Multipoint blank holder force variable hydraulic press

A technology of variable blank-holding force and press, which is applied in the field of sheet metal stamping and forming, and can solve problems such as changes in blank-holding force and low precision of blank-holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

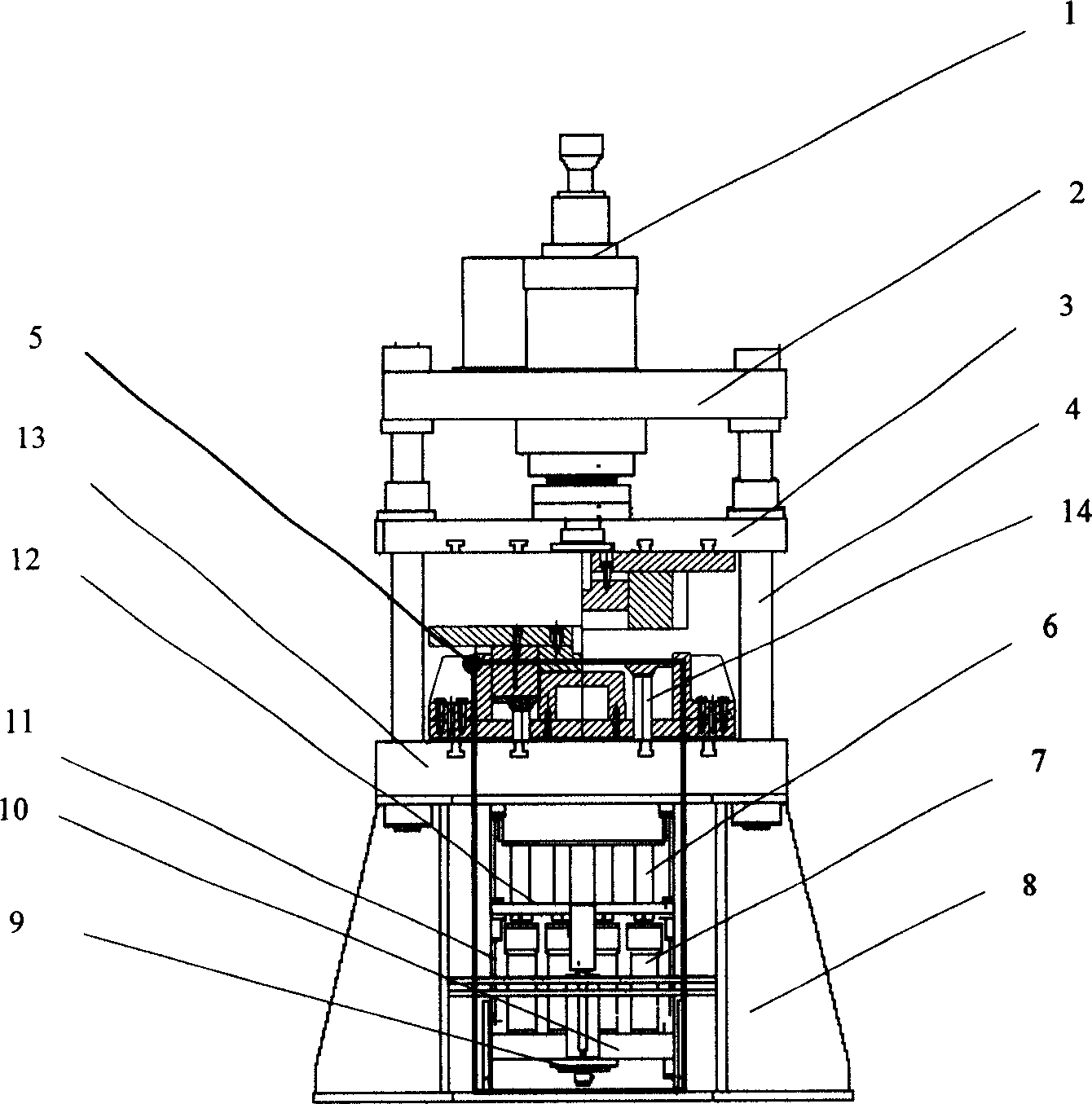

[0009] Such as figure 1 As shown, the present invention comprises: main cylinder 1, crossbeam 2, slide block 3, column 4, base 8, workbench 13 and hydraulic drawing pad mechanism 5, and its connection relation is: main cylinder 1 is fixed on crossbeam 2, and main cylinder The piston of 1 is connected to the slider 3, the slider 3 slides up and down along the column 4, the hydraulic drawing pad mechanism 5 is set at the lower part of the workbench 13, the base 8 supports the above components, and the frame is fixed on the ground with anchor bolts .

[0010] The hydraulic drawing pad mechanism 5 includes: connecting rod 6, several blank holder cylinders 7, jacking cylinder 9, bottom plate 10, pull down rod 11, drawing backing plate 12, ejector rod 14, and its connection relationship is: blank holder cylinder 7 The jacking cylinder 9 is fixed on the bottom plate 10, the upper end of the pull rod 11 is connected with the worktable 13, and the lower end is connected with the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com