Four-freedom face-down spline connecting head

A bonding head and degree of freedom technology, applied in transportation and packaging, furnace, electric charge manipulation, etc., can solve the problems of easy to produce singular shapes, reduce working space, and low manufacturing precision, and meet the requirements of large stroke rotation, Strong load capacity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

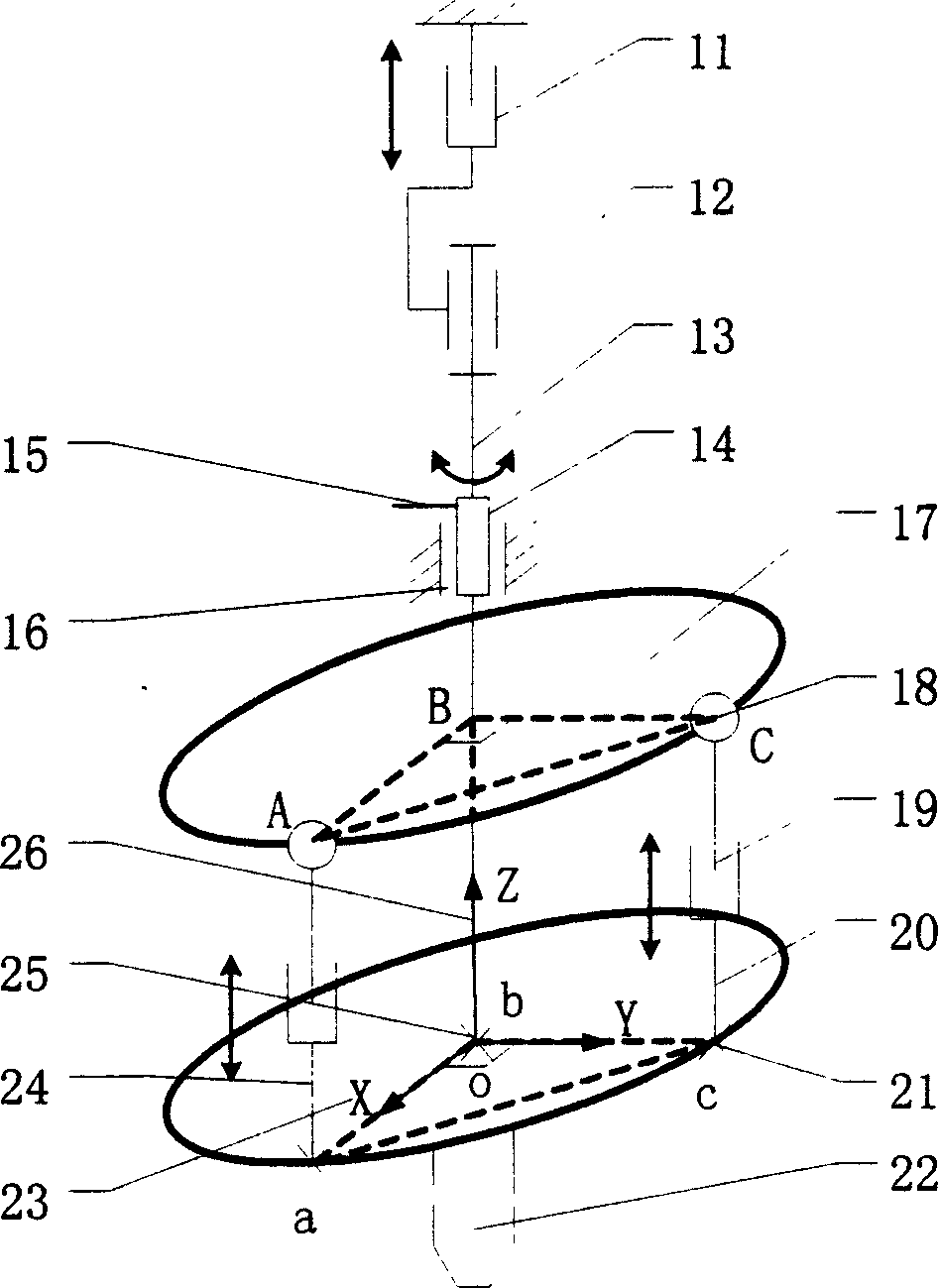

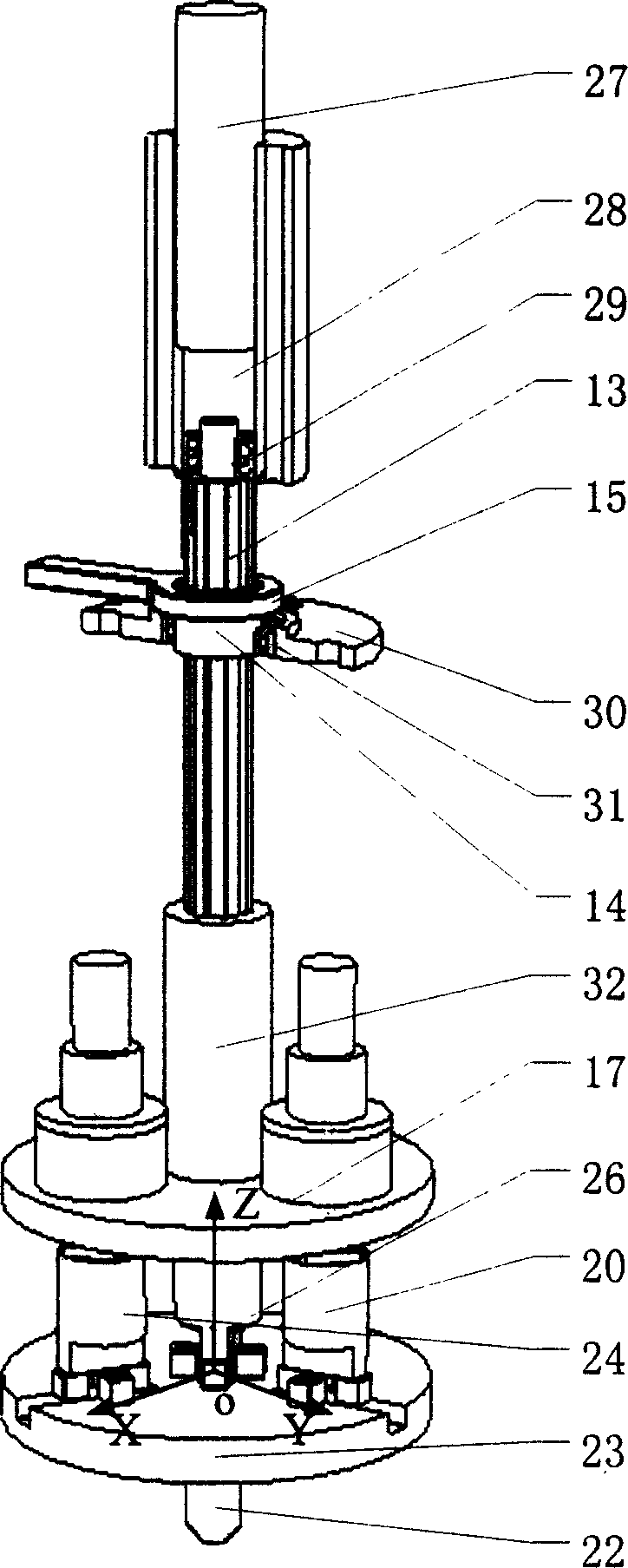

[0019] Such as figure 1 As shown, it includes a two-degree-of-freedom series mechanism based on a ball spline pair, a two-degree-of-freedom parallel mechanism and a suction nozzle.

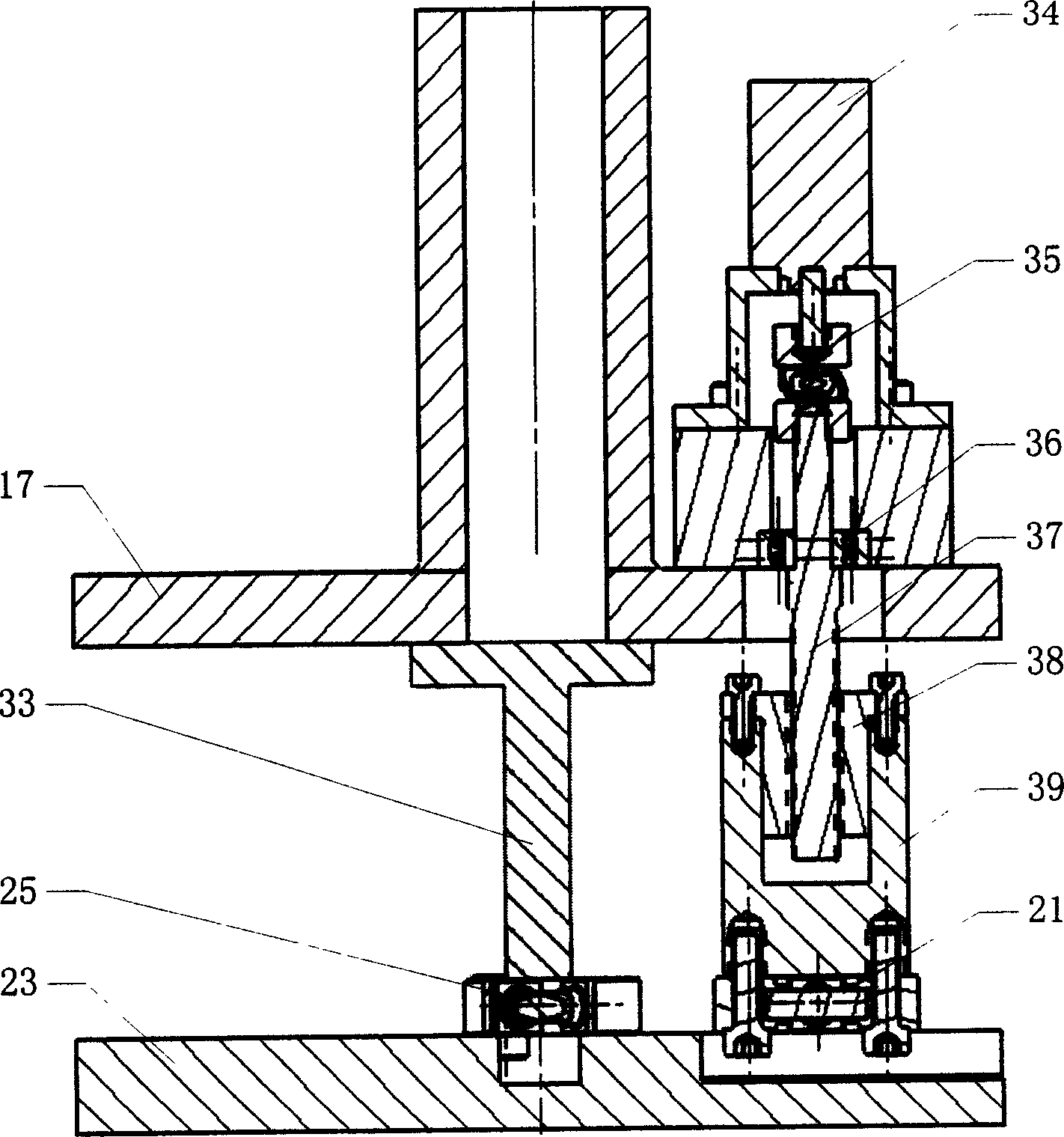

[0020] In the two-degree-of-freedom series mechanism, one end of the ball spline shaft 13 is connected to the slider 11 through the first rotating pair 12, and the other end is fixedly connected to the upper platform 17 of the parallel mechanism, and the flip-chip bonding head is realized by moving the slider 11 Movement along the Z direction: the sleeve 14 of the ball spline pair is fixedly connected to the frame through the second rotating pair 16, and the rotation of the flip-chip bonding head around the Z direction is realized by driving the shift fork 15 fixedly connected to the sleeve.

[0021] The above-mentioned parallel mechanism consists of an upper platform 17, a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com