Universal optical wave plate detector with high reproducibility

A general-purpose optical and reproducible technology, applied in the field of optical measurement, can solve problems such as low measurement efficiency and complex instruments, and achieve the effects of strong versatility, high measurement accuracy and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

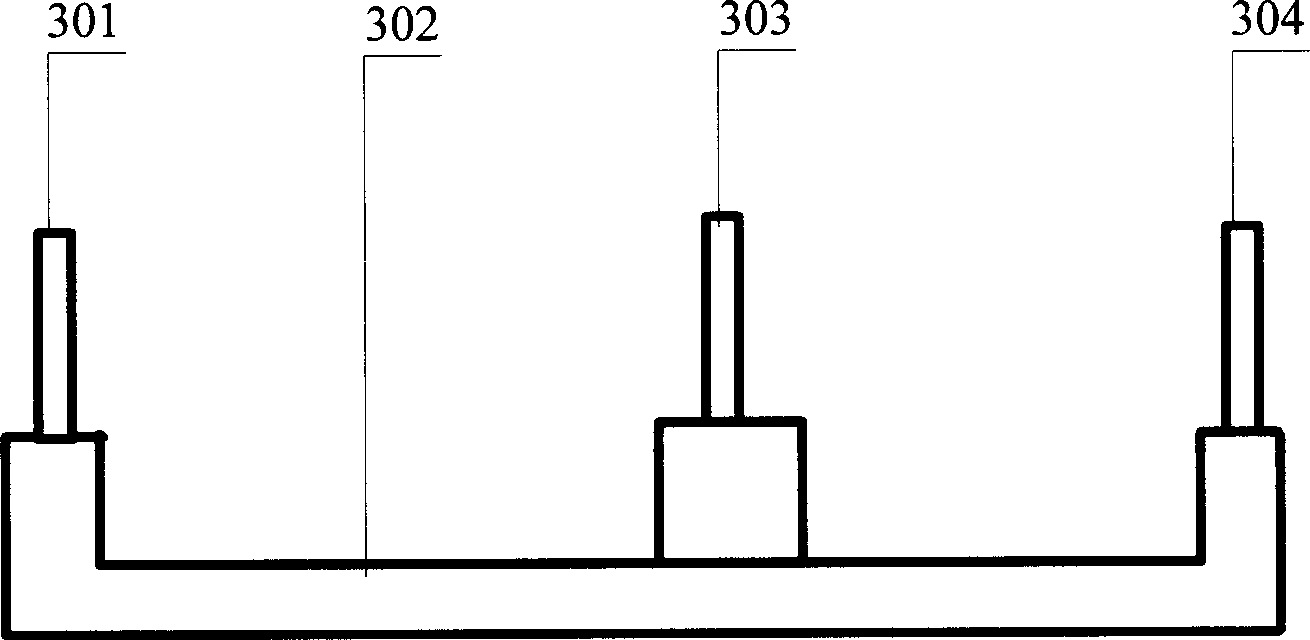

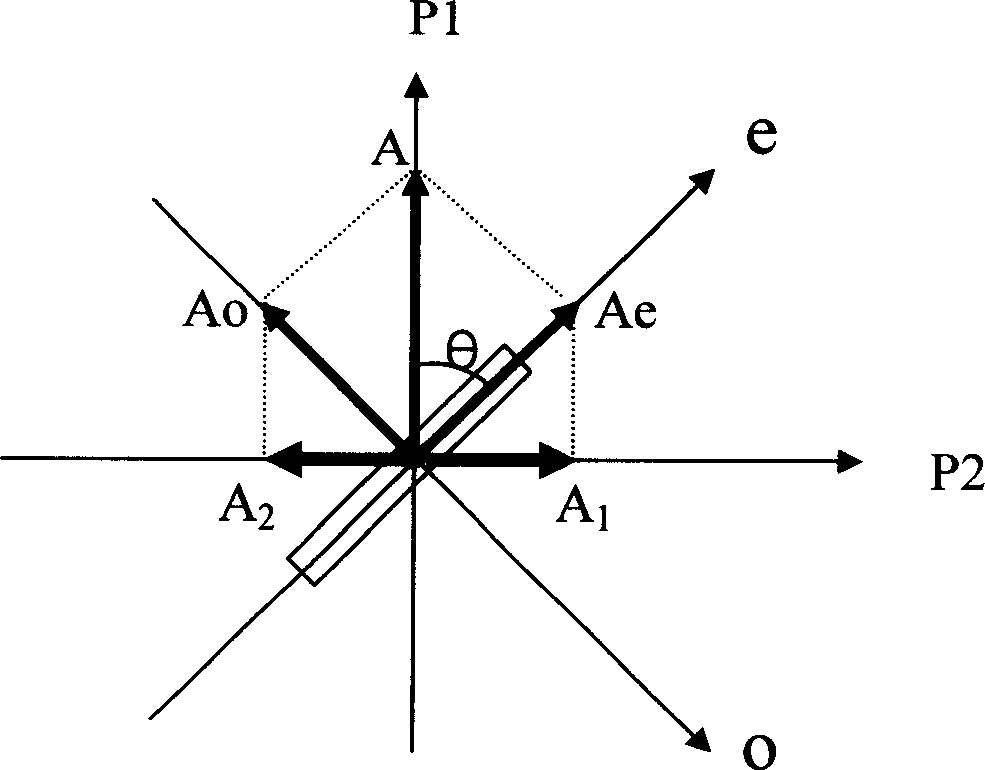

[0021] A specific embodiment of the high-reproducibility universal optical wave plate detector of the present invention is as figure 1 As shown, it includes a white light source 1 , a beam splitter 2 , an embedded measurement table 3 and a photodetector 4 . The system also includes an analog-to-digital converter 5 , a computer 6 and a controller 7 . The outgoing light of the white light source 1 is incident on the beam splitter 2 to obtain a monochromatic beam, and then the beam is incident on the embedded measurement table 3, and the embedded sample table 3 is used to polarize the monochromatic incident light after passing through the beam splitter 2, and placed to be Measure the sample, and the effect on the polarization analysis of the outgoing light. A polarizer 301 , a wave plate to be measured 303 and a polarizer 304 are fixed on the embedded measurement frame 302 . The polarizer 303 and the analyzer 304 can be various polarizing prisms or other high-performance polari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com