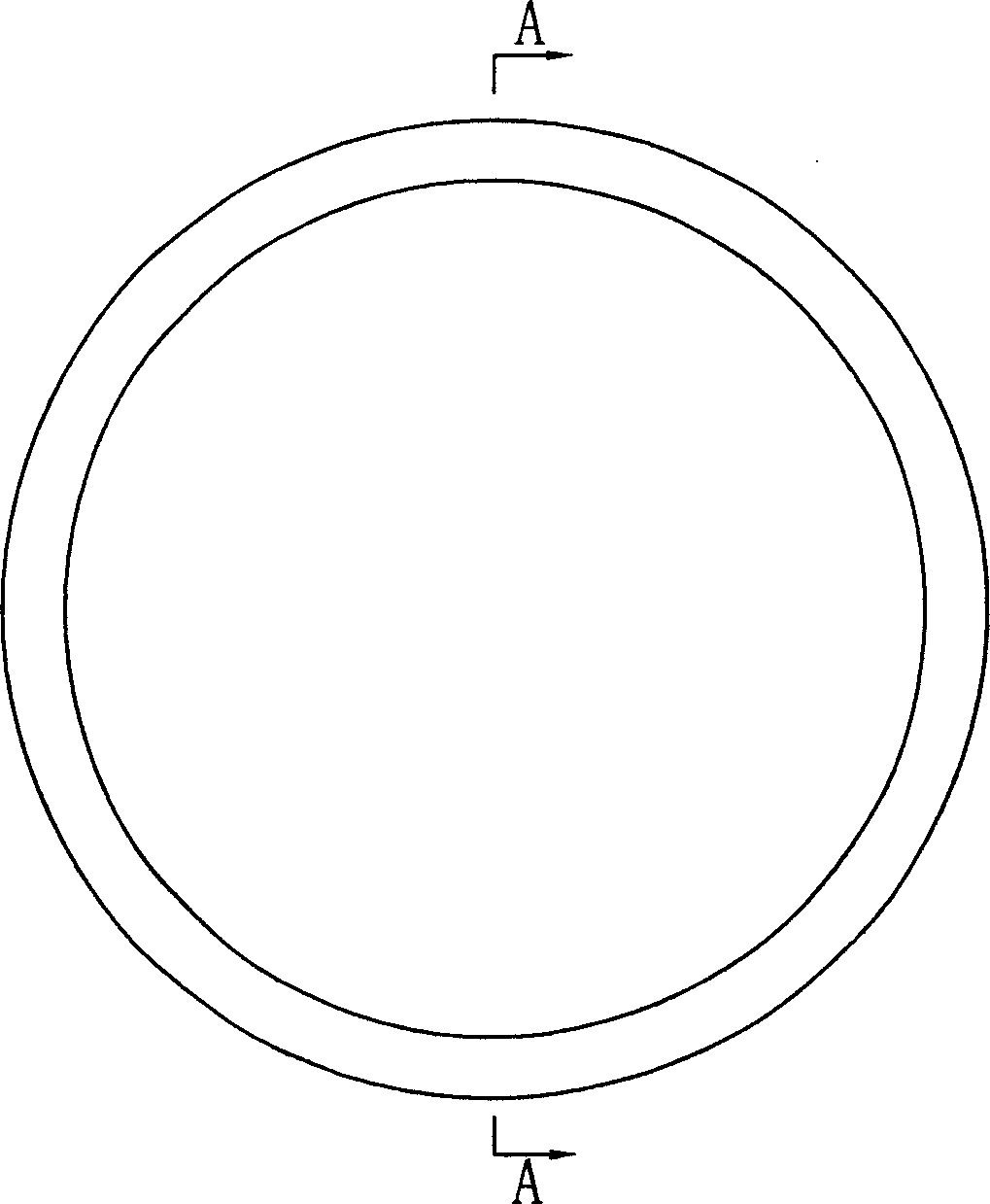

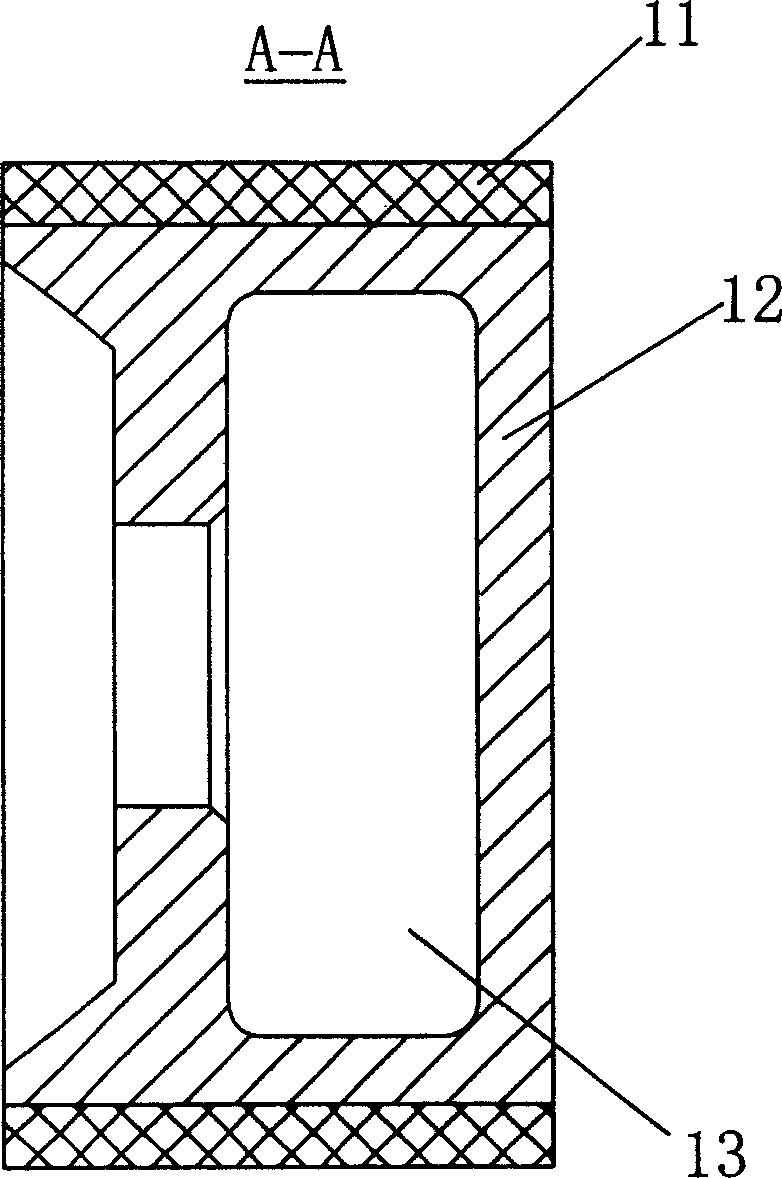

High temperature and erosion resistant centrifugal roller and its manufacturing method

A manufacturing method and technology for centrifugal rollers, applied in the field of centrifuges, can solve the problems of easy thermal deformation of the roller blank, easy expansion and cracking of the surface of the roller, reduced cotton yield and product quality, etc. The effect of increasing the number of reuses and reducing the difficulty of combining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] After an in-depth analysis of the reasons for the above-mentioned defects of the existing centrifugal roll with a stainless protective layer, it is found that the material of the stainless steel protective layer is quite different from that of the roll blank, and the thermal conductivity of stainless steel is not as good as that of the roll blank. The billet is easily deformed when heated, and it is difficult to reuse. At the same time, due to the difference in thermal conductivity between the two, the cooling effect is not understood. In addition, since stainless steel is a high-alloy steel, as the alloy content increases, the quenching sensitivity of the steel during welding will increase, which will increase the hardness and brittleness of the joint part and the internal stress. At the same time, the expansion system will increase due to the decrease in thermal conductivity. , the internal stress of the joint part becomes larger, which makes the roll blank easy to def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com