Three-D low-sensitive bus-bar line and manufacturing method thereof

A low-inductance busbar, three-dimensional technology, used in cable/conductor manufacturing, busbar installation, electrical components, etc., can solve the problem of inability to make full use of limited space, restricting the application range of low-inductance busbars, and high production costs. The effect of low impedance, improved efficiency and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

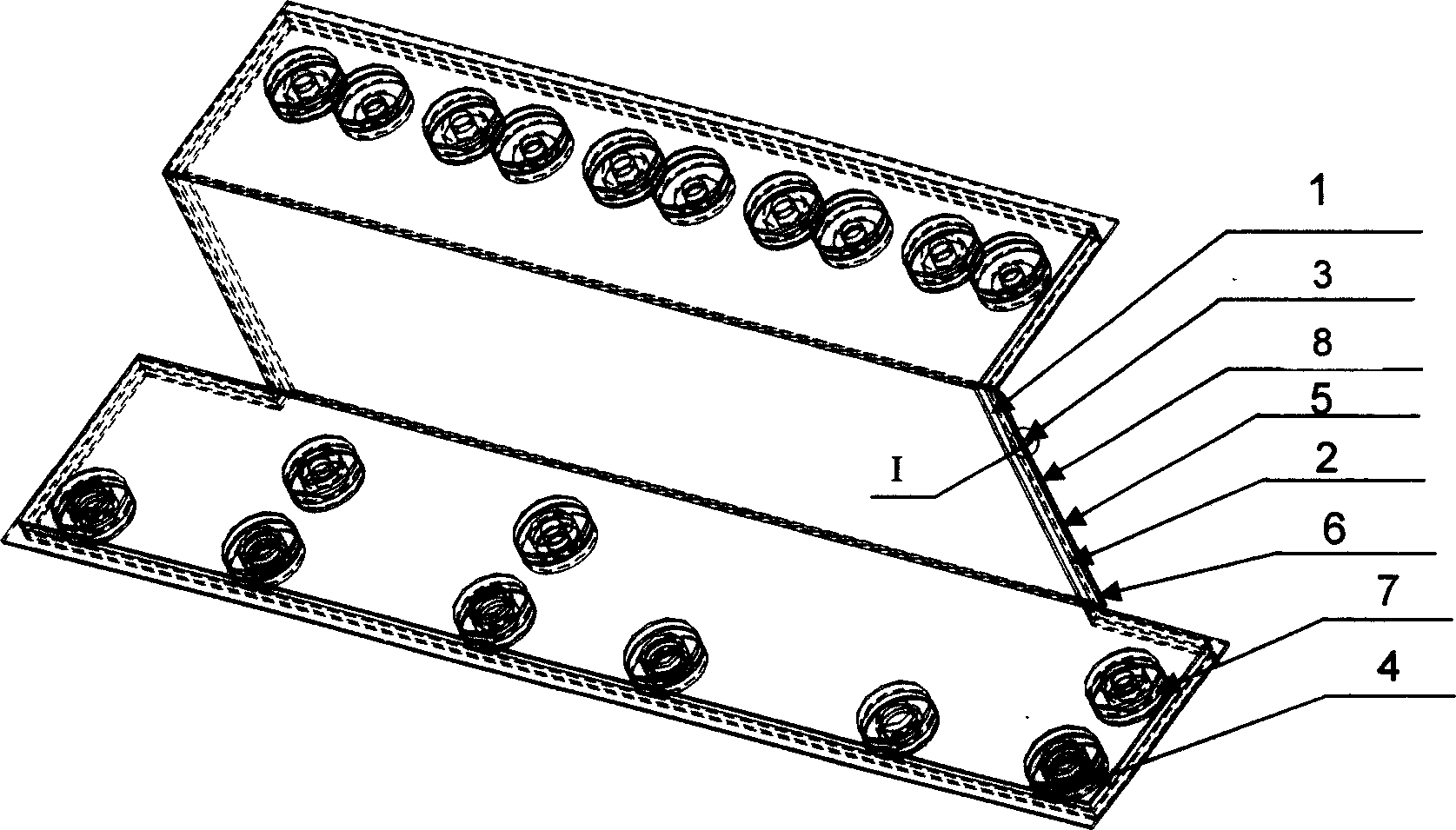

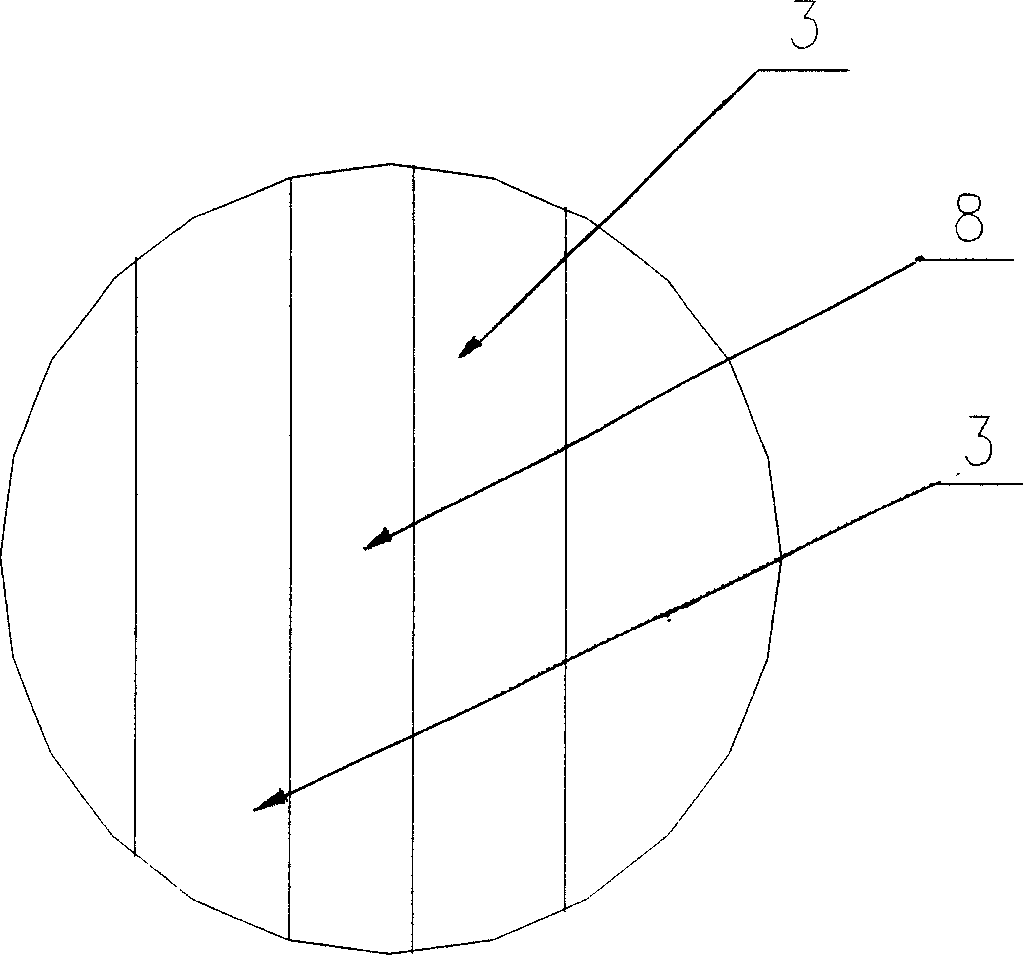

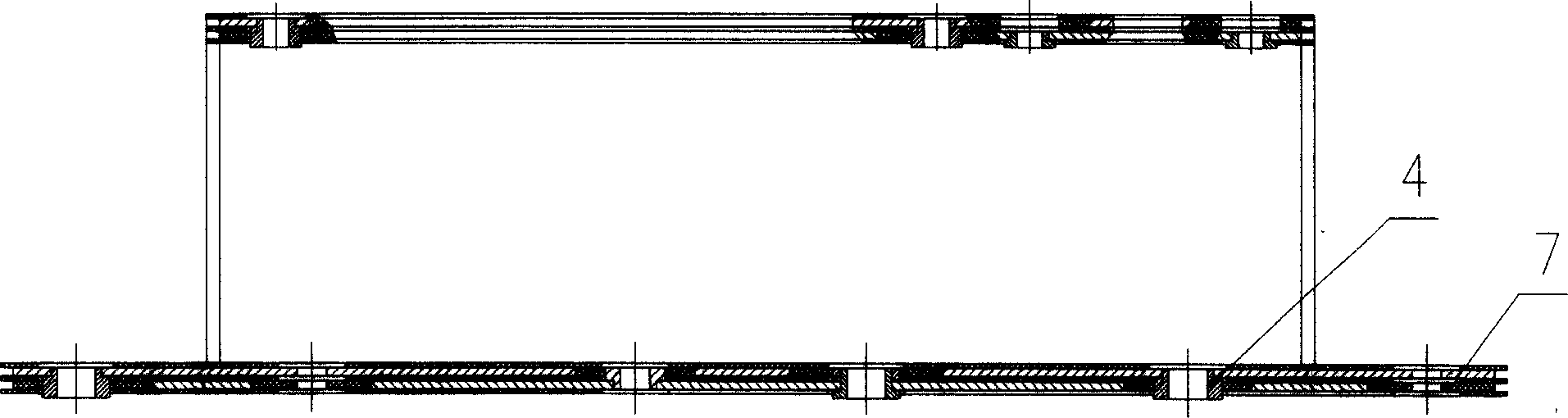

[0014] Referring to the accompanying drawings, this embodiment is a three-fold low-sensitivity busbar. Between the upper polyimide film insulating layer 1 and the middle polyimide film insulating layer 3 is the negative busbar 2 (that is, the copper plate conductive layer 2), and between the middle polyimide film insulating layer 3 and the lower polyimide film Between the amine film insulating layers 5 is the positive busbar 6 (that is, the copper plate conductive layer 6); an insulating pad 7 is installed at some openings of the busbar; copper sleeves 4 are riveted at the remaining openings of the busbar.

[0015] Its manufacturing process includes the following steps: (1) punching the copper plate; (2) bending the punched copper plate into the shape shown in the figure; (3) deburring; (4) tinning; (5) cleaning; (6) Lamination Laminate the copper bar that has been manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com