Air electrode of multi-layer sintering structure and its manufacturing method

An air electrode and manufacturing method technology, applied in battery electrodes, structural parts, fuel cell half-cells and primary battery-type half-cells, etc., can solve electrolyte dilution, internal zinc anode moisture content cannot be stored for a long time, hinder Zinc-air battery performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

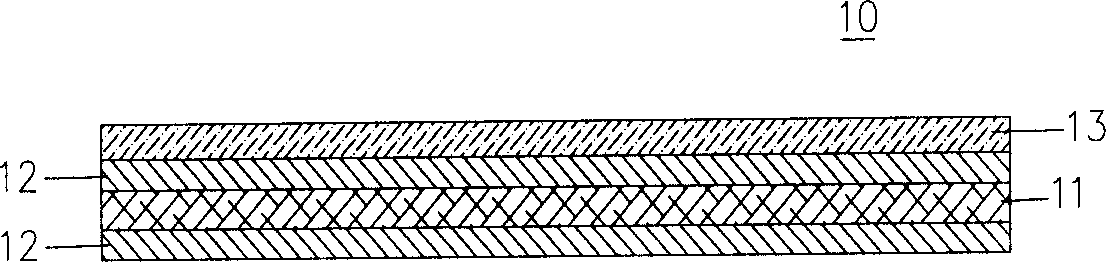

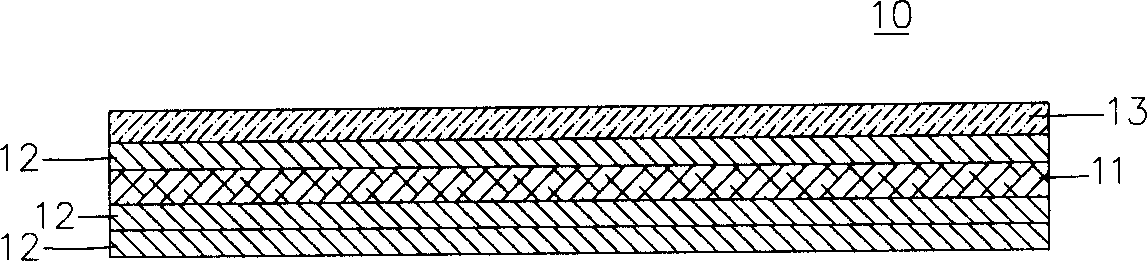

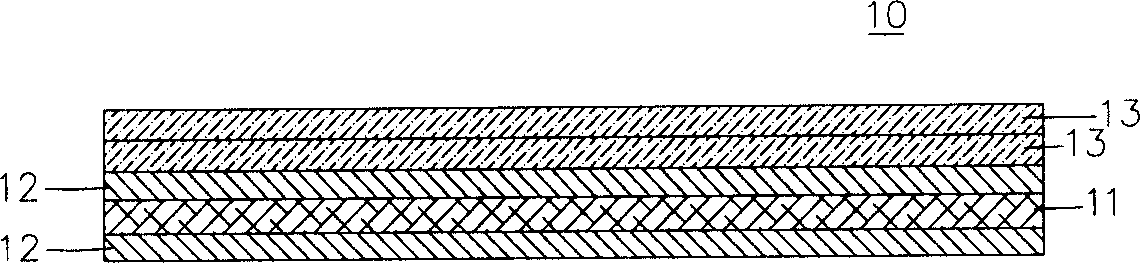

[0053] The air electrode 10 of the present embodiment has a structure such as figure 1 As shown, the nickel mesh is used as the base material 11 and the current collector constituting the air electrode 10. A layer of diffusion layer 12 is stacked on the upper and lower sides of the nickel mesh, and the outer surface of the diffusion layer 12 on the upper side of the base material 11, Another layer of activation layer 13 is laminated. The thickness of the air electrode 10 is 0.8mm, and the density range is 0.1-30.0g / cm 3 ,

[0054] Wherein, the manufacturing method of the diffusion layer 12 is to mix hydrophobic coking carbon black with polytetrafluoroethylene (PTFE) adhesive and deionized water in a ratio of 3:1:50, then dry it, and then coat it on the nickel mesh. The upper and lower sides are made after sintering at 200°C for 20 minutes; and the activation layer 13 is made by using hydrophilic coking carbon black, polytetrafluoroethylene (PTFE) adhesive, and transition met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com