Anchor cable stress sensor for optical fiber grating dynamometer

A stress sensor, fiber grating technology, applied in the measurement of fluid pressure, by measuring the change of optical properties of materials when they are stressed, instruments and other directions, can solve problems such as redundancy, and avoid redundancy and organic matter. The effect of easy fatigue decomposition, improved sensing performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

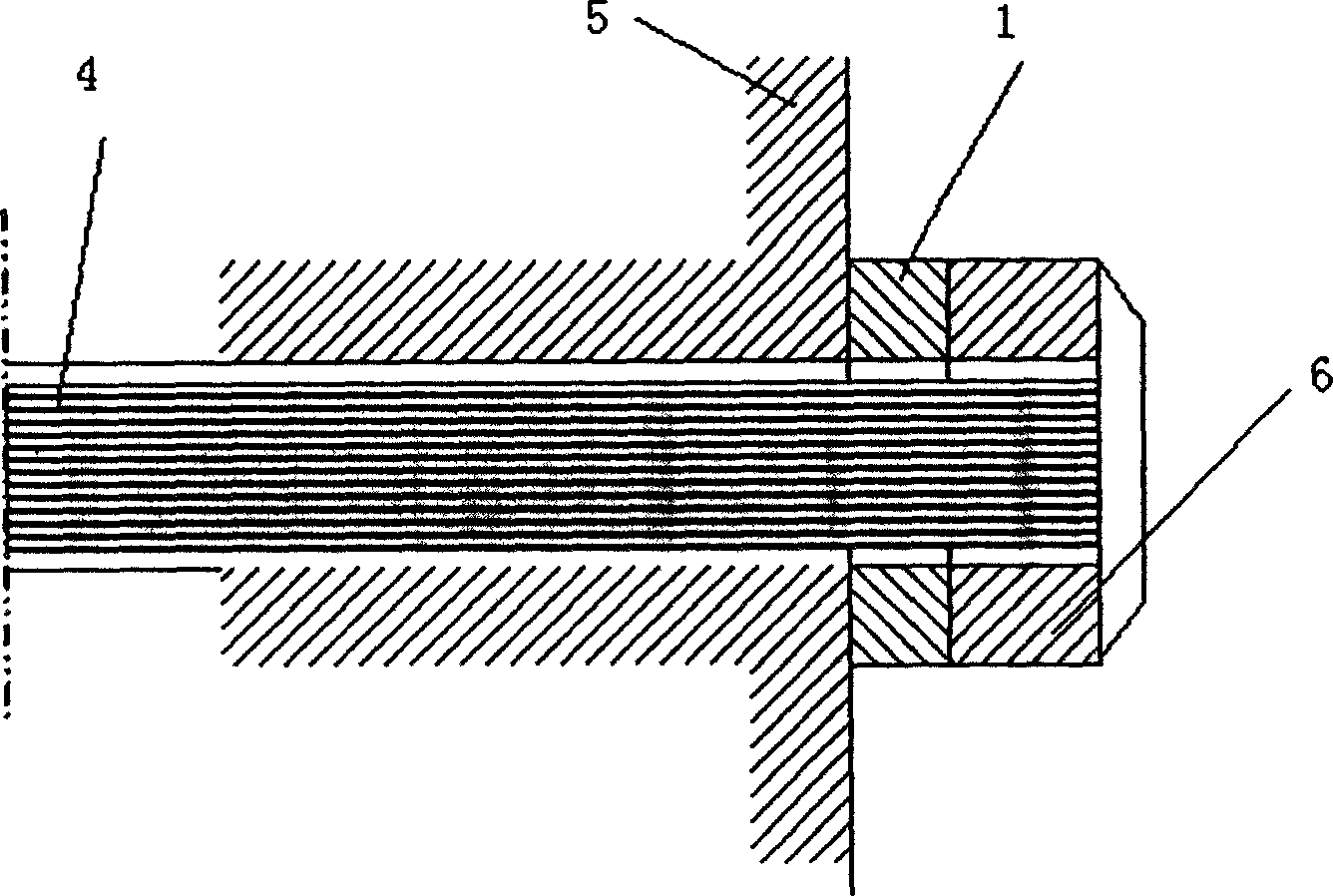

[0014] The fiber grating dynamometer anchor cable stress sensor structure is as follows figure 1. As shown, it includes 1-annular elastic body, 2-fiber grating stress sensor, 3-fiber grating temperature sensor, 8-optical cable outlet seat, 9-optical cable and other parts. Among them, the fiber grating stress sensor and the fiber grating temperature sensor are prepared by glue-free packaging technology; the fiber grating stress sensor, the fiber grating temperature sensor and the annular elastic body are attached by laser spot welding 14, and the welding direction of the fiber grating temperature sensor is perpendicular to the ring The direction of stress on the elastic body. As mentioned above, the fiber grating dynamometer anchor cable stress sensor structure, in which six fiber grating stress sensors 2 are evenly distributed on the outer surface and inner surface of the annular elastic body, are welded by a laser welding machine, and the welding direction is parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com