Processing method of deep trough ball bearig ball sbaped pocket hole cage

A technology for deep groove ball bearings and processing methods, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of wear resistance, poor impact resistance, poor dimensional stability, poor heat resistance, etc., and achieve improved processing Accuracy, improved lubricating performance, low wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

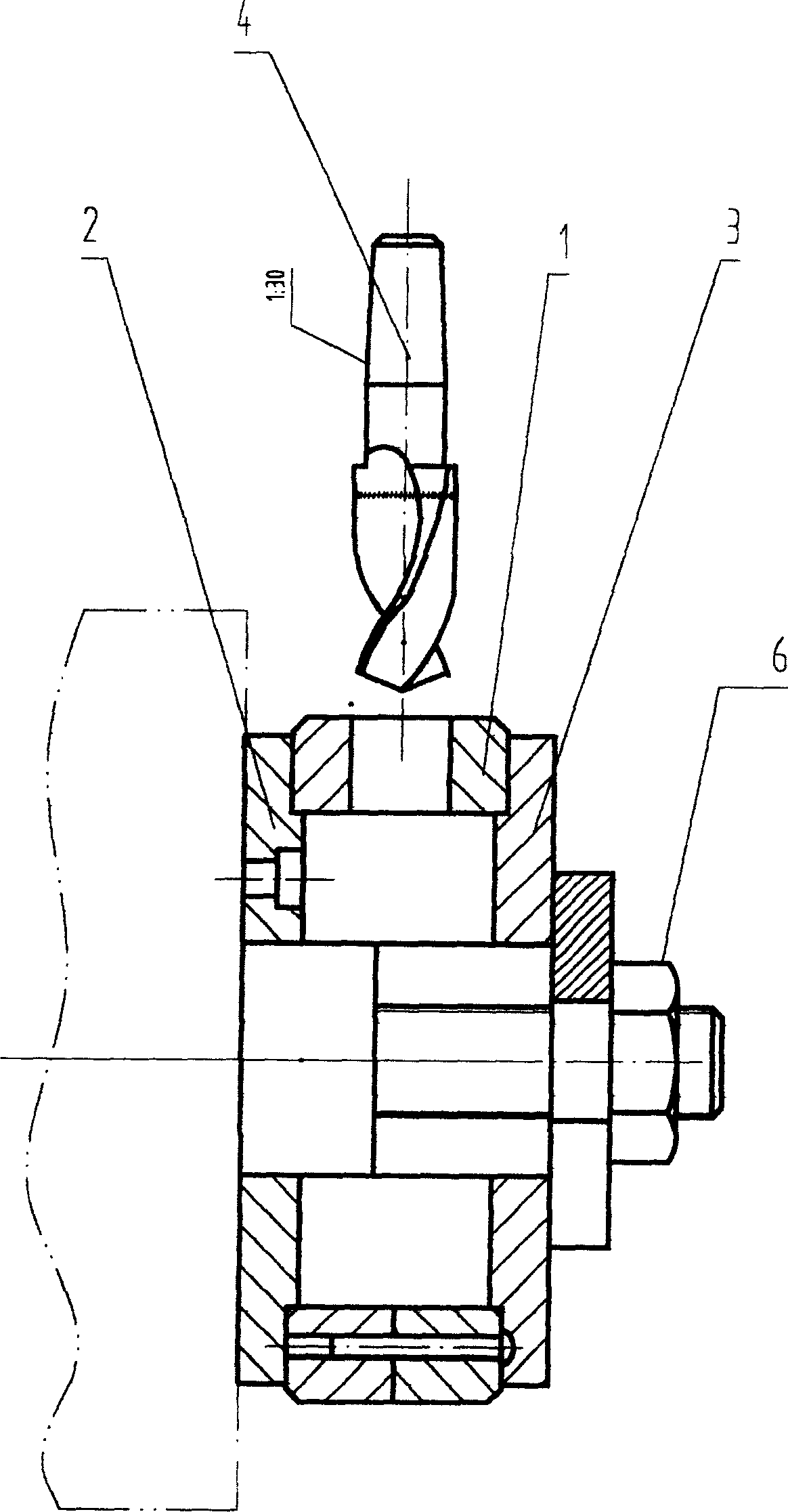

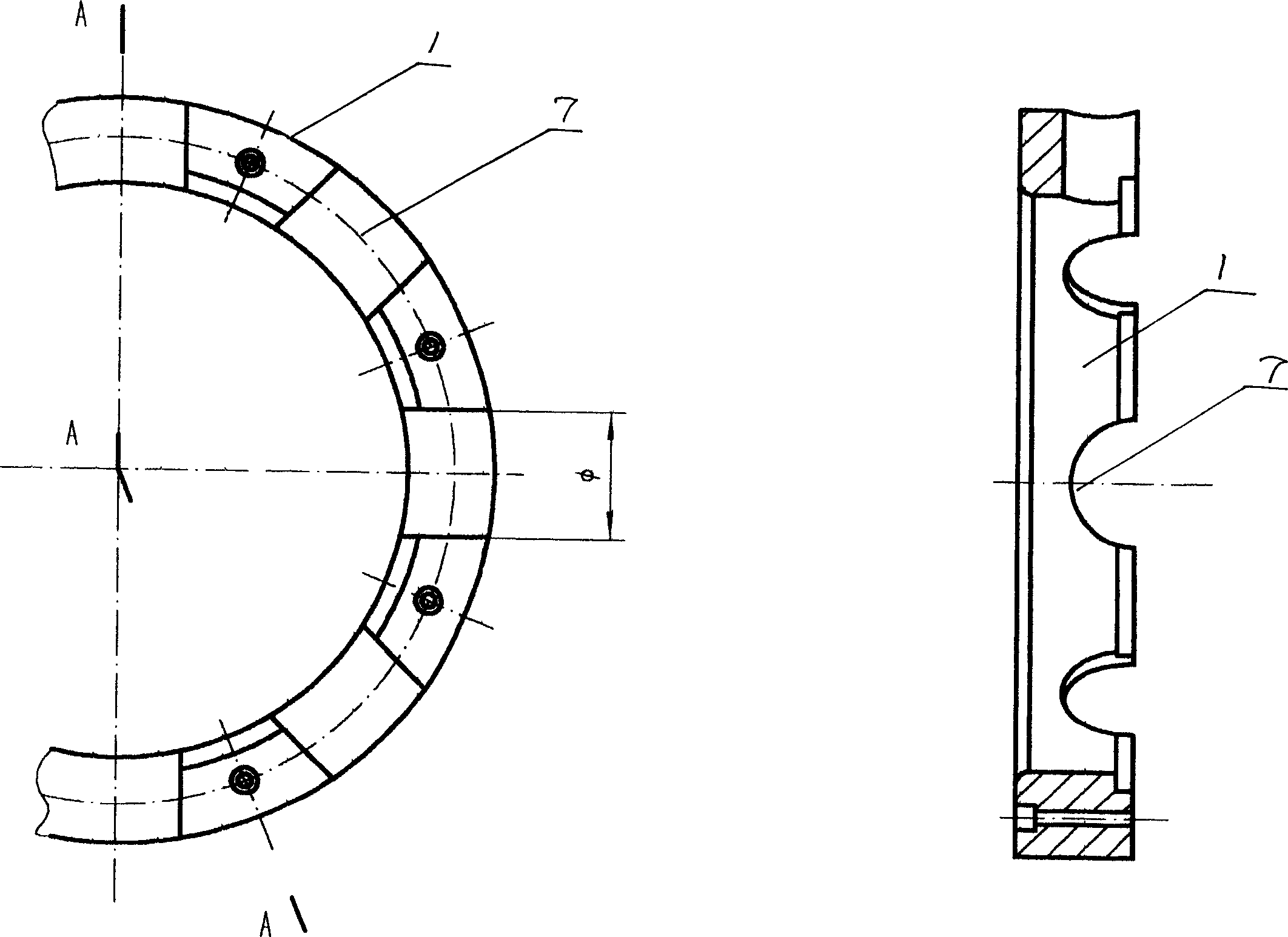

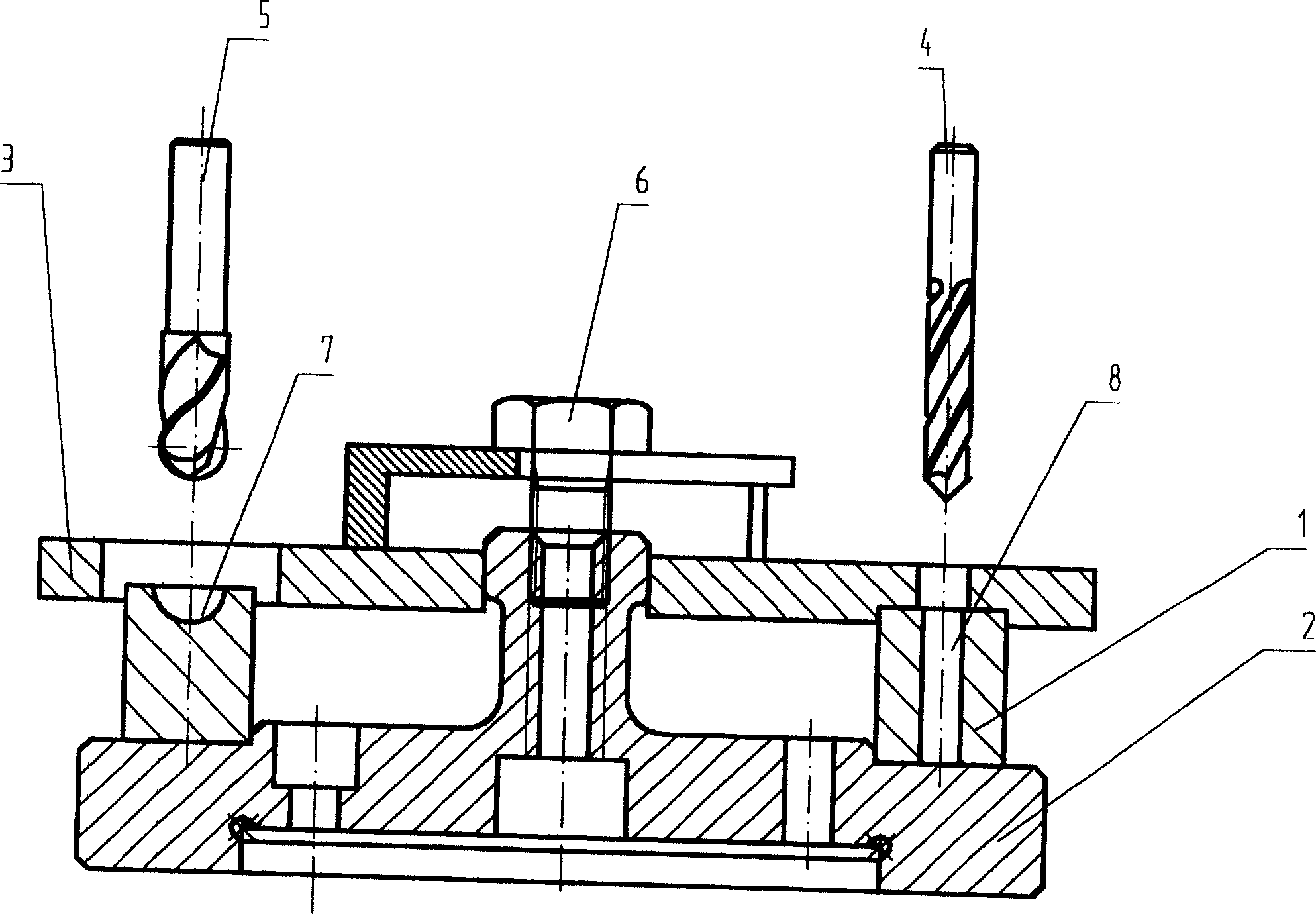

[0015] The present invention is a brass or bronze cage. The specific processing steps are as follows: According to the traditional method, the blank is cut off by a lathe for outer diameter, inner diameter, and turning end, and then processed into a single half-piece annular cage, and the outer diameter is softly ground, and the inner diameter is finely turned. After positioning the inner diameter and end face of the single half-piece annular cage 1 through the support plate 2 and the pressure plate 3, use the compression screw 6 to axially compress, and the machine tool automatically selects the spindle speed and feed rate according to the program. Use the spherical milling cutter 5 from the end face The direction is along the axial direction, and the plunge-cut milling first roughs out the shape of the spherical pocket, and then uses the fine milling cutter to process the required spherical size and shape tolerance. After the milling of the hemispherical pocket hole is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com