Semiconductor laser device and method of manufacturing the same

A technology of laser components and manufacturing methods, which is applied in the direction of semiconductor lasers, laser components, structures of optical waveguide semiconductors, etc. Characteristics and high-speed response characteristics, small threshold current, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Next, a semiconductor laser device according to an embodiment of the present invention will be described with reference to the drawings. In addition, although the structure and effect of the present invention have been described in more detail, the present invention is not limited to the following embodiments, and it is of course possible to add modifications within the scope of the purpose described above and below, all of which include Within the technical scope of the present invention.

[0055] (Embodiment 1)

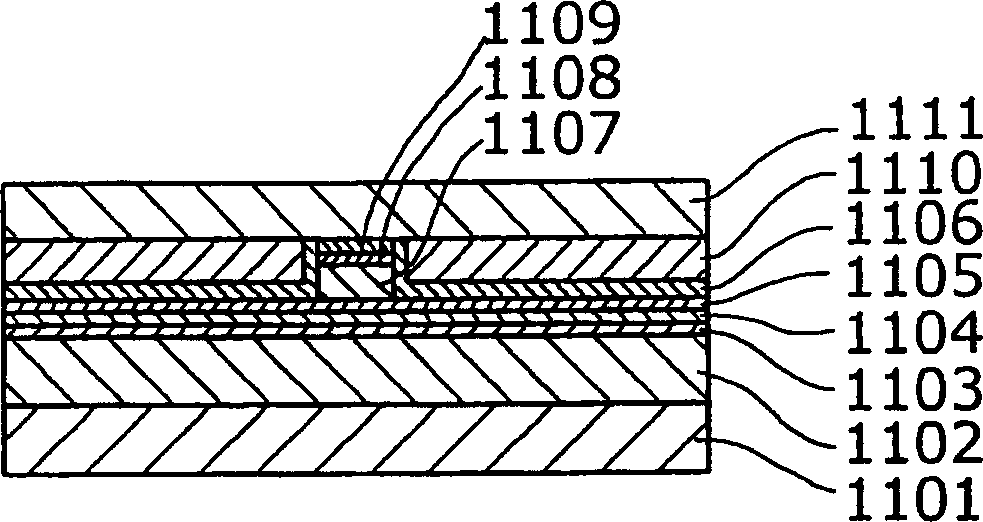

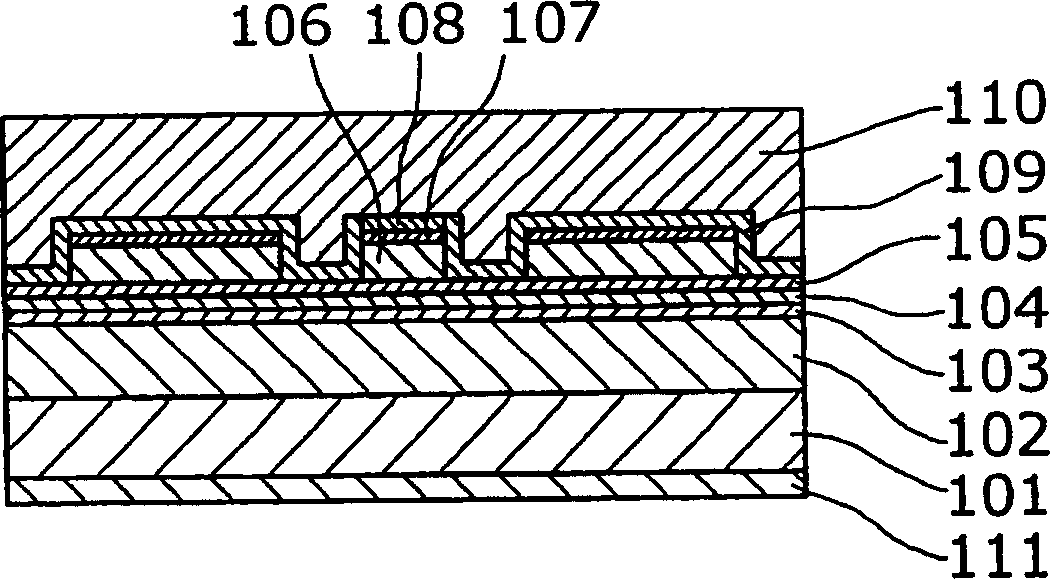

[0056] image 3 It is a cross-sectional view showing the structure of the semiconductor laser element of the first embodiment.

[0057] The semiconductor laser element of the present embodiment is a ridge-shaped semiconductor laser element, and in this semiconductor laser element, the n-type GaAs substrate 101 is sequentially stacked with 1×1018 cm -3 The n-type AlGaInP cladding layer 102 with a film thickness of 2 μm and the non-doped quantum well active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com