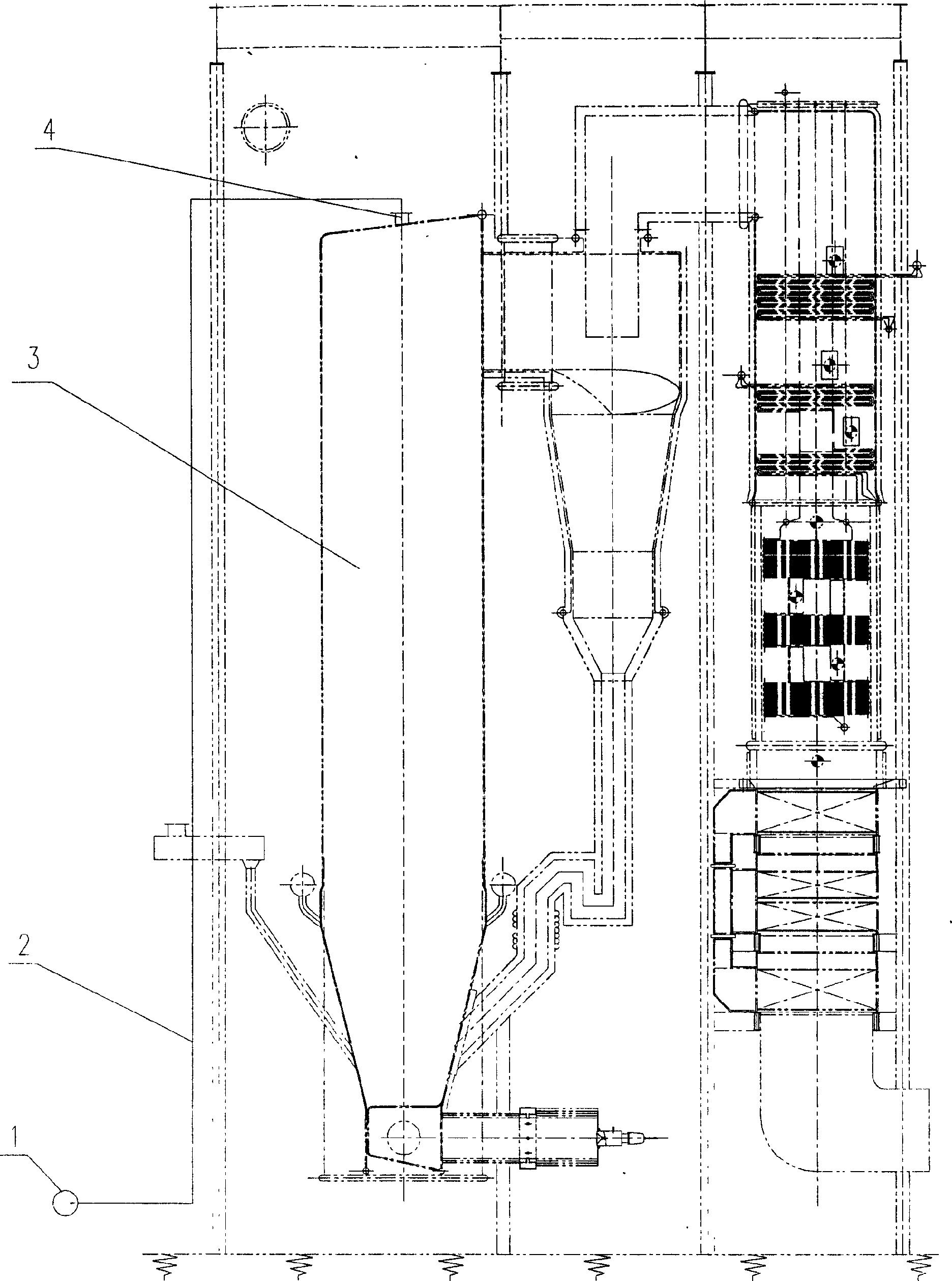

Image

Examples

Embodiment Construction

[0007] The application of this technology is to use the circulating fluidized bed boilers of thermal power plants in various regions. Through partial transformation, a sludge feed port 4 is arranged on the upper end of the circulating fluidized bed boiler 3, and the conveying pipeline 2 is connected to the sludge feed port 4. The other end of the delivery pipe 2 is connected to the output port of the sludge plunger pump 1 . While the boiler is burning coal, the sludge generated in the sewage treatment process does not need to be processed in advance, and is pumped directly to the circulating fluidized bed boiler in the upper negative pressure area of the furnace. In the upper part of the furnace, the sludge falls into the dense-phase area of the lower part of the furnace by its own weight, and is immediately surrounded by a large number of hot bed materials. The heat and mass transfer is very strong. The circulating fluidized bed boiler itself has high combustion heat inten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com